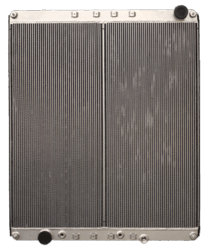

Kustom Cooling’s all-aluminum Freightliner Cascadia Radiator uses the company’s proprietary “Wavy Fin” design set in a bar-and-plate configuration for added performance, durability and reliability. The design helps prevent clogging of the cores due to road debris since there are no catch points; the fin is smooth from front to back and less susceptible to bending or lying over, and since there is more contact area of the fin to the plate, the overall strength of the core is increased as well as providing a more uniform control of thermal expansion as the coolant temperature heats up.

Welding the aluminum tanks and core together facilitates a burst pressure of 100 psi, while a tube wall thickness of 0.06 inch adds more material to help reduce tube failure due to vibration and road debris. The aluminum transmission oil cooler and aluminum top and bottom tanks allow brazed aluminum threaded inserts to be welded directly into the tank. For the side channel, a flat bar is tied into the upper and lower tanks along the continuous weld around the core-to-tank connection. A piece of ¼-inch-thick neoprene is secured inside the radiator channels to help reduce road vibration.