A truck’s value isn’t just measured by specs alone, but by the work it can handle.

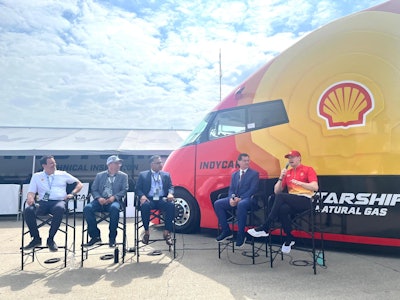

That’s what Shell plans to demonstrate, according to Thomas Mueller, general manager of Commercial Road Transport at Shell. Speaking Thursday at the Indianapolis Motor Speedway in Indiana, Mueller emphasized Shell’s commitment to putting its products to the test.

Shell and IndyCar are strengthening its collaboration by having the Shell Starship 3.0 as the official transporter vehicle for the Pennzoil tech inspection trailer during the 2025 NTT IndyCar Series.

[RELATED: Ride along in Shell's third generation Starship]

Shell has been providing 100% renewable racing fuel for the series since 2023.

“The truck’s not going to be on the track, but it’s going to do the job from track-to-track in between. We like to say it’s a rolling research paper, and we expect that we’re going to learn quite a bit as we put this truck to work,” Mueller said.

“Our organization helped validate the efficiency with measurement devices on the trucks to make sure that whatever Shell was saying, and we were saying, about this truck’s real,” said Mike Roeth, executive director of the North American Council for Freight Efficiency. “So, I’m here to validate that this is probably the most efficient, best natural gas, Class 8 truck in America.”

Shell Starship 3.0 is powered by a Cummins X15N natural gas engine and runs on Shell Rotella natural gas engine oil. It is marked as the first natural gas-powered Class 8 truck operating within a national motorsports fleet in North America. Starting June 1 at the Chevrolet Detroit Grand Prix, the truck will tow IndyCar’s Pennzoil Tech inspection Trailer.

The truck showcases the capabilities of sustainable technologies, such as its lightweight, aerodynamic carbon fiber body, a camera-based system instead of traditional mirrors to improve aerodynamics, and an optimized lightweight chassis.

The next step is integrating the Shell Starship into IndyCar’s operations to examine the impact of advanced technologies in lowering carbon emissions across logistics, Mueller said.

“Hopefully, the idea of putting it to work, we’ll continue to learn even more about not just the bounds of efficiency, but the operational impact. How would it be if this were in your fleet? How do you use it in real life?” said Mueller.

J. Douglas Boles, president of IndyCar and Indianapolis Motor Speedway, said it’s an opportunity to focus on sustainability without impacting the racing product.

“As leaders in this community, we think it’s really important to do that. So, when you take a product like the Starship 3.0, the Cummins engine that’s in it, work with the folks like at NTT Data and Shell, and pull our tech trailer down the road, it’s a great example for us to talk about how we can prove out ways to be sustainable,” he said.

Josef Newgarden, Team Penske driver and two-time winner of the IndyCar series in 2017 and 2019, said the project aligns with the racing facility’s focus on sustainability as they aim to be a zero-waste facility. “In racing, you’re always pushing the limits of speed. We’re trying to put things on the absolute edge, but we’re trying to do it as efficiently as possible,” he said.

Shell Starship 3.0 will transport the Pennzoil tech inspection trailer for the IndyCar 500 Series, which contains the specialized equipment used to inspect all IndyCar teams' cars throughout the rest of the 2025 season.

Shell Starship 3.0 will transport the Pennzoil tech inspection trailer for the IndyCar 500 Series, which contains the specialized equipment used to inspect all IndyCar teams' cars throughout the rest of the 2025 season.

Emissions tracking software

To support comprehensive tracking of its sustainability efforts, Shell announced its adoption of a new AI-powered emissions management platform from software IT service provider, NTT Data.

Kunal Koul, managing director, advisory and digital consulting for NTT, said that sporting events offer a plethora of data. Rather than using estimated data in AI-powered models, Koul said they’re working towards gathering actual data.

Developed with Penske, the platform will be rolled out to a wider user base in the coming weeks. It offers real-time tracking and analysis of emissions from race operations and logistics throughout the season.

The system streamlines carbon accounting (the process of calculating greenhouse gas emissions) by gathering and standardizing diverse data sources, converting them into interactive dashboards and tailored reports. The insights can offer a view of emissions trends and data, helping teams make data-driven decisions.

Building a greener freight network

In demonstration runs with the truck fully loaded and running on renewable natural gas on the West Coast, Shell said the truck achieved a fuel economy of approximately 9 mpg Diesel Gallon Equivalent (DGE) and a range of approximately 890 miles.

Mueller noted that the industry can’t simply wait for a “magic bullet” for the availability of fueling networks and natural gas infrastructure. He emphasized that addressing this challenge requires collective effort from OEMs and customers to governments and regulators alike.

“There’s decent infrastructure for natural gas on the West Coast,” said Mueller. “That’s where we’ve done our proving runs, and the natural gas infrastructure continues to grow. But would make the infrastructure grow is proof of concept.”

Mueller said it is the third Starship project in the U.S., with its first global Starship in China that they partnered with a Chinese OEM for a diesel hybrid truck. While both trucks contain the “family resemblance,” each truck is designed for the roads and needs of the market.