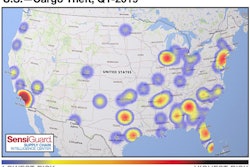

Incidents of cargo theft across the U.S. fell 19 percent last year versus 2017 and there was a 2 percent decrease in the value of theft, according to a report from cargo theft recording firm SensiGuard.

The firm recorded 592 cargo thefts in the U.S. in 2018 worth an average of $142,342. The fourth-quarter holiday season was the most active with 171 thefts, compared to 159 thefts in the third quarter, 145 in the second and 117 in the first.

“There’s three principals of cargo security,” says EPIC Insurance Brokers and Consultants Vice President of Transportation & Logistics Risk Control Michael Nischan. “There’s secure the truck, secure the facility and the less who know the better.”

And despite all that money sitting on the dock or on a trailer, and the relative ease in which security measures can be implemented, Nischan says many carriers have a lackadaisical approach to security.

“The biggest problem I see with the cargo and equipment theft problem is sort of like personal health,” he says. “It’s that companies don’t want to deal with it. They’re either turning a blind eye to the situation, they think they’re immune for whatever reason, or they just don’t want to invest the time, the energy or the financial investment to combat the problem.”

Asset security strategies can vary and according to Nischan there is no one-size-fits all solution, but the first step in addressing needs, he says, is evaluating current practices.

The logical place to start is how people access the property and cargo.

Security gates and door latches, Nischan says, are often secured using inadequate, inexpensive, consumer-grade locks.

“You’re wasting your money,” Nischan says. “[Fleets] think they can go do down to Home Depot or Lowe’s or any of these hardware stores and just go down to the locks section and buy any lock – a Masterlock – and the problem is solved.”

“A lock only keeps an honest man honest,” adds Gerry Mead, Phillips Industries executive director of innovations.

As simple as they sound, technology has carried locking capabilities a long way. Jacob Peterson, East Coast sales for National Fleet Products, says his company’s app-based UFO Cloud Lock allows fleet managers to monitor and record who opens and closes a vehicle door, and when and where it takes place.

The lock can also be engaged or unlocked remotely and from the back-end of the platform, managers can text message digital keys for employees who may need temporary or one-off access to the box.

“From the fleet perspective, they’re looking for force compliance,” Peterson says, noting the UFO Cloud Lock relocks automatically when the door is closed. “The traditional puck lock doesn’t get used. It is an optional system.”

Using the system’s geofencing capabilities, Peterson says a vehicle’s cargo area can be rendered inaccessible between points. Access can be granted exclusively to cargo recipients or at designated destination points along a route.

But a high-quality lock will only deter theft to a degree and if it fails a thief now has access to the trailer and what’s inside, making security at the loading dock important.

“When a trailer is positioned at the loading dock, the trailer becomes an extension of the facility,” says Rite-Hite Director of Marketing Ken Bowman. “Cargo theft doesn’t just happen on the road or at truck stops. It can happen anywhere.”

Rite-Hite’s Dok-Lok secures the trailer to the dock, preventing the trailer from moving during on- and off-loading, but also serving as a visual deterrent to prevent theft. By immobilizing the asset, Bowman says Dok-Lok lessens the likelihood that it will be taken.

Additionally, Dok-Lok can be integrated into the facility’s existing alarm system and programmed to set off an alarm if the system is tampered with, just as the alarm would sound if a would-be thief had kicking in the front door.

In instances where trailers aren’t dropped at the dock, devices like Phillips Connected Technology’s Trailer Lock-Down can lock the air brakes when power is disconnected from the tractor. To release the brakes and pull a trailer, Mead says a PIN code from dispatch has to be keyed in from a smart device to the Phillips Connect Technologies’ control box.

While less technologically sophisticated, king pin locks are inexpensive yet effective tools in that they prevent unauthorized coupling.

Security cameras – what Nischan calls “one of the simplest tools” in which companies can invest – aren’t much of a deterrent, but are helpful after the fact in the investigation.

“We live in a world now that surveillance cameras are just everywhere,” he says. “This is very simple, very accessible tool. [Cameras] maybe don’t deter the crime, but we can at least get useful information, suspect description, vehicle description … something that’s of use in investigation later to secure prosecution and conviction.”

If a thief has beaten perimeter security and the security on the loading dock, carriers have to start thinking about asset recovery because that unit – and its load – is as good as gone.

Telematic-enabled security devices aid with recovery by reporting trailer location back to the carrier. They are critical tracking aids following a theft, but Mead says they’re only helpful if they’re not first discovered by the thieves.

“I’ve been involved in several cargo theft issues where we pinged the trailer and it got us right to our sensor because they simply removed it and threw it in a ditch while our trailer was moving down the road somewhere else,” Mead says. “A thief will find a way to defeat any device, so you have to think outside a thief’s realm and one of the best ways to defeat them is going covert and hiding devices that they can’t easily get to.”

“Covert tracking technology, that is a great tool,” Nischan adds.

A good base-layer of covert cargo security, Mead says, is a GPS-enabled sensor with accelerometer that can easily be hidden away in the wiring harness.

“You’ve got to have a hidden-away GPS unit, a covert one” he says. “You can have your regular one on the side but you’ve got to have something that’s hard for them to get to and isn’t easy to defeat.”

The GPS capability can help with recovery and the accelerometer triggers an alert when it senses the trailer is moving, allowing for the discovery of the theft earlier.

“When you think about telemetry-based [security sensors], they set up geofences. Movement inside the geofence is alright but any movement outside the geofence triggers an event, but really you want [notification] some kind of movement period,” Mead says. “When you’re talking about a $5-$6 a month pill to swallow [in monitoring fees] but you get base location on your units and you get to know when they move, that’s your first level [of security]. That’s the first part of security is knowing where your asset is and then knowing if it’s doing what it’s supposed to second.”

Full truckload thefts accounted for the most thefts by event type last year at 74 percent of all cargo thefts, according to SensiGuard.

“Lose one trailer and you pay for a lot of those devices,” Mead adds, noting monitoring fees can vary to upwards of $18 per asset per month for more all-encompassing packages.

For the first time in a decade, electronics were the most-stolen product type throughout last year, accounting for 20 percent of all thefts. Electronics thefts rose 33 percent from 2017, overtaking food and drinks and home and garden products for the top spot.

Food and beverage products – which, on average account for 24 percent of incidents – are targeted because of their low price points, they are hard to trace (lack of barcodes and RFID tags) and the goods/evidence are usually consumed quickly.

Home and garden products, which were the most-stolen items in 2017, ranked second in 2018 with 16 percent of total thefts.

Being proactive in monitoring theft-patterns and continually evaluating internal defense programs, Nischan says, is another important part of an anti-theft initiative.

“If you think your company is all set, that you’ve done everything to address the risk [of theft], be aware that may not be true in three months,” he says. “That may be something that evolves seasonally or as the market changes, but it’s good to regularly review and test your programs to identify areas for improvement.”

Being seen as an easy target can have implications other than simply the loss of assets and loads. While carriers with a solid anti-theft program in place may not realize a reduction in insurance premiums, Nischan says a reduction in the number of incidents should lead to overall savings.

“Therefore your premiums will improve over the long term,” he says. “However, there are insurance companies that from time to time will recognize and/or partner with a vendor and they will offer preferred pricing for those technologies.”

Inadequate security measures – like using ties or seals when locks would be more appropriate, for example – also exposes the carrier to greater potential liability.

“If I’m the guy who’s supposed to be getting the [load], I’m going to sue the pants off that carrier and saying their security methods were negligent,” says Interstate Trucker President Brad Klepper. “They’re clearly below the standard of care for the industry. Using zip ties to secure your trailer ain’t getting it done. So you’re negligent in doing that and you’re liable to me.”

An anti-theft defense is a strategy, and Nischan says the key to deploying an effective strategy is setting clear goals.

“It’s not necessary to turn your facility into Fort Knox with night vision and barriers and guards and IDs and policies and procedures and all these extravagant things at once. That’s not now it works,” he says. “If you go through an assessment process and begin studying what you’re doing, how you’re doing it, what your risk is, what your commodity is and then utilizing some simple tools to begin managing your processes, you can build a foundation from there. But you have to start somewhere.”