Trust – but verify

Electronic logs are fast replacing paper as the standard for compliance. But do they improve safety?

EDITOR’S NOTE: This is the second of a three-part series on combating driver fatigue. Other stories in this series address technologies for managing driver fatigue and driver-load scheduling.

Customer service was the initial reason Central Refrigerated started using electronic logs. With onboard computers and other technologies, the Salt Lake City-based company could notify customers automatically of load arrivals and departures – but a key component was missing.

Billing a customer for detention charges with errors in driver logs puts a fleet’s credibility at risk, says Allen Lowry, director of safety. “To solidify that process, we wanted to make it easier for drivers to keep track of what time they arrived and departed,” Lowry says.

Almost immediately after deciding to implement electronic logs, Central Refrigerated was audited by the Federal Motor Carrier Safety Administration. The company was not found deficient in any safety category, but it came “pretty close” in the 70-hour workweek rule, Lowry says.

After the audit, the company accelerated its conversion to electronic logs. Lowry credits the technology for reducing drivers’ 70-hour workweek violations by 97 percent and false logs by 100 percent since fall 2008. More importantly, accident severity has dropped sharply during that time – a likely result of reducing driver fatigue, he says.

“After we went to electronic logs, we can guarantee that a driver gets a 10-hour break,” Lowry says. “On paper logs, you don’t know what they’re doing out there.”

In the past few years, hundreds of fleets voluntarily have converted to electronic logs to enforce compliance with hours-of-service regulations. However, the safety benefits of using the technology are not always as clear-cut.

Correlation with safety

Cargo Transporters already was using various safety technologies in its 400-truck fleet before adding electronic logs in winter 2008. Its safety systems included anti-rollover, lane departure warning and collision avoidance technology.

Safety was a major consideration when the Claremont, S.C.-based truckload carrier implemented Qualcomm’s Hours of Service (QHOS) application for its MCP100 in-cab computing platform. Cargo Transporters rolled out QHOS across its fleet within two months.

When using paper logs, compliance always had been a gray area. As part of the dispatch process, drivers had to input their available hours manually into the Qualcomm system. Dispatchers would use this information for making load assignments.

“We found out that drivers manipulated numbers to gain better dispatches,” says Dennis Dillinger, Cargo Transporters president. “We were always at their mercy.”

To solve the problem, management first tried auditing drivers’ hours by using the number of miles traveled since the last dispatch. However, this method proved unfair for some drivers who legitimately could travel more miles in a day than expected.

“There were not a lot of good systems in place,” Dillinger says. “We were doing a lot of things right, but we had a component here or there that was wrong.”

With paper logs, the company also had additional exposure in accident claims. Satellite tracking captured when drivers started their 14-hour workday but did not show total time spent driving. In the event of an accident, the company lacked the means to determine HOS compliance accurately.

“As much as you want someone to run legal, you don’t know if he has driven more than 11 hours,” Dillinger says. “We never wanted anyone to falsify their logs, but we were smart enough to know it was happening.”

Since implementing QHOS in 2008, Cargo Transporters has not seen a significant decrease in its number of incidents and accidents because they already were low, Dillinger says. However, the cost of accidents and the number of open claims has decreased significantly.

“We’ve got a much safer driver today than what we had,” he says. Safety improvements are the result of more than just electronic logs, but the technology is “the final piece that helps us out.”

No more excuses

Southeastern Freight Lines (SEFL) installed Xata in-cab computers about two years ago. Six months later, the Lexington, S.C.-based less-than-truckload carrier added electronic logs for its line-haul operations. In all, SEFL has about 1,100 vehicles equipped with an electronic logs application from Innovative Software Engineering (ISE).

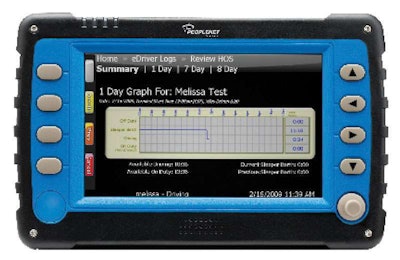

By using PeopleNet’s eDriver Logs application, drivers can access current hours-of-service status, such as their violations and available hours.

By using PeopleNet’s eDriver Logs application, drivers can access current hours-of-service status, such as their violations and available hours.“We trust our people, but we also believe in verification,” says Braxton Vick, senior vice president of corporate planning and development.

Before using electronic logs, SEFL was using satellite tracking data to calculate drivers’ total run time and extrapolate their available hours. With electronic logs, the company now has exact information for more accurate load planning and forecasting tools.

Drivers also appreciate the ease and accuracy of electronic logs, Vick says. Before, drivers often would complete paper logbooks at the end of trips and forget to include some details, such as the location of each stop and the time spent there. The company had no visibility to these errors until a week later when it converted paper logs to a digital format for auditing. Drivers then would have to correct and resubmit logs – long after the fact.

One of the intangible safety benefits of using electronic logs is simplifying communications with drivers. With electronic logs, drivers’ and fleet managers’ responsibilities for HOS compliance are “black and white,” says Raul Tamez, senior vice president of traffic for Alamo Cement, a San Antonio-based transporter of bulk products such as cement, sand and gravel.

“We never wanted anyone to falsify their logs, but we were smart enough to know it was happening.”

The company, which hauls throughout Texas with a fleet of about 200 owner-operators, recently starting using Teletrac’s Fleet Director system with the Hours of Service module. Before using electronic logs, Alamo Cement rarely had incidents where drivers would approach the end of their legal driving limit, Tamez says.

With the in-cab Teletrac system, drivers receive a warning 30 minutes before running out of hours, and fleet managers receive a 45-minute warning through the Web-based Fleet Director system. Instant visibility to driver hours and the advance warnings help ensure compliance and alleviate driver stress and fatigue.

The fatigue factor

Logbook violations are a serious matter in FMCSA’s new safety measurement system, Comprehensive Safety Analysis 2010. CSA 2010 will decouple the safety ratings of motor carriers from their last compliance review by using a new measurement system that updates carriers’ safety ratings automatically on a monthly basis.

Based on the number of HOS-related violations recorded in 2009 and so far this year, carriers that convert to electronic logs before CSA 2010 goes live have a rare opportunity to reduce their total violations by 50 percent.

Under current regulations, carriers that have an HOS violation rate of 10 percent or more will be required to use electronic logs. In June 2012, the mandate will apply to carriers with a 5 percent violation rate.

The Teletrac system will help prevent HOS violations from impacting Alamo Cement’s safety rating. “The Teletrac installation could not have come along at a more appropriate time,” Tamez says. “Teletrac has already helped us in monitoring unsafe driving practices and hours of service,” two of the seven Behavior Analysis and Safety Improvement Categories (BASICs) that the CSA 2010 program incorporates.

Top rankings of 2010 inspection violations

(through May 21)

The frequency of driver logbook violations to date shows how fleets can positively impact their CSA 2010 scores by converting to electronic logging.

The frequency of driver logbook violations to date shows how fleets can positively impact their CSA 2010 scores by converting to electronic logging.Shaw Transport, the private fleet for carpet and flooring manufacturer Shaw Industries, has been using eDriver Logs from PeopleNet for about five years. With 1,400 drivers, driver fatigue and logbook violations are not even in the fleet’s top 20 violations that will be included under CSA 2010, says Greg Wisenant, director of safety.

Real-time visibility

Today’s electronic logging systems feature wireless connectivity between the vehicle and office. By utilizing the real-time Web-based interface, fleet managers not only have advance warning of violations, but also instant visibility to changes that occur in drivers’ status.

“The whole idea of having electronic logs is to take advantage of having information in a real-time or near real-time environment,” says Rob Pallante, director of business development for Xata, one of the first companies to offer an electronic logging system. In terms of fatigue management, having real-time visibility into a driver’s duty cycle helps fleet managers avoid sending a message or otherwise interrupting the driver during off-duty rest periods.

“On paper logs, you don’t know what (drivers) are doing out there.” – Allen Lowry, director of safety, Central Refrigerated

Many companies strictly enforce such rules so that drivers aren’t disturbed during this time. “The last thing you want to do is wake up a driver,” Pallante says. Within the Web-based Xatanet application, fleet managers have the ability to see precisely when a driver changes his status from on-duty to off-duty.

Such technology also eliminates driver input from the equation. “We feel it is important in an electronic logging system to have automated driver status changes based on the movement of the vehicle,” says Drew Hamilton, executive vice president of Teletrac. With the Teletrac system, once a driver logs in and goes “on duty,” all other status changes are automated.

Jeff McGinney, safety director for Jetco Delivery, a Houston-based carrier with 100 trucks, says the company’s drivers are operating safer by using PeopleNet’s eDriver Logs. In the past, drivers were spending too much time trying to perform “creative logging.”

“Now drivers just log in and let it go,” McGinney says. Electronic logs help drivers focus on their surroundings and, as a result, drive safer. Based on internal studies, electronic logs save Jetco drivers 20 minutes a day, not to mention the time drivers would spend thinking and worrying about inspections, violations and out-of-service orders.

As part of using PeopleNet’s eDriver Logs application, drivers also can access current HOS status – such as their violations and available hours – by using the online Driver Center application on a PC or mobile device outside the cab.

Fleets also can have instant visibility into drivers’ duty status to help determine if fatigue is a contributing factor for unsafe behaviors. Companies that use Qualcomm’s Critical Event Reporting (CER) and QHOS products get drivers’ hours reported alongside critical safety events, such as a hard-braking incident or activation of a vehicle’s roll stability system.

Having the driver’s hours available instantly alongside an event can help fleet managers quickly assess if fatigue may have played a role in the event, says Chris Silver, senior product marketing manager for Qualcomm Enterprise Services.

Perhaps the biggest impact of electronic logs to fleet safety is to eliminate guesswork from HOS compliance. Inaccurate information not only can contribute to excessive driving and driver fatigue – and ultimately to accidents – but also can put your business at risk, as even petty logbook violations can accumulate to lower your safety score under the new CSA 2010 safety regime. n

Are the current rules working?

Few drivers using later available hours, survey finds

On the surface, the changes to the hours-of-service rules that were enacted in 2004 seem to have been effective in reducing accidents. According to the most recent accident statistics from the Federal Motor Carrier Safety Administration, between 2004 and 2008, the total injuries and fatalities from crashes involving large trucks have fallen by more than 22 percent and 19 percent, respectively.

In March 2010, the American Transportation Research Institute initiated a data collection effort to examine HOS safety impacts on the trucking industry. A total of 257 responses were received, representing more than 127,000 drivers and nearly 9 billion miles.

In comparing results from the two studies, the total collisions per million miles traveled for all fleets decreased 11.7 percent in 2009 from 2004. Preventable collisions per million miles decreased nearly 31 percent in the same time period.

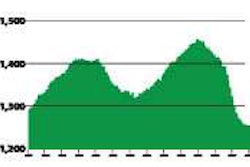

The 2010 ATRI study also looked at the correlation between the reduction in accidents and the changes to the HOS regulations, such as the addition of an extra hour of driving (11 hours). The study found that the new regulations governing drivers’ working hours had little effect on safety, as the data suggests that about 87 percent of all commercial vehicle collisions may occur within the first eight hours of driving. After the first eight hours, the frequency of DOT recordable collisions fell sharply.

This sharp drop in accidents and fatalities can be attributed to the fact that fewer drivers used the 9-10 and 10-11 hours for driving. In total, 12 percent of collisions occurred between the 9-11 driving hours. Sixty-six percent of drivers used part of the 9-10 hour at least once during the month, and 61 percent of drivers used part of the 10-11 driving hour. ATRI found that drivers generally used the 34-hour restart provision three or fewer times per month.

Based on these findings, a fleet that uses electronic logs to prevent drivers from exceeding 11 hours of driving each day would see little, if any, impact on safety since nearly all accidents occur within the first eight hours of driving. Not included in the study, however, was the impact of the continuous 10-hour break. By using electronic logs, fleets can ensure that drivers are not driving during this period.