No longer simple iceboxes on wheels, refrigeration systems are evolving to include highly efficient, green data management solutions

There was a time when technological revolutions came in fits and starts. As a result, their impact on a business, industry or society tended to be fairly dramatic. But over the past two decades, the advent of computers and the subsequent quantum leaps in computing power have accelerated the pace of technological innovations to the point that today we constantly are bombarded with new products offering game-changing capabilities.

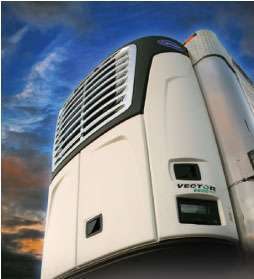

New hybrid reefer power units like Carrier Transicold’s Vector series save fuel in electric mode because the diesel engine is not used, eliminating associated emissions and noise.

A prime example of this unceasing technological push can be seen in fundamental changes now taking place in the reefer market. Until recently, the reefer’s evolution had been fairly straightforward and largely predictable. Early reefers used block ice and electric fans to keep loads frozen or cool. As mobile refrigerated systems came along, diesel-powered Freon-cooled trailers became commonplace. Various waves of newer, better insulating materials were the puzzle’s final piece, resulting in the more efficient reefer units that have dominated the industry for decades.

But if you thought reefer manufacturers had reached the pinnacle of their design arc, think again. The next generation of refrigeration technology now appearing on the market offers refrigerated fleets unprecedented leaps in terms of load quality, temperature control, fuel savings, data logging and remote operation. These new reefers use established technologies like cell phone networks, GPS, diesel-electric hybrid engines and the Internet to give fleets more control as to how they move refrigerated loads and the power to control costs while doing so.

Witte Brothers Exchange, a Troy, Mo.-based refrigerated fleet, began using Carrier Transicold’s hybrid Vector units in 2009 and was among the first to adopt diesel-electric reefer power for its trailers. “Like any fleet, we’re looking for a competitive edge,” says Brent Witte, president. “The status quo just isn’t good enough anymore, especially when you factor in 4-dollar-a-gallon diesel fuel and the push from our customers to adopt green technology.”

Witte sees future growth in the trucking industry coming in continuous steady waves rather than quick spurts over long periods of time. “Adopting technology that allows us to better control external costs such as fuel enables us to prepare for that new business reality,” he says.

Saving fuel and going green

Dave Kiefer, director of marketing and product management for Carrier Transicold, sees four key customer-driven trends that relate to current reefer technology developments. First, there is a widespread demand for improved fuel efficiency of transport refrigeration units. This ties in directly with the second trend: the ability to run the unit by electricity when parked – also called standby operation. Third and fourth, the dual push for “green” operations – both from customers seeking a marketing edge and the forthcoming federal greenhouse gas emissions regulations – has led to a demand for cleaner-running reefer units that simultaneously will reduce the unit’s overall carbon footprint.

A shift toward light- and medium-duty delivery vans for urban delivery of frozen and refrigerated goods has led Thermo King to develop a new line of smaller roof-mounted reefer power units for these vehicles.

Other key concerns include eliminating driver error, improving ease of use, customizing and optimizing performance, simplifying troubleshooting and maintenance, and greater use of telematics for remote monitoring and control. Carrier Transicold has addressed many of those issues through a new TRU control system and software applications that support it, Kiefer says.

Fleets are looking to vendors for more flexibility in how they go to market, says Doug Lenz, director of transport product management for Thermo King. “At the end of the day, what we’re really talking about is information, particularly fuel monitoring and metrics,” Lenz says. Going forward, new engines will give fleets dependable fuel consumption data so they can manage their operations better, understand their costs and potentially charge their customers more on their actual reefer use instead of estimated usage, he says.

New technologies give reefer fleets more control as to how they move loads and the power to control costs while doing so.

Hybrid diesel-electric reefer units have proven effective in reducing fleet fuel costs because they have the capability to run off electricity. “When (electric) standby is used during loading, unloading and staging, our Vector refrigerated power units save fuel because the diesel engine is not used, eliminating associated emissions and noise,” Kiefer says. These features are attractive for use at supermarkets and distribution facilities near residential areas. By using the diesel engine less, there is also less engine wear, helping to extend service intervals and longevity.

But while reefer fleets are seeking competitive advantages, government mandates such as greenhouse gas regulations will affect the reefer technology now being implemented. California law restricts current TRU engines to a useful life of seven years, requiring owners to modify their reefer units to a lower pollution standard. This requires either adding a particulate filter, repowering the unit with a new or newer engine, or buying an entirely new TRU. The cost for those choices runs between $4,500 and $20,000.

Today’s refrigerated trailer manufacturers face a continued need to lower tare weights and make trailers safer by way of roll stability systems.

Today’s reefer manufacturers have no control over this regulation, and until the final ultra-low pollution engines (Tier 4 Final) become available in 2014 ahead of the 2015 mandate, California still will require this seven-year cycle. “Additionally, there is a continued need to lower tare weights of reefer trailers and to make trailers safer by use of roll stability systems,” says Craig Bennett, senior vice president of sales and marketing for Utility Trailer.

Adding intermodal and medium duty

Another factor affecting reefer technology is the fact that the nature of the traditional line-haul transport business is evolving – primarily as a result of higher fuel prices and the unpredictable nature of fuel price spikes today.

“We’re definitely seeing more business picking up on the intermodal side of our transport business,” says Lenz. “I think that’s a good sign for our industry overall. I don’t feel it will take a large percentage of business away from our industry, because even when you haul freight by rail, at some point it still has to be taken off the train to get to its final delivery point.”

Intermodal and rail use has helped open the door to increased use of telematics, or remote monitoring, for truck and trailer refrigeration applications, Kiefer says. Carrier Transicold provides refrigeration systems to the rail industry, which for years has used satellite monitoring of refrigerated railcars that run unattended.

Building on its railcar systems, Carrier now has adapted that technology for intermodal truck trailers. Carrier’s Advance microprocessor control and new APX Control System take advantage of the DataTrak capability that allows microprocessor information to be extracted for one-way monitoring or two-way monitoring and control. Data exchange is done via telematic remote monitoring systems, which include cellular, radio and Wi-Fi, as well as satellite.

Telematic tracking of refrigerated units has other benefits. Monitoring via telematics can help document that temperatures inside the trailer were maintained within proper ranges throughout a delivery. Other Carrier applications can record door-opening events via the onboard data logger to track theft and monitor security, and provide feedback on sudden fuel loss that might signal theft. “If equipment problems are identified by the unit’s real-time diagnostic software, dispatchers can determine whether immediate action is warranted and even direct the driver to the nearest Carrier dealer for a coordinated maintenance resolution,” Kiefer says.

The refrigerated trailer business also has seen a trend toward large vans for regional and urban delivery because they’re more fuel-efficient than large trucks. “Driver restrictions aren’t as great for these vehicles because they don’t require special licensing,” Lenz says. “So when you look at the challenges in our industry concerning driver recruitment and retention, the larger vans are a little bit more friendly.”

Thermo King has seen a shift from the demand for fixed-body straight truck products toward those designed for larger vans; that’s why the company has invested in smaller lightweight reefer units than can be mounted on smaller vehicles such as Ford’s compact TransitConnect urban delivery van, which can offer fleets a fuel-efficient final delivery option in tight urban environments.

For years, refrigerated fleets have differentiated themselves with on-time service and product quality. But events such as driver error, running out of fuel or vandalism can cost these fleets dearly, so technology that can help avert a single lost-load claim or late delivery easily can make a fleet more profitable or help it offer a competitive edge. New reefer technologies now give fleets continuous real-time control of sensitive cargo while saving fuel and increasing overall asset and driver productivity.