Recently I had an opportunity to lead a NACFE effort that brought back fond memories of when I led customer engineering and the pilot center at Cummins. In those days, our team did a lot of work to improve fuel economy.

My recent NACFE assignment was to update a TMC recommended practice (RP) regarding driver behavior that influences fuel economy (RP 1114). This experience provided me the opportunity to work with industry experts from the OEMs, Tier I suppliers, fleets, and to my surprise, safety/health experts.

A win-win outcome can be achieved if fleets follow this procedure. The financial bottom line and sustainability goals can be improved. Both the carbon footprint (e.g greenhouse gases) and particutlate emissons (CO2, NOx, and PM) can be reduced. All of this comes with very little investment. Also, by following this procedure, one of NACFE’s goals — to burn less diesel through efficiency and is discussed in the Messy Middle report — is met.

We often think that efficiency improvement comes from the OEM and Tier I suppliers. Collectively, they spend billions of dollars each year in research and engineering and CapEx, improving the efficiency of vehicles. The most common and influential areas of improvement are tractor aerodynamics, trailer aerodynamics, the powertrain, tires, wheels, and idle reduction features.

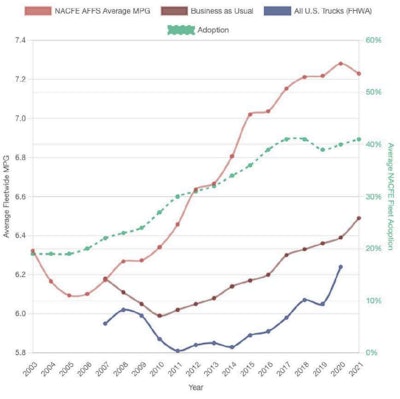

All of these things are critical, and our efforts in the trucking industry are paying off. NACFE runs a Fleet Fuel Study, and it has shown year-over-year improvement in fleet’s fuel economy. The figure below is from the NACFE 2022 report. Notice the upward MPG trend over the last 10-plus years. NACFE will soon release the 2024 report, so stay tuned for some exciting results.

While the work that the OEMs do is critical, one of the most influential factors on fuel economy is the driver. Studies have shown that the driver can influence fuel economy by as much as 30%. If a fleet can raise the bar of the lowest performing drivers, they can make significant improvements to their fleet average. Savings for larger fleets can amount to millions of dollars in fuel per year while also improving sustainability.

Here are the key things fleets and drivers can do to achieve these results:

Proper vehicle spec’ing

Work with the OEM to understand all of the electronic, aerodynamic, tire and trailer gap features. Make sure all electronic parameters are properly configured.

Electronic and monitoring features

Set cruise control, idle reduction, progressive shift, GPS/navigation features properly. Work with the OEM/dealer to optimize this. Don’t override predictive cruise features. Also, one problem that I experienced in my early days that continues to haunt fleets is that the parameters are not locked. Make sure that with every software update the parameters do not reset. As for navigation features, use them to take the most efficient route. Finally, use monitoring features to provide instantaneous feedback to the driver.

Drive with fuel economy in mind

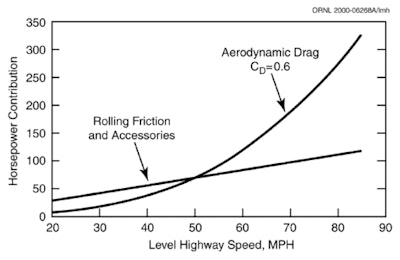

Limit “jack rabbit starts.” Drivers should try to anticipate when they will need to slow down then coast instead of braking. Maintain proper following distances. By increasing following distance the driver can reduce the need for rapid decelerations and accelerations. Anticipate traffic lights to avoid rapid braking. Use adaptive cruise control for appropriate spacing. Run in top gear as much as possible. Limit maximum vehicle speed. The graph below illustrates the strong impact of running at lower vehicle speeds. The graph shows that approximately an extra 75 HP is needed just to overcome the aerodynamic drag forces when running at 60 MPH vs 70 MPH. This difference in horsepower translates directly to an MPG improvement and, as the curve illustrates, it is quite steep in this range of vehicle speed. Keep in mind that this DOE graph from 2000 is a bit dated reflecting less aerodynamic pre-2010 vehicles. The crossing point in the curves between rolling resistance and aerodynamic drag with more modern very aerodynamic tractors and trailers has shifted farther to the right to between 60 and 70 MPH.

Idle and auxiliary devices

There are studies that show about 1 gallon of fuel per hour is consumed when idling. If an engine idles three hours per day, this translates to about 1000 gallons of fuel wasted annually per vehicle. While one might not think the engine is idling that much, it adds up quickly when considering stop-and-go and overnight idling. Some of the things that can be done are to ensure the ECM limits idle time and for the driver to limit the use of accessories. Just like at home, does the TV need to remain on in the sleeper cab if no one is watching it? There are different APU technologies, so give serious thought to the correct technology and product.

Vehicle walk-around

Ensure the tires are properly inflated. Ensure proper trailer gap, aerodynamic deflectors, etc. are installed prior to departure.

Health and safety

As stated in my opening comments, I did not initially think that health and safety would factor into a fuel economy discussion as I led the TMC initiative. However, it does have an impact. We are all at our best when we feel good. When we are sleepy, depressed, stressed, etc., we make mistakes. Our minds are distracted. We take the wrong turn or route, and we don’t think about all of the best-driving habits. Fleets can educate drivers on getting proper sleep, nutrition, stress management, etc.

Training, incentives, and other TMC sources

TMC Recommended Practices also can assist fleet managers in improving driver fuel economy performance, including: RP 1105A, Idling Limiting Systems, RP 1107, Spec'ing Drivetrains. RP 1111B, Relationships Between Truck Components and Fuel Economy. RP 1113, Guidelines for Driver Incentive Programs

Being in industry for 40 years, I always have been excited about launching new technology and products. These products lower emissions and improve fuel economy. I was thrilled to be a part of large teams and multi-million dollar projects. All of this work gave me a sense of purpose. However, similar to many other lessons in life, simple ideas can be very effective. They often yield equally important and influential leverage.

Fleets can take these low cost steps by properly spec’ing their vehicle, training their drivers, and incentivizing their drivers to run the vehicle in the most efficient way. And that will be good for all of us.