The “Turning Data into Action” series covers five features of transportation management software systems that can help you see quick results with your fleet’s strategies. Click here to see Part 1, which covers real-time roadmapping.. Part 2, below, covers preventing failures and keeping commitments. Part 3 covers instant rewards for drivers and automated dispatch. Click here to see it.

2. Preventing failures

In order to prevent customer service failures, TMS systems can identify current and future conflicts due to drivers’ HOS availability and other potential problems.

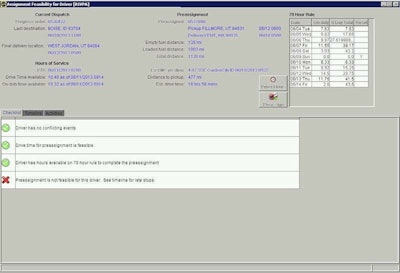

McLeod Software’s Driver Feasibility decision support tool – accessible from within the LoadMaster load planning screen – gives users an instant graphical analysis of all possible driver-load assignments that are closest to a pickup location.

The tool does not calculate the optimal driver-load combinations for an entire network. Rather, it displays driver schedules on a graphical timeline to show a given load assignment’s feasibility given the driver’s current and projected hours of service, location, load status and availability.

The Driver Feasibility feature in McLeod Software’s LoadMaster TMS platform displays scheduling conflicts for potential driver-load assignments.

The Driver Feasibility feature in McLeod Software’s LoadMaster TMS platform displays scheduling conflicts for potential driver-load assignments.“The idea is to allow customer service people to take a driver and anticipate if they are able to take an assignment based on a number of factors,” says Robert Brothers, director of product development. “It is a front-end strategy to eliminate service failures.”

Using the integration between TMS systems and onboard computing platforms is a main customer service strategy for Oak Creek, Wis.-based Preferred Carrier Logistics. If all of its load assignments aren’t compliant with HOS rules, a service failure may result. The 29-truck expedited hauler has real-time HOS information available within its cloud-based Sylectus TMS system.

With drivers’ HOS status visible, dispatchers have everything they need to make decisions on one load board. “You have to have a way to look at hours of service,” says Craig Aimers, general manager. “If you go back a year, I don’t think shippers cared as much as long as you could pick up and deliver freight the next day. Now they care if it is happening legally.”

Besides using technology to prevent scheduling conflicts, carriers can boost customer service by having accurate information for when drivers will be available for the next assignment. When planning future loads, dispatchers use projections for when drivers will become available – otherwise known as the projected time available, or PTA.

Most systems rely on manual input of this data from drivers and dispatchers; that’s because a projection may not be accurate since conditions can change from the time a PTA is entered – or updated – to when a driver actually is available.

The IDSC Match Advice load optimization software from TMW Systems is able to match drivers with loads at the precise moment they change their status from loaded to empty. This immediate status is obtained through integration with TMS platforms, says Frank Mabry, director of professional services for TMW.

3. Keeping commitments

Executing a strategy also means making and keeping commitments. TMS systems have many features to give fleet managers proactive visibility to information needed to manage commitments with customers and drivers.

One feature allows metrics to be displayed within load planning screens to help planners keep mileage and pay commitments with drivers by prioritizing loads as they become available.

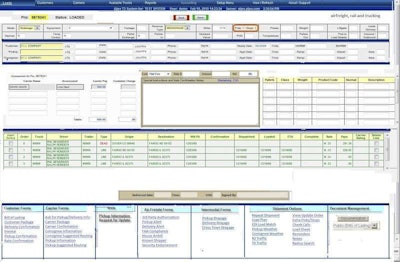

Since Aljex Software’s Web-hosted TMS system for carriers is a cloud-based system, companies quickly are able to set up portals for drivers to view data.

Since Aljex Software’s Web-hosted TMS system for carriers is a cloud-based system, companies quickly are able to set up portals for drivers to view data.The Sylectus TMS platform uses several metrics in its planning screen that relate to driver commitments. One metric, Last Available (LA), shows the time expired since drivers last indicated they were available for dispatch. This metric is located next to another metric that shows the time expired since the driver emptied the Last Load (LL).

By using both metrics to make a fair assessment, dispatchers can prioritize drivers for loads according to who has been waiting the longest for a reload. One driver could be returning from a vacation and thus have a long LL time; when this driver returns to work, the LA time begins to accrue. Reloading this driver would take priority over another driver with a lower LL time if the two drivers had similar LA times.

Sylectus also shows each driver’s current earnings as a percentage of their weekly and monthly goals. The information helps fleet managers be more proactive with driver retention, says Stuart Sutton, president of Sylectus.

Preferred Carrier Logistics’ Aimers agrees, adding that his strategy for using the metrics is broader than keeping drivers happy. “We are trying to maximize driver pay,” he says. “If a driver is making money, everyone is making money.”

Click here to see Part 1 of this story. See Part 3 Monday.