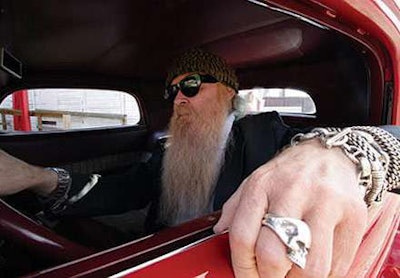

If you like ZZ Top’s music, you know that BFG always goes for a heavy, heavy guitar tone. And he always assumed his blues heroes, like B.B., strung their guitars with the heaviest-gauge strings they could find to get that sound, too. So naturally, that’s how he strung his guitars.

But out on stage, to his surprise, the good Reverend Gibbons discovered that the strings on B.B.’s beloved “Lucille” were the absolute lightest-gauge available. After the show, Gibbons asked B.B. why he used such light strings.

B.B. laughed jovially, the way we’ve all seen him do on TV over the years, and turned the question around on Billy. “What I want to know, young man,” the Blues Master asked with a twinkle in his eye, “is why you workin’ so hard?”

B.B.’s message is pretty straightforward: If you’ve got the skills to do the job right, why on earth work harder at it than you have to?

I think of B.B.’s lesson a lot these days whenever I hear someone tell me automated gearboxes are crap. Or that real truck drivers use manual gearboxes. Wannabe truck drivers use AMTs. Or that they don’t feel in control of a truck equipped with an AMT.

And I always think the same thing: Man… Why you workin’ so hard…?

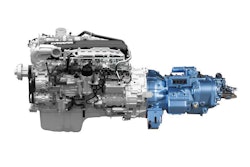

If you have any doubts about the way the market for automated manual transmissions is breaking, then click on this story here for your answer.

Con-way Truckload just pulled the purchase trigger on 635 new Class 8 tractors. And not a single one of them will be spec’d with a manual gearbox. According to Con-way Truckload president, Joseph Dagnese, driver comfort and safety were the overriding concerns driving the decision. He also cited industry polling, which clearly shows that AMTs are the preferred transmission choice for new drivers entering trucking. Moreover, AMTs are swiftly gaining ground with experienced drivers who find they don’t actually miss continually engaging a clutch pedal and shifting gears as much as they thought they would.

You can put me down in the “Not Surprised” category on this news story. I was recently talking to a friend who manages a fleet in Ohio. I asked him if he was having any problems with AMTs. “Oh, yeah,” he replied. “Big problems! I can’t get any of them on the new trucks I’ve ordered until July!”

As we talked, he told me there simply are no maintenance issues at all with new AMTs. Sure, you can get a bad gearbox from time to time. Or, more commonly, run into a ECM that isn’t functioning properly. But industry-wide maintenance issues? They just aren’t there.

As for acceptance in the industry…If I had a dollar for every time a fleet manager has told me about drivers threatening to quit if assigned an AMT-equipped truck, only to threaten to quit if they have to go back to a manual a couple weeks later, then I’d be able to buy a pretty decent bottle of whiskey with my profits.

For a long time, the skill required to efficiently operate a heavy-duty manual transmission was seen by many drivers as something that set them apart from drivers at large. Shifting gears on a big rig is both an art and a science. You can’t just pull someone in off the street and expect them be able to perform that task. It takes specialized training and, frankly, many years and hundreds of thousands of miles to master.

AMTs vastly simplify drivers’ jobs. But let’s be crystal clear about this: driving big rigs is still a dangerous job that demands an uncompromising attention to detail and total devotion to safety. You can take the best AMT in the world and put it in a truck, and you still can’t pull someone off the street, put them behind the wheel and expect them to perform at even a minimal level of proficiency.

Con-way Truckload put its money where its mouth is and invested in its drivers and their safety with this big tractor order. And they should be applauded for that move. AMTs work on the fleet side of the equation. And they work on the driver side of the equation.

More to the point, there’s going to be 635 Con-way Truckload drivers out on the road soon who aren’t going to be working near as hard as they used to. And that’s a good thing for everyone concerned.