Carrier’s hybrid Vector TRUs such as the 8500 use the company’s E-Drive all-electric refrigeration technology.

Carrier’s hybrid Vector TRUs such as the 8500 use the company’s E-Drive all-electric refrigeration technology.After a brief flurry of activity a few years ago, hybrid technology for heavy-duty trucks and tractors largely has faded from view in the industry. But it continues to reap dividends in the automotive and light-duty truck markets, and now it appears that hybrid technology is changing the way refrigerated fleets will keep their cargos cold en route to market.

David Kiefer, director of sales, marketing and product management for Carrier Transicold, says hybrid reefers offer fleets a wide array of benefits that simply are not possible with conventional diesel-only trailer refrigeration units. Chief among those are fuel savings, quieter operation and reduced maintenance, he says.

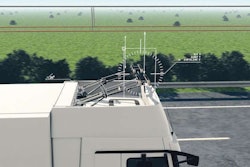

Carrier’s hybrid Vector TRUs use the company’s E-Drive all-electric refrigeration technology. When mobile, the Vector system is powered by a 21 kVA generator coupled to the diesel engine, and when stationary, the unit can be plugged into an electric power supply to run like a large sophisticated electric refrigerator. This standby power capability enables the diesel engine to be shut down, eliminating noise and emissions while conserving fuel.

Additional hybrid-specific design benefits also allow the unit’s electric architecture to be streamlined compared to conventional belt-driven mechanical systems and semi-electric systems, Kiefer says. Eliminating mechanical parts such as belts, fan shafts, pulleys, clutches and vibrasorbers that require service and periodic replacement reduces service requirements and costs.

“Many mechanical parts that are subject to wear and tear are simply not required,” he says. “In short, if it’s not there, it can’t break.”

Fuel eye-opener

Perhaps the real eye-opener for fleets is the fuel savings these units offer. Kiefer says hybrid units are up to 26 percent more fuel-efficient than conventional systems while delivering even higher cooling capacities using less power.

“This results in 5 to 30 percent more Btus of cooling per gallon of fuel,” he says. “With electric-standby capability, drivers can tap into electric power supplies to run the system when parked for loading and unloading, or rest breaks at truck stops equipped with power receptacles.”

The lower cost of electricity versus diesel fuel means operating costs can be reduced by up to 70 percent compared to diesel operations, Kiefer says. And when operating on standby, engine run-time hours are reduced, helping to further extend service intervals and reduce maintenance costs.

From a driver perspective, there is no significant difference in operation of Carrier’s hybrid Vector units compared to conventional belt-driven units, Kiefer says. Fleets wishing to take advantage of electric standby should add the needed electric infrastructure in their distribution centers, including power receptacles at loading docks and parking areas.

Maintenance adjustments to service hybrid reefers also have been minimal. “Technicians need to learn how to work with the electric facets of the system,” Keifer says. “But interestingly, since the hybrid Vector units eliminate many traditional components that require adjusting and frequent replacement, the units can actually be easier to service than mechanical systems.”