Pressure Systems International President and CEO Tim Musgrave gathered up visitors and employees inside the company’s San Antonio manufacturing plant and revealed the good news.

As the old banner showing one million sales of auto-inflation systems was lowered from the wall another banner behind it came into view and commanded plenty of applause: 1.5 million systems sold.

A PSI employee holds a Meritor Tire Inflation System that was just produced minutes before in PSI’s San Antonio factory.

A PSI employee holds a Meritor Tire Inflation System that was just produced minutes before in PSI’s San Antonio factory.“This is something I don’t think very many people know,” Musgrave announced Wednesday. “We’re over 1.5 million now. I personally want to thank each of the individuals that work for us in every department.”

Musgrave’s team is eager to please. At the beginning of the plant tour during the Meritor & PSI 2019 Annual Fleet Technology Event, dozens of employees lined up at the plant’s entrance to greet fleet owners and managers and members of the media.

“If you take anything away, that’s all that I want you take away is that we’re here for you,” Musgrave said at the end of the tour. “We’re a team together. We work together. No one’s better than anyone else. Every one of us will do whatever it takes to do the job for you and the end-user.”

And that list of end-users is growing thanks to a longtime partnership with Meritor which markets PSI’s auto inflator through the Meritor Tire Inflation System (MTIS).

“You have the product focus of PSI which is singularly focused on tire solutions and you have the world class support of Meritor put together so it’s really an ideal mix,” James Sharkey, PSI vice-president of global sales and marketing, explained during a seminar prior to the tour.

PSI began working with Meritor in 1998.

“Since that time about 70 percent of all for-hire and private fleets have selected MTIS as their preferred tire inflation system,” Sharkey continued. “And again, that’s a pretty high adoption rate especially given the fact that it is an option.”

What are the measurable paybacks that keep attracting fleets? According to Sharkey, MTIS provides extended treadwear, improved fuel economy (up to 3.8 percent), is greenhouse gas compliant and can keep a punctured tire inflated long enough for a truck to return to the shop for service.

“One roadside call in many terms will basically pay for the system,” Sharkey said. “There’s also labor savings because you’re not changing out tires as frequently as you normally would. One fleet, documented, went from 16 months to 24 months in typical tire replacement.”

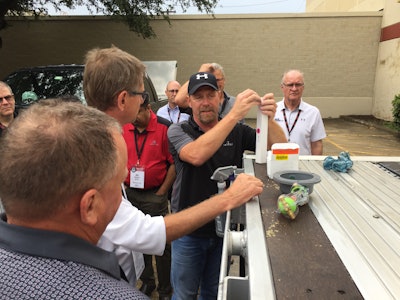

Velociti’s quality assurance manager, Pat Gober (center), shows how to install the Meritor Tire Inflation System (MTIS) at PSI’s manufacturing plant in San Antonio, Texas.

Velociti’s quality assurance manager, Pat Gober (center), shows how to install the Meritor Tire Inflation System (MTIS) at PSI’s manufacturing plant in San Antonio, Texas.Under-inflated tires not only have a shorter lifespan they can also lead to dangerous and costly blowouts on the road.

“The number one cause of service issues are tires. It’s a big problem,” said Al Cohn, PSI’s director of new market development and engineering support. “Under-inflation is the big issue. That’s where you generate all this heat. Heat is the worst enemy. Over 90 percent of road gators are due to under-inflation.”

Under-inflated tires also lead to a drop in fuel economy at a time when the North American Council for Freight Efficiency is expecting a rise in diesel prices.

“The good news is that in 2020 the engine emissions nightmare isn’t ours. It’s the shipping industry, the international maritime organization is the changing the law for all ocean-going ships whether it’s a cruise ship, intermodal containers, whatever,” said NACFE industry engagement director Dave Schaller, one of the tech event’s speakers. “They’ve got about four or five different ways they can go but the majority of the them will be burning something that’s very, very similar to our ultra-low sulfur diesel,” Schaller continued. “And those boys and girls have huge fuel tanks.”

PSI’s employees provided a tour at several sections within the factory where MTIS components are assembled and repeatedly tested.

PSI’s employees provided a tour at several sections within the factory where MTIS components are assembled and repeatedly tested.Schaller said the increased demand for ultra-low sulfur diesel will probably drive up diesel prices .25 to .50 cents per gallon as ships begin fueling up towards the end of this year and into 2020.

“So that’s a head’s up for you,” Schaller said. “We want you to think about how you’re spec’ing your equipment.”

Fleets with existing trailers can opt for a retrofit program courtesy of a partnership with Meritor and Velociti.

“Through the Instant ROI program, fleets and owner-operators can install MTIS on their existing trailers with Velociti’s deferred billing and extended payment plan that effectively utilizes the savings generated by the tire inflation system to pay for the solution,” Meritor reports.