California Governor Jerry Brown wants 5 million zero-emission vehicles on state roads by 2030. By the end of next month, one of them will be shuffling around the ports of SoCal.

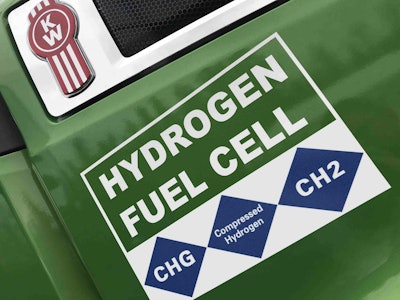

Kenworth’s hydrogen fuel cell Zero Emissions Cargo Transit (ZECT) T680 tractor, the fruit of a $7 million project between the Kirkland, Wash., truck-maker, the U.S. Department of Energy Office of Energy Efficiency and Renewable Energy and Southern California’s South Coast Air Quality Management District, has been undergoing testing in the Seattle-area since December and will head off to Total Transportation Services and the ports of Los Angeles and Long Beach in about six weeks.

This week, I was able to participate in the testing of the no-NOx daycab on the highways around Paccar’s Technical Center in Mt. Vernon, Wash.

With a range of 150 miles (upwards of 30 miles all-electric range) and a top speed of 65 mph, the tractor uses lithium-ion batteries to power a dual-rotor electric motor that drives the rear tandem axle through a four-speed automated transmission.

Loaded to just south of 79,000 pounds, the truck builds speed quickly and silently with the equivalent of about 565 horsepower and just more than 1,850 lb.ft. of torque. Kenworth Manager of Research and Development Brian Lindgren notes that while the motors are rated at 420 kW (565 hp) at a constant rate, they will peak higher. However, the company has limited the truck’s output to about 300 kW until the systems are validated.

The torque at launch is noteworthy but as the truck builds speed it begins to feel much more “normal.” But it certainly doesn’t sound normal. Other than the faint whine of the cooling fans, the truck doesn’t make much sound. With enough road noise you’ll forget you’re driving a hydrogen powered truck.

Six onboard tanks – 5 kg each and pressurized to 5,000 PSI – hold the equivalent of about 30 gallons of diesel and can be filled in less than 15 minutes. The Department of Energy estimates lists 39 hydrogen retail stations nationwide. The highest concentration is in California, but there are none in the 2,500 miles between California and South Carolina.

The Ballard Power Systems HC85 fuel cell – mounted where you would expect to find an MX engine – produces an electrical current of about 400 volts DC, which is converted to 650 volts DC and stored in the truck’s batteries, a one-ton bank mounted under the cab. With an expected battery life of six to 10 years, the zero emission T680 is equipped with battery heaters and chillers to limit the effect of weather on range.

The shift to electric mobility generally places an electric motor on each wheel but the T680 maintains a traditional driveline, with a dual rotor AC motor in the frame sending power via a shaft to a standard rear end. Moving motors to the wheels changes the unsprung dynamic characteristics of the axle. By not changing how the wheelends sit on the truck, Kenworth designers were able to spend more time developing the powertrain system.

The Kenworth T680 day cab’s fuel cell combines compressed hydrogen gas and air to produce electricity with only water vapor/steam emitted from a snorkel that exhausts near the roof of the truck. The electricity can power the dual-rotor electric motor to move the truck or recharge the batteries. In the event you end the day with less than a full battery charge, a 13kW onboard charger provides an overnight plug-in option.

The hybrid drive system manages the power from the fuel cell to and from the batteries, as well as the traction motors and other components, like the electrified power steering pump and the brakes’ air compressor.

The truck will make about 3,800 lb.-ft. of torque but that is limited to save wear and tear on a stock rear-end that is designed to handle roughly half that amount.

Shifting is handled through the back half of an Eaton Fuller 18 speed gearbox. It uses the same range and splitter, which provides a low-end ratio of about 4.3 and a direct top end. The lower-end ratio gives the truck excellent startability and enough torque to start up a 20 percent grade while the top-end gives the truck enough power to maintain 30 mph up a 6 percent grade – well above the average drayage speed of less than 20 mph.

Stephan Olsen, Kenworth director of product planning, says batteries themselves weigh-in at 2,000 pounds. The battery management platform, high voltage cable, coolant lines, enclosure and mounting adds about another 1,500 pounds. All that adds up to the ZECT tipping the scales at about 22,000 pounds – or about 3 tons more than a similarly equipped, diesel-powered T680.

“A lot of that comes from the batteries, some of that comes from cooling [system] and some of that comes from the hydrogen tanks,” says Lindgren.

Olsen says Kenworth testing has shown the hydrogen truck “performs equally as well, if not better than, current diesel trucks on the market.” From my brief time behind the wheel, I would agree.

Beyond the fuel cell itself, much of the T680 is stock equipment – including the suspension and Spicer D40-170P (5.38) rear end – and performed like you would expect a T680 to perform.

The ZECT is only expected to log about 50 miles per day, but the SoCal ports and Kenworth’s ZECT will play an important role in validating hydrogren’s role in trucking.