Hendrickson’s Optimaax is designed to lift the forward tandem axle automatically when loads are light and shift the unsprung weight to the rear drive axle without overloading it.

Hendrickson’s Optimaax is designed to lift the forward tandem axle automatically when loads are light and shift the unsprung weight to the rear drive axle without overloading it.For a long time, 6×4 drive axles on heavy-duty commercial vehicles were the default spec for fleets regardless of application. The thinking was straightforward: Torque was king, and getting a load rolling as quickly as possible was a primary concern. Diesel fuel wasn’t as expensive, and there was little reason to consider any alternative axle options.

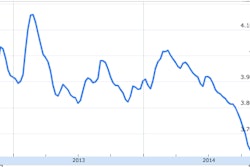

Today, fuel economy is a primary concern for fleets with razor-thin margins and competitors breathing down their necks. To help alleviate those concerns, more fleets are turning to 6×2 tandem axles, which have made significant inroads for a variety of reasons, including higher-horsepower engines and more efficient drivetrains.

According to a recent study by the North American Council for Freight Efficiency, a 6×2 tandem axle will provide an average 2.5 percent improvement in fuel economy. As with many new technologies, however, several disadvantages offset the benefits derived from running 6×2 tandems as a fuel-saving spec.

| [gttable type=table-hover” cols=””]“There is more usable power to move the vehicle.” – Brad Williamson, marketing communications manager, Detroit [/gttable] |

“The benefits are both fuel economy and weight reduction,” says Brad Williamson, marketing communications manager for Detroit. In many applications, 6x2s are available with faster axle ratios, which deliver even greater fuel economy, Williamson says.

In terms of how they work with a truck’s powertrain, 6×2 axles aren’t much different from a standard 6×4 configuration; the engine and transmission still deliver power to the driveline and then to the axle and tires. Williamson says a 6×2 axle’s main benefit is the reduction of moving and interacting parts, creating less friction loss and therefore reducing rolling resistance.

“Reducing the rolling resistance improves fuel economy by allowing the energy created by the powertrain to transfer to the ground with fewer losses so that there is more usable power to move the vehicle,” he says.

Dave McCleave, director of marketing for Hendrickson, acknowledges that removing a drive tandem axle reduces weight and results in a 3 percent fuel economy improvement due to the elimination of parasitic losses. “However, the 6×2 application is limited by traction concerns, particularly when bobtailing or partially loaded,” McCleave says.

To address these limitations, Hendrickson designed its Optimaax liftable forward tandem axle to lift the forward axle automatically when loads are light and to shift the unsprung weight to the rear drive axle without overloading it to provide additional traction and enable 6×2 applications.

“Additionally, an empty or lightly loaded tractor has the ability to operate as a 4×2,” McCleave says. This configuration eliminates the forward drive axle’s rolling resistance, as well as thrust and tandem scrub, allowing fleets to adjust their axle settings to meet the application at hand, he says.

In the lifted position, a minimum 2 percent fuel economy improvement is gained, resulting in more than a 5 percent improvement compared to 6×4 configurations, McCleave says.

“When rolling resistance, thrust and tandem scrub is removed by having the forward tandem axle in the lifted position when the capacity is not required, powertrain components are not working as hard,” he says. “This plays a part in the overall fuel efficiency gains for the vehicle.”

Optimaax’s flexibility is suited for bulk and other variable-load haulers, including large deadhead runs, McCleave says.