As of 11 a.m. on Feb. 1, 326 trucks had exited the east gate of the SSA Marine Oakland International Container Terminal in California, marking an average total turn time of one hour and 12 minutes. That’s according to the Port of Oakland’s Freight Intelligent Transportation System (FITS), launched a month ago, that aims to improve operations across the port for its many stakeholders, including truck drivers.

The FITS solution includes the new Oakland Portal that provides improved efficiency and visibility into the movement of goods through real-time insight into vessel operations and statuses, regional traffic conditions, rail crossing access, turn time data and more.

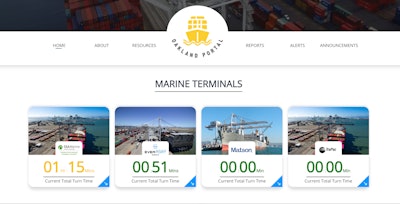

The Oakland Portal’s website and app displays a snapshot of the total turn time for each of the four terminals on the main page with the option to click on each for additional details like specific gate information. Each truck that enters a terminal is required to have a Radio Frequency Identification (RFID) tag that is read at the entrance and exit security booths beginning at 0600 every day. The time it takes each truck to get from the security entrance to security exit is the truck turn time.

Pia Franzese, senior maritime projects administrator at the Port of Oakland, said turn times is just one of the many pieces of information the new portal offers, and this level of visibility all in one place will have a positive impact on the efficiency and collaboration of port activities, creating a domino effect for stakeholders, improving their decision-making abilities for their individual needs.

“The Port of Oakland (Port) launched the FITS portal to help solve port challenges and provide a centralized source for reliable, real-time information. Before FITS, we had increasingly heard feedback from Port stakeholders that they had to go to multiple sites to get information for Port operations, creating a cumbersome process with conflicting information. Multiple platforms led to inefficiencies and confusion for users,” Franzese said. “The intent of the Oakland Portal is to have a one-stop platform where port stakeholders can go to find secure information relevant to them, such as information about terminals and turn times. The portal serves as the foundation for the port’s data technology, which will continue to expand. We plan to continuously add to this portal, such as a smart parking system and container data, among many others.”

FITS is comprised of various IT hardware and software infrastructure elements, including upgrades to the port’s fiber, installing changeable message signs to the roadway, a buildout of an emergency operations center, a weigh-in-motion scale so truckers can weigh themselves on the way out and smart cameras that collect metrics on vehicle speeds, traffic patterns and pedestrian counts that the port reports internally and externally to stakeholders. Additional intelligence is added to these devices, such as video analytics, Franzese said, to determine how long it takes a truck driver to wait at a terminal and then get through a terminal. The information comes together in the Oakland Portal to improve situational awareness and management for users, which improves mobility and safety, she said. Another part of FITS included the development of two applications: the Oakland Portal and the Smart Parking System (SPS). The SPS, launching later this year, will allow stakeholders to make parking reservations.

“Together, all of these elements work to improve operational efficiencies and provide real-time, reliable information to port stakeholders, such as truckers, terminal operators, wharfingers and ocean carriers, to enable better-informed, data-driven decisions,” Franzese said.

In additional to improving operational efficiency, these elements will impact sustainability, she added.

“For example, the Oakland Portal and other technologies within the FITS platform provide visibility into traffic congestion, informing the trucking community about the best times to arrive at the port,” she said. “This information reduces wait times and congestion, which contributes to less emissions. Overall, the more efficient the port is with goods movement and traffic circulation, the less pollution will result, creating a more sustainable port community.”

That port community, Franzese said, has been key to implementing and improving the new system.

While still in its early days, she said the Oakland Portal is running smoothly and has secured positive feedback from users as well as feedback on additional information users would like to see, “which is a good sign since engagement shows people are using the tool and want to see it expand to more fully meet their needs.”

The port designed the system and portal based on its specific needs, and Franzese said the port would advise other ports developing similar tools to do the same.

“We would recommend other ports think about the idea of an integrated data environment by first thinking of users, personas and use cases to make sure whatever is developed has the users’ experience at the forefront of every step,” she said. “In addition, we recommend having a systems integration perspective and a port-owned central place, such as a data hub where the data comes to, and a central place, such as a website and app, where users can consume the information. It is so easy to have disparate systems; however, the power of data is having different datasets layered on top of each other.”

Franzese said the Port of Oakland’s data previously came from third-party sources, but FITS enables data to come directly from the port’s equipment, providing greater control and confidence that the information is accurate.

One of the greatest benefits that FITS allows, she said, is the ability to proactively address any issues via predictive modeling. The data from the system allows the port to identify pinch points in the terminal or specific periods of the day where there is increased congestion or bottlenecks in the movement of containers, for example. It also helps the port understand when to schedule maintenance or other activities to not adversely affect port users.

Parsons Corporation, which has worked with the port, Alameda County Transportation Commission, the City of Oakland, the California Department of Transportation and subcontractors over the last four years to develop FITS, will leverage artificial intelligence with video and data analytics to predict freight wait times and develop predictive models around road blockages at train crossings. The data collected will also be used to create customized dashboards for custom border protection and port shipment tracking.

Parsons’ advanced traffic management software solution, iNET, was integrated with an enhanced version of the SecūrSpace smart parking system and a new custom GoPort website and mobile application for iOS and Android, to create FITS. FITS’ Oakland Portal is powered by the Advent eModal platform.