Motor oil does many things inside an engine – regardless of whether it’s in a tractor-trailer hauling freight across the Midwest, a wheel loader laboring away in a quarry or a Toyota Corolla on its way to the mall.

Lubrication is the most important engine oil function, but today’s motor oil is formulated scientifically to do much more. Detergents and other additives help ensure optimal performance in an engine and help prolong oil life in a hellish environment.

But motor oil also acts as a big trash can, according to Stede Granger, OEM technical manager for Shell Lubricants. Although that’s not a particularly flattering comparison, the analogy is apt. Motor oil captures contaminants that enter the crankcase from the combustion chamber. Pistons go up and down, and the piston rings that seal those compression gases are not perfect, which allows for some leakage and, consequently, byproducts to enter the crankcase, where it is picked up by the oil. A high-quality engine oil will keep these byproducts suspended and prevent them from forming sludge, varnish, soot and other deposits in an engine.

That’s why you need an engine oil that features high-detergent and high-dispersant contents to keep those contaminants in suspension. When you drain the oil, the contaminants obviously come out with the oil. But if you allow oil to overstay its welcome in an engine, those ever-increasing contaminants can cause a lot of problems – even eventual engine failure.

Brent Calcut, supervisor of chemical technologies for Detroit Diesel Corp., says engine oil also becomes more acidic over time, which can lead to corrosion. Another consideration is filter life; as an oil filter accumulates more debris from the oil, stress on the filter media increases, and a media failure could spread high levels of contamination throughout the entire oil circuit.

1. Why should I consider extending drain intervals?

Len Badal, commercial enterprise manager for Chevron Global Lubricants, has seen many fleets working to extend oil drains well past OEM specifications. In some cases, these extensions are anywhere from 10,000 to 30,000 miles above OEM-recommended extended drain levels. As these intervals increase, additive formulation and the use of synthetic oils become crucial for ensuring engine protection.

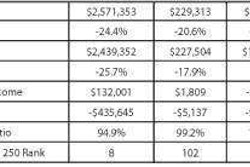

Also, there are solid economic reasons to extend drain intervals, such as reduced operating costs (purchasing less engine oil and filters), reduced waste disposal and reduced labor costs; meanwhile, top-line revenue performance increases since trucks don’t visit the shop as often and can spend more time on the road hauling freight.

On the other hand, fleet managers must be vigilant when implementing extended drain intervals. A fleet easily can lose all the aforementioned savings if it loses an engine due to wear or failure by trying to extend drains too far.

2. Why can’t I simply keep adding additives to extend oil life indefinitely?

Oil doesn’t last forever; it ages in ways similar to the human body. By exposing a lubricant to the elements within an engine – heat, air, water, glycol, particulates, shear and other factors – irreparable damage to the oil’s chemical makeup is done, says Jim Fitch, president and senior technical consultant with the Noria Corp. Additives can extend a lubricant’s life, but they can’t prevent degradation and aging.

Given that reality, lubricating oils need to be changed for the following reasons:

• There is a current or impending loss of the lubricant’s performance indicated through lack of friction control, wear control, deposit control or corrosion control;

• The lubricant has become a carrier of one or more harmful and nonremovable contaminants, such as sludge, glycol, bacteria or acids; and

• There is fear that the lubricant might need to be changed due to one or both of the previous two reasons without a convenient means to confirm. Err on the side of caution.

Depleted additives can be restored to extend the oil change interval and avoid the wasteful disposal of otherwise healthy oil. Fitch says users have two options:

• Additive reconstruction, the practice of giving certain depleting additives a “booster shot,” involves introducing an additive concentrate to circulating in-service oil. Only certain additives can be reconstructed with suitable success, and the practice usually is applied only to machines with large oil volumes, such as turbine oil, compressor lubricants and hydraulic fluids. Further, it only should be done after laboratory testing has confirmed that a lubricant has not experienced irreparable harm and there are no threatening contaminants that can’t be removed easily, such as glycol. Also, be sure the use of an additive supplement won’t impair performance of other lubricant properties.

• In case you can’t perform an oil change at the desired time, try a bleed-and-feed partial oil change, which involves draining a portion – perhaps one-third – of the oil volume, immediately followed by the introduction of new oil. The drained oil removes some of the contaminants, and the new oil dilutes the remaining contaminants and brings in fresh additive.

3. How do I determine a drain interval that will work for me?

Motor oil does many things inside an engine – regardless of whether it’s in a tractor-trailer hauling freight across the Midwest, a wheel loader laboring away in a quarry or a Toyota Corolla on its way to the mall.

But motor oil also acts as a big trash can, according to Stede Granger, OEM technical manager for Shell Lubricants. Although that’s not a particularly flattering comparison, the analogy is apt. Motor oil captures contaminants that enter the crankcase from the combustion chamber. Pistons go up and down, and the piston rings that seal those compression gases are not perfect, which allows for some leakage and, consequently, byproducts to enter the crankcase, where it is picked up by the oil. A high-quality engine oil will keep these byproducts suspended and prevent them from forming sludge, varnish, soot and other deposits in an engine.

That’s why you need an engine oil that features high-detergent and high-dispersant contents to keep those contaminants in suspension. When you drain the oil, the contaminants obviously come out with the oil. But if you allow oil to overstay its welcome in an engine, those ever-increasing contaminants can cause a lot of problems – even eventual engine failure.

Brent Calcut, supervisor of chemical technologies for Detroit Diesel Corp., says engine oil also becomes more acidic over time, which can lead to corrosion. Another consideration is filter life; as an oil filter accumulates more debris from the oil, stress on the filter media increases, and a media failure could spread high levels of contamination throughout the entire oil circuit.No matter how diligent you are, sooner or later motor oil will have to be changed. But how do you determine the optimum change interval for the trucks in your fleet?

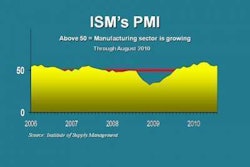

Detroit Diesel’s Calcut says several factors in recent years have affected the setting of appropriate oil drain intervals, including fuel sulfur, modern engine designs, exhaust gas recirculation levels and oil quality specifications. Significant reduction in fuel sulfur – via the introduction of ultra-low-sulfur diesel fuel – reduces the amount of sulfuric acid formation, thus improving the oil’s reserve alkalinity. Modern engine designs have improved combustion efficiency, resulting in less soot accumulation in the oil; however, this has been balanced by higher EGR levels, which increase the amount of soot accumulation. Historically, TBN and soot parameters were needed to determine the proper oil drain interval; with these recent changes, oil oxidation is becoming more important.

Oil drain optimization is not easy, but Noria’s Fitch is convinced that fleet managers who put forth the time and effort to determine appropriate drain intervals are the ones who consistently meet their maintenance budget savings goals and see greater profit potential.

Shell’s Granger is a fan of using fuel economy as a tool to help calculate drain intervals. Because contaminants in oil come from fuel being burned, a fleet that burns more fuel than another company operating the same or similar trucks is putting more contaminants into the oil per mile and therefore might have to drain the oil more frequently.

If you’re considering implementing an extended drain interval program, Fitch advises the following steps:

1. Reference the engine and/or vehicle manufacturer’s guidelines for oil intervals. While you most likely will choose to exceed the drain interval set by the manufacturer, its recommendation will help you establish a baseline for optimal vehicle performance. But for vehicles under warranty, exceeding the manufacturer’s guidelines may be problematic; in these cases, consult the manufacturer to make sure that exceeding the manufacturer’s guidelines does not void the warranty.

2. Know the drain interval recommended by the oil filter manufacturer. Are you using a product that is built for the drain interval at which you’re operating currently? If not, consider switching to an oil filter designed for longer service intervals.

3. Evaluate the fleet profile. The more severe service the fleet faces regularly – such as excessively hot or cold operating temperatures, loads and city driving patterns – the shorter the drain interval should be. Ask yourself the following questions:

• What are my expectations from the fleet?

• What improvements do I hope to achieve by pushing the drain interval?

• What kind of load, weather and road conditions are the vehicles operating under?

• What is the standard engine idle time? Long engine idle times may accelerate the rate of oil contamination and thus shorten oil drain intervals.

• What is our average fuel economy? How much could we improve it?

4. Consider how long you intend to keep the vehicles in your fleet. If the goal is to keep your current vehicles for 10 years or longer, pushing the drain intervals may not be in your best interests.

5. Forecast the cost savings associated with longer oil drain intervals. Consider necessary investments in upgraded supplies, shortened engine rebuild frequencies, etc.

6. Communicate any maintenance changes to the drivers. Once you determine the optimal drain interval for your fleet, communicate that interval to the drivers and logistics managers to ensure the vehicle comes in for maintenance as scheduled.

In some rare cases, finding an optimal drain interval is not clear after walking through the steps above. In such instances, call a meeting with the representatives from the engine, oil and filter manufacturers. When meeting with this group, outline the reasons for pursuing an optimal drain interval program and the desired goals. Together, they can determine if those goals are realistic and develop a program that includes the most appropriate products for your needs and circumstances.

Extending oil drain intervals can be safe and makes good economic sense for fleets, but Granger stresses that forming a partnership with the vehicle OEM and oil supplier is crucial for success. Once you’ve talked with them and established the baseline performance for oil changes, then you can use oil analysis to extend drain intervals slowly to a point that works best given your specific trucks and applications. n