Trucking news and briefs for Friday, Sept. 3, 2021:

Drivewyze rolling out automated electronic roadside inspections

Weigh station bypass service Drivewyze this week demonstrated automated electronic roadside inspections and how they can save time and money, while also improving highway safety.

The demonstration took place at the CVSA conference in Wilmington, Delaware, in front of convention attendees that included state law enforcement and fleets from throughout the country.

Trucks and drivers, provided by Western Express and Schneider and equipped with Drivewyze PreClear, were on hand to illustrate how e-Inspections work. A simulated inspection site showed how time-consuming elements of traditional manual inspections, such as searching multiple systems to verify carrier, vehicle and driver credentials and more, can be automated to save significant time for both inspectors and drivers.

Using e-Inspections, an officer viewed vehicle, carrier and driver-level information transferred electronically while the vehicle was still in motion. The inspection system further streamlined the inspection process by screening carrier, vehicle and driver data automatically against multiple systems – all at once – for compliance issues, allowing the officer the freedom to validate data or focus on non-electronic elements of an inspection.

In addition, the officer had their inspection form automatically pre-filled at the start of their inspection, avoiding time-consuming and error-prone manual data entry. When the officer was satisfied, the inspection was completed at the touch of a button, saving significant time, and improving the accuracy of the inspection.

“What the demonstration showed was not the future – it’s showing the here and now, and how Drivewyze and our partners are re-creating traditional inspections,” said Brian Mofford, Drivewyze’s vice president of government experience. “It takes the leadership of our public agency partners, and the capabilities of our connected truck technologies to create a new paradigm in delivering highway safety. There are too few inspectors for enforcement to operate effectively against an ever-increasing number of trucks on the road. e-Inspections are a force multiplier that increases the reach of our agency partners without impacting the movement of our economy’s freight.”

Mofford added that e-Inspections could cut a “clean” inspection from 30 minutes or more down to just a few minutes without impacting the effectiveness of the inspection.

“It benefits carriers and drivers who can log more drive time, plus it allows inspection officers to screen more vehicles in a timely fashion,” he said.

According to Mofford, five states – Maine, Maryland, New Hampshire, Virginia and Michigan – are rolling out e-Inspections, through Drivewyze ELD partners Geotab, Platform Science and now Trimble – which was announced at the CVSA convention. Additional ELD partners offering e-Inspections will be announced soon, as will additional state partners.

Mofford added that e-Inspections will allow for more inspections to be conducted, which will be of help for carriers and their CSA scores.

Nikola partners with Bosch for fuel-cell development

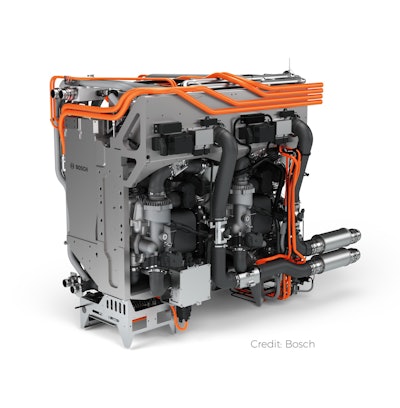

Through the partnership, Bosch will supply both fully assembled fuel-cell power modules as well as major components to Nikola.Bosch

Through the partnership, Bosch will supply both fully assembled fuel-cell power modules as well as major components to Nikola.Bosch

The agreements will allow the adaptation of the fuel-cell power modules for the Nikola Tre and Nikola Two fuel-cell applications. Under the agreements, Bosch will supply both fully assembled fuel-cell power modules as well as major components to Nikola, including the fuel-cell stack, for Nikola to assemble at its manufacturing facility in Coolidge. The companies will work together for sourcing of remaining components for the assemblies.

Nikola and Bosch have defined together a scalable and modular approach for the Nikola Tre and Two truck applications based upon use of multiple fuel-cell power modules utilizing the Bosch heavy-duty commercial vehicle fuel-cell stack. The fuel-cell power modules are expected to launch in 2023, with the first application being the Class 8 regional-haul Nikola Tre FCEV.

Nikola anticipates that the overall vehicle design will result in a range of up to approximately 500 miles. Nikola plans to further expand capacity for use in the Class 8 long-haul Nikola Two FCEV with an anticipated range of up to approximately 900 miles.

The vehicles are planned to utilize common fuel-cell power modules in 200 kW and 300 kW configurations. The fuel-cell power modules and components are being designed and validated for the demands of commercial vehicle power. The Nikola Tre FCEV will also be launched in the EU, utilizing the same fuel-cell power modules supporting vehicle manufacturing planned at Nikola’s joint venture with IVECO in Ulm, Germany.

Bison adds battery-electric trucks to fleet

Bison Transport (CCJ Top 250, No. 52) is now operating a full battery-electric Class 8 truck in its cross-border operation as part of a partnership with Freightliner.

In the partnership, Bison will run two full BEVs exclusively between Delta, British Columbia, and Washington state.

“This is an important step towards zero emissions in the transportation sector and we are excited to be able to facilitate this project with our partner Freightliner,” says Mike Gomes, Vice President, Maintenance at Bison Transport. “It is not as simple as a replacing a current tractor with a BEV, infrastructure and network operational considerations exist. We plan on testing the limits of the technology, understanding how to manage when there are disruptions, either operationally over-the-road or to the supply chain, and how we work around these opportunities.”