Peterbilt's Model 567 is a tool as familiar on a job site as a DeWalt cordless drill, and soon those two things will have one more thing in common.

Peterbilt is going after the work truck segment with its newest battery electric model, keeping a still-emerging zero emissions technology in the space where it's found the most success to date: short hauls that return to base without needing to find near-non-existent public charging.

The new Model 567EV is designed for vocational applications like dump trucks, utility trucks and equipment haulers and is the first BEV to come to the vocational market – a segment where Peterbilt holds a more than 21% share.

Peterbilt Assistant General Manager of Sales and Marketing Erik Johnson said the zero emissions vocational segment was ripe for Peterbilt's taking, and the company has already had interest from customers in utility and municipal, dump fleets, and refuse fleets that already have Model 520EVs and are looking to potentially add an electric roll on/roll off.

"Those lighter vocational (fleets)," he said, "with the ePTO... they're able to run a bucket and all the way up to a dump body."

The body uses the batteries onboard the truck via the ePTO; either 25 kW or a 150 kW.

"You can see PTO energy usage in the digital driver display, so it's well integrated," said Patrick Wallace, electric vehicle marketing manager for Peterbilt.

Vocational applications, where range is limited by the nature of the business (generally 250 miles and less) and often include long periods of idle to drive accessories, are where electrification can shine brightest.

"There's some applications that the battery electric truck excels and does a better job than diesel trucks," said Jake White, Peterbilt's director of product marketing. "Short runs, some of those are more difficult for the after-treatment systems, so we really target a lot of those kinds of applications where there is a genuine TCO benefit. A lot of times electricity is more cost effective than diesel. In fact, in almost all cases. The truck costs a little bit more but the fuel is less expensive. Those kind of high mileage, short run, fixed infrastructure applications... we're talking to a lot of fleets that run in those that are looking at that from a dollars and cents perspective and pencils out."

While it might make a lot of sense for a public utility to power its service trucks with the same power they generate and sell, Peterbilt Director of Product Planning and Strategy Mitesh Naik said vocational customers face the same zero-emission pressures as their on-highway counterparts: regulations and Environmental, Social, and Governance (ESG).

"Hypothetically, if I'm a concrete mixer operation somewhere in California, then I'm very interested in a 567 battery electric," he said. "In essence, it's the perfect use case. The trucks come home every night and therefore they get charged up and they're sent out again."

The electric 567 is available in wheelbase of 190 inches or longer and applications up to 82,000 lbs. gross combined.

The 567EV is available with a lift axle and in set-forward and set-back configuration and, across the lot, it looks like any other 567. Upon closer inspection you'll notice a blue-accented crown and grille, as well as EV-exclusive panels on the side of the hood that replace now-unnecessary air vents. The 567EV features the same Platinum Ionic Gray interior as its fossil fuel sibling.

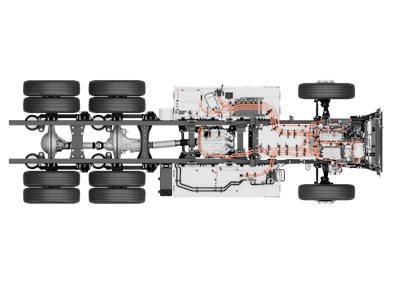

All new Paccar ePowertrain

Midship-mounted eMotor with dual electric motors and integrated 3-speed transmission to deliver seamless shifting with no torque interruption.

Midship-mounted eMotor with dual electric motors and integrated 3-speed transmission to deliver seamless shifting with no torque interruption.

The new ePowertrain is the fruit of more than five years of development and testing and its flexible architecture allows for integration with existing suspensions, Johnson said.

The batteries utilize lithium iron phosphate (LFP) chemistry that offer extended battery life and better long-term performance. LFP batteries, Johnson noted, retain 80% of their capacity after 10 years of use – "significantly better than any other chemistries."

Other features of the new powertrain include redesigned electronic accessories and thermal managed batteries for performance in all weather conditions.

"If you have the truck plugged in, you can actually set your departure time," Wallace said. "The truck will wake up about an hour before you're set to depart. It will warm up or cool the batteries, and it will warm up or cool the cab to the last temperature that you set. When you leave, you're ready to go. It's essentially the same as warming up your engine."

The truck is equipped with both AC and DC charging capabilities up to 350 kW – a significant boost from the 150 kW capability of the current generation powertrain.

"If you have the right charger – even with these giant batteries – you can go 0% to 80% (state of charge) in as little as two hours," Wallace said.

A mid-mounted eMotor with dual electric motors and integrated 3-speed transmission delivers shifting with no torque interruption. Multiple power options are available up to 605 horsepower and 1,850 lb.-ft. of torque.

Up to five batteries can be spec'd on the truck, giving it up to 625 usable kWh (up to 250 miles).