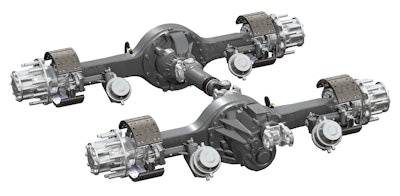

Dana – Spicer AdvanTEK 40 Tandem Axle

Dana – Spicer AdvanTEK 40 Tandem AxleDana announced Sunday at the Technology & Maintenance Council (TMC) Annual Meeting in Nashville, Tenn., that it is now offering axle ratios compatible with all seven configurations of the newly enhanced SmartAdvantage powertrain, a joint collaboration between Eaton and Cummins.

Dana says these configurations include the original small-step overdrive transmission and a new direct-drive option that delivers exceptional fuel economy in less-than-truckload and regional linehaul commercial vehicles with target cruise speeds of 62 mph and below.

Together with Cummins and Eaton, Dana has engineered these drivetrain options to help fleets maximize the benefits of engine downspeeding by creating a durable system that manages dynamic challenges resulting from readily available higher torque with less axle reduction.

“The benefits of engine downspeeding are undeniable, and we are partnering with industry leaders to advance this efficiency-boosting technology,” said Mark Wallace, executive vice president of Dana and group president of Dana On-Highway Driveline Technologies. “Our joint collaboration with Cummins and Eaton allows Dana to take a comprehensive systems approach, examining the integration of all components throughout the vehicle in an effort to fully optimize performance and make further drivetrain enhancements.”

Dana – SPL 250 Inter-Axle Shaft

Dana – SPL 250 Inter-Axle ShaftDana says its system includes the Spicer AdvanTEK 40 155 Series tandem axle, which offers the industry’s narrowest ratio steps, from 2.26:1 to 2.79:1, along with the SPL 350 driveshaft and SPL 250 inter-axle shaft, which are proven to be the most robust and reliable in their class. It also includes the company’s newest next-generation driveshaft, which the company says weighs 30 lbs. less than existing products and is tailored to address the specific torque-management strategies of individual commercial-vehicle manufacturers.

Dana says the Spicer AdvanTEK 40 155 Series tandem axle includes a full selection of downspeeding ratios, from 2.26:1 to 2.79:1, and options for a variety of Class 8 applications are now available at most OEM truck brands including Navistar, Kenworth, Peterbilt, and Volvo.

The SPL 350 driveshaft and SPL 250 inter-axle shaft also support the SmartAdvantage powertrain, and Dana says these components are designed to withstand the increased stress placed on the drivetrain by high-efficiency on-highway trucks configured for engine downspeeding.

Dana – SPL 350 Driveshaft

Dana – SPL 350 DriveshaftDana says its next-generation driveshaft offers a simplified installation process to reduce assembly costs for OEMs and improve ease of maintenance for truck owners. Available now for pre-production evaluation by OEMs, Dana’s latest innovation is designed for severe-duty, long-haul applications on high-efficiency Class 8 trucks, the company says. This driveshaft is ready for powertrains of the future that will be engineered for further engine downspeeding, enabling an axle ratio lower than 2.26:1, which is the fastest ratio on the market today, Dana says.

“Engine downspeeding is not a one-size-fits-all solution. Each OEM implements this efficiency-boosting strategy in its own way, resulting in very specific torque-handling requirements,” adds Wallace. “This next-generation driveshaft is the result of our continuous drive to deliver flexible solutions to meet each customer’s unique needs while further reducing weight and improving efficiency in our products.”