Volvo’s Olof Persson

Volvo’s Olof PerssonOlof Persson, president of Volvo AB, discussed the company trucking arm’s direction and strategy at the Heavy Duty Manufacturing Association (HDMA) at the 25th Annual Breakfast Briefing at the Mid-America Trucking Show in Louisville, Ky Friday.

Persson says Volvo has invested $1.4 billion in North American manufacturing since 2002, with $250 million invested in support of its truck operations.

Those investments have paid some dividends on the road, as Volvo gained slight share in North America in that time span.

Among the pressures facing the industry, Persson says society will continue to demand increased safety.

“There is also an increased awareness and a desire for the technology that exists, or is already in development,” he says noting this will cause a dramatic shift from passive to active safety systems. “When it comes to traffic safety, the vision of the Volvo group is to have no accidents in Volvo trucks.”

Stresses on environmental goals, especially Greenhouse Gas regulations, will continue to drive vehicle complexities, Persson adds.

“We continue to believe DME shows tremendous promise,” he says of an option to diesel fuel with which Volvo has already heavily experimented. “I think DME could really be a game-changer.”

As Volvo continues to search and test ways to maximize fuel economy, don’t expect them to look heavily (if at all) toward glider kits. Persson says while glider kits might serve a legitimate need, “in worst cases, they are allowing older dirtier engines to be put in a new truck. I find it curious that this practice is so widely permitted. This is not a practice that Volvo will be evolving.”

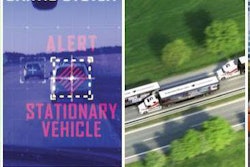

Rather, Volvo will throw its energy behind powertrain integration, which Persson says is the most efficient way to manage and maximize efficiencies. Among the ways Volvo plans to maximize efficiencies is through connectivity, which Persson says “will deliver uptime breakthroughs. We are rapidly approaching a point where there is not truck that will be off-line,” he adds.

“These system have allowed us to be increasingly proactive in making changes to the vehicle wirelessly,” Persson says. “We’re working toward wireless workshops … where in some cases they are being repaired remotely.”