This is the first time Trucking Efficiency has convened a new study team of experts to investigate a technology on which it has already issued a Confidence Report. The group says this is due to refinements in the way fleets are implementing 6×2 axles and the accompanying technologies that are being used alongside 6x2s.

“While we found that the fuel savings benefits as well as the challenges from the original report are largely still true, new product refinements are coming to the market that are aimed at addressing some of the concerns fleets had about 6×2 axles,” says Yunsu Park, NACFE study team manager. “For instance, fleets dedicated to 6x2s are improving tire wear by changing the tire models they use and limiting the torque when launching the truck. Also, driver training is a significant part of a successful 6×2 implementation.”

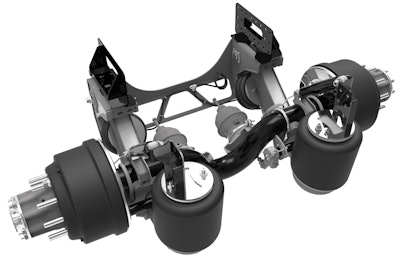

According to Trucking Efficiency, the study team identified three generations of 6×2 products, focusing special attention on Generation III products, which contain liftable pusher axles, automatic load-sensing/load shifting, and traction control.

The original 6×2 Confidence Report published in 2014 concluded that adoption of 6×2 axles would double every year. Trucking Efficiency says this has not happened in large part because the challenges and consequences of switching to 6×2 were greater than the original study team anticipated. Mike Roeth, Trucking Efficiency operation lead, notes tire wear and driver engagement and adoption as two specific challenge areas, as well as manufacturing limitations.

“I think in some instances a fleet may want to spec X, Y and Z features and they can get them in a 6×4, but because of lower adoption rates, the [truck] builders have not engineering those features into their 6×2 options,” Roeth says.

Additionally, Trucking Efficiency says improving 6×4 systems, residual value issues for 6×2 units and lower diesel prices that have stretched out the payback period for 6×2 systems also have impacted overall industry acceptance. That said, Roeth says manufacturers are continuing to work on improving their offerings, and fleets that have invested in 6x2s continue to do so. He specifically notes smaller fleets as an area where the 6×2 interest and adoption seems to grow.

“The fuel-savings potential, combined with a skeptical industry on the technology, has spurred some interesting innovations with respect to 6x2s,” he says. “Those fleets dedicated to 6x2s and exploiting the various opportunities are finding they return their investment.”

Trucking Efficiency also says 6×2 axles are one of several technologies that will be featured during Run on Less—a first-of-its-kind cross-country roadshow to showcase advancements in fuel efficiency.