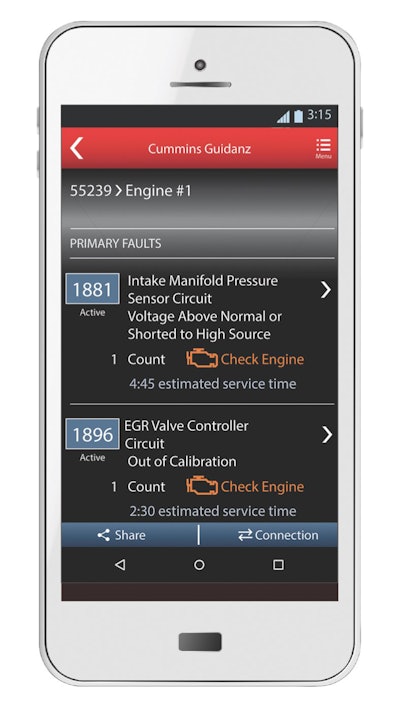

The Cummins Guidanz app, available this April, provides engine fault code information and other key diagnostic data on iOS and Android mobile devices.

The Cummins Guidanz app, available this April, provides engine fault code information and other key diagnostic data on iOS and Android mobile devices.During a press conference at the 2017 Technology & Maintenance Council’s Annual Meeting and Transportation Technology Exhibition in Nashville, Cummins announced several new features in its effort to optimize maintenance procedures and lower cost of ownership for its fleet customers.

Cummins OilGuard, first mentioned at the launch of the company’s new X15 heavy-duty engine last summer, is now available. The engine oil analysis program is offered free of charge for customers that sign up and receive oil sample kits to send back to Cummins’ laboratory for analysis. Cummins personnel analyze the oil and make recommendations on oil drain intervals, which Cummins says can be up to 80,000 miles depending on the application.

“Fleets with X15 engines are able to get tailored information to determine the best oil drain interval for the operation they run,” said Mark Ulrich, director of customer support. “With oil changes routinely costing $350 or more for the oil, oil filter, labor and disposal costs – and a typical over-the-road trucker performing two to three oil changes per year – we see the potential to significantly reduce costs and downtime, with some customers needing an oil change only once a year.”

Cummins also announced a partnership with Valvoline for the Valvoline Premium Blue program that allows oil drain intervals up to 60,000 miles for X15 engines, 10,000 miles more than other API CK-4 oils.

Building on the company’s Connected Diagnostics platform, Cummins introduced its Connected Advisor, a program that provides an additional level of support in interpreting engine issues and improving operational efficiency with time-to-service recommendations for both critical and noncritical issues, making it easier for fleet managers to make service decisions about the vehicles in their fleets.

“Time-based recommendations allow customers to make more educated decisions about operations and maintenance,” said Chad Pruitt, executive director, Cummins Care.

In addition, Cummins introduced Connected Software Updates, allowing over-the-air programming of X15 engines to improve fleet management and enhance engine performance.

“In eliminating the need to schedule shop visits for calibrations, they not only avoid technician labor costs, but they no longer need to spend days out of commission waiting to upgrade their vehicles,” said Lori Cobb, vice president of connected solutions. “In as little as five minutes of downtime, the software update is installed, and the vehicle can get back on the road.”

Cummins says it is working to allow OTA programming of previous-generation engines with onboard memory. Both Connected Advisor and Connected Software Updates will be available in later this year.

Cummins has also developed Cummins Guidanz, a mobile app that leverages cloud computing technology and allows customers with in-house service centers to read fault codes and other key engine information for 2007 and newer engines. The solution uses the company’s nine-pin Inline mini Bluetooth adapter that plugs into the SAE J1939 interface and provides critical information for operations managers or service providers.

The Guidanz app, which also links customers to the closest certified repair location, will be available for iOS and Android mobile devices in April 2017.