On the Chinese calendar, this year is the Year of the Fire Horse. On the Detroit calendar, 2026 is the Year of Horsepower.

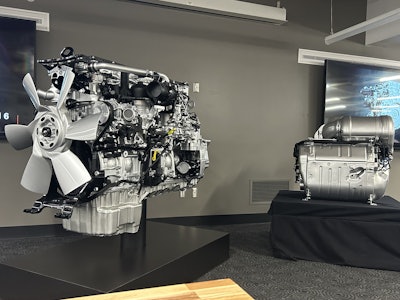

More than 100 trucks today produce the same nitrogen oxide emissions as a single truck in the 1990s; however, with the clock ticking toward the most stringent emissions standards in U.S. history, Detroit Diesel this week rolled out its sixth-generation engine platform—updated DD13, DD15, and DD16 engines that will meet the Environmental Protection Agency’s (EPA) 2027 regulations. These rules slash tailpipe nitrogen oxide (NOx) emissions by more than 80% and reduce particulate matter by 50%.

Following its introduction in 2007, each successive Detroit DD engine series generation—delivered in 2010 (Gen 2), 2013 (Gen 3), 2016 (Gen 4), and 2021 (Gen 5)—has met increasingly stringent emissions standards. Today, there are 1.2 million Detroit heavy-duty engines operating in on-highway and vocational applications in fleets across North America and other global markets.

Manufactured at Daimler Truck North America's (DTNA) Redford, Michigan, plant, the Detroit Gen 6 DD13 and DD15 engines will be available in January 2027, with DD16 production following in January 2028. Compliance for next year for DD16 engines is made possible through production credits.

Cost of compliance

Following a seven-year development cycle and having logged more than 8 million real-world miles before launch, Detroit's Head of Powertrain Engineering Greg Braziunas noted the Gen 6 DD lineup meets emissions standards without changing service intervals. Furthermore, components have been optimized for increased compression and fuel pressure.

DTNA Senior Vice President of Sales and Marketing David Carson said fleets are more closely scrutinizing capital expenditures this year and are looking for a greater return from their equipment investments. While numerous regulations have certainly been prodding the development of Detroit's next-generation diesels, Carson noted the DD Gen 6 lineup "is not just an emissions change. We are bringing value to the customer."

Braziunas added that before Detroit engineers ever knew what the final emission regulations were, "we always had in mind that we wanted to improve efficiency. So that's where we started. We started to develop the product with a customer focus in mind to really improve that value proposition for them. And then as the EPA Clean Truck Plan was passed and we incorporated those other requirements."

Added value is going to be important, as the cost of regulatory compliance is going to drive up the cost of next-generation trucks. By how much remains to be seen. While pricing for the Gen 6 DD power plants has not been announced, Carson said, "there are, let's say, pricing consequences," adding the total "is not a number that was quoted early by some of our competitors (upwards of $20,000), which was a massive price increase."

Aftertreatment

To meet compliance with stringent NOx requirements included in EPA’s 2027 standards, Detroit Gen 6 engines use a pre-Selective Catalytic Reduction (pre-SCR) system – containing the same robust, familiar elements of the main aftertreatment system (ATS) – positioned upstream of the primary ATS.

To meet compliance with stringent NOx requirements included in EPA’s 2027 standards, Detroit Gen 6 engines use a pre-Selective Catalytic Reduction (pre-SCR) system – containing the same robust, familiar elements of the main aftertreatment system (ATS) – positioned upstream of the primary ATS.

Braziunas said it was important to meet the looming NOx limits without reinventing the engine platform.

Detroit is utilizing a pre-selective catalytic reduction (pre-SCR) system. Positioned upstream of the primary aftertreatment system (ATS), this helps the engine reach operating temperatures faster—a critical factor in reducing emissions during cold starts and minimizing the need for parked regens. Since the pre-SCR system introduces DEF ahead of primary aftertreatment, it takes advantage of exhaust heat before the ATS gets to operating temperature. Hardware and functionality are nearly identical to the SCR in use since 2010.

"It's really familiar technology," Braziunas said, adding the company made "evolutionary steps" in current-generation solutions. "This product is very well-known."

A thermal control valve introduced on the Gen 5 DD13 is being rolled out to all Gen 6 engines. It articulates to increase the heat output from the engine, improving aftertreatment performance. It also enables faster aftertreatment warm-up, faster regen times, more passive regens in low duty cycle operations, lowers exhaust gas emissions, and virtually eliminates the need for parked regens for most applications.

The Gen 6 pre-SCR system sits on top of current One-Box footprint, preserving existing chassis space with no impact on back-of-cab packaging, an advantage for vocational customers and truck equipment manufacturers.

An electronically controlled oil separator removes oil from vapor inside crankcase, draining oil into pan and venting clean air outside. It's driven by an electric motor instead of oil pressure, maintaining consistent speed across engine operating range, reducing sludge build-up and reducing oil consumption.

Optimized turbo

The same asymmetric turbo that Detroit first launched in 2014 has been further enhanced to improve responsiveness and efficiency, while innovative thermal management features reduce regeneration frequency.

The Gen 6 turbo features optimized compressor and turbine wheel geometry, a polished interior compressor housing and an efficient ball bearing design introduced for Gen 5 expands to all engines for Gen 6

A new turbo wastegate actuator also improves braking performance and gradeability with greater power for high-altitude conditions. This also preserves heat in the exhaust; aiding regens and NOx catalyzation.

Fuel system redesign, new ratings

More responsive and consistent airflow from the turbocharger helped unlock three new power ratings. Vocational customers, specifically those looking for a 500 horsepower engine but aren't ready to take the leap up to 1,850 lb-ft torque, can get a DD13 with 505 hp and 1,750 lb-ft rating.

On the DD 15 can be spec'd with 425 hp and 455 hp, paired with 1,900 lb-ft torque, enabling greater downspeeding capabilities.

"Think about super fast axle actual ratios like a 2:05 paired with the direct drive transmission," said Detroit's Director of Field Sales Engineering Steve Collins. "You spin the engine slower, work it harder, and accomplish additional fuel efficiency savings, all without impacting performance because we're increasing torque."

Otherwise, the power ratings from Gen 5 models remain unchanged: up to 525 hp and 1,850 lb-ft for the DD13; up to 505 hp and 1,850 lb-ft in the DD15; and up to 605 hp and 2050 lb-ft for the DD16.

To prevent the collateral damage that emissions upgrades often cause to fuel economy, Detroit’s engineers overhauled the Gen 6 combustion process, swapping out the complex amplified injection for a streamlined fuel system that provides a more forceful and steady flow that help achieve a 3% fuel economy uptick.

Collins said the high-pressure fuel pump is now oil-lubricated, which is more efficient than the prior fuel-lubricated version. It is also less susceptible to low quality fuel and biofuel.

The simplicity of the new fuel system eliminates several internal parts and potential leak points; the forged fuel rail is mounted directly to the cam frame, and fuel lines have been strengthened to handle the added pressure.

The fuel filter module has been updated with water separation and draining for improved fuel system protection and now includes a standard heater element to reduce gelling and buildup in the fuel as it enters the system. This also helps overcome the loss of fuel heating from amplified injectors.

To ensure every drop of fuel counts, the team introduced asymmetric intake ports to create a high-swirl effect, which—when paired with next-gen injectors—perfects the air-fuel mixture. Finally, by adopting Miller cycle timing on the camshaft, the engine reduces parasitic compression loss and boosts the compression ratio, ensuring that meeting 2027 standards doesn't come at the expense of the fleet’s bottom line.

New oil system

An electronically controlled, variable displacement oil pump regulates the flow, reducing the work required to supply the oil circuit. If the valve fails it reverts to full pressure.

The crankshaft main bearings supply oil to two rod bearings, instead of one-to-one, reducing oil pressure while maintaining the same lubrication. These enhancements lead to lower oil consumption, reduced engine power consumption and increased efficiency.

The new engines will be compliant with a new engine oil category set to debut next year. Detroit has not yet decided what the factory fill will be for the Gen 6 line, but Braziunas noted that Detroit was the first OEM to use the current FA-4 engine oil as a factory fill due to its added benefits.

Tech integration

To maximize efficiency, Detroit engines are integrated with the Detroit Assurance safety system, applying radar- and camera-based systems that support safer decision-making through features such as Active Brake Assist, Adaptive Cruise Control, and Side Guard Assist. Detroit Connect complements these systems by providing real-time data, predictive analytics, and proactive support, giving fleets greater visibility into performance and maintenance needs. Together, they form an integrated, safety-driven powertrain ecosystem designed to improve reliability, reduce downtime, and help fleets operate efficiently throughout the vehicle lifecycle, Detroit said.

Emissions uncertainty looms

The U.S. Environmental Protection Agency said in November it will move forward with the 2027 timeline for its heavy-duty NOx rule, but the EPA is likely to amend parts of the regulation this spring. While those changes have not yet been formalized, they will likely center not on emissions, but on rolling back extended warranties and useful life limits—both cited by OEMs as major cost drivers of 2027-compliant equipment.

Braziunas said work on the next-generation Detroit engines took place with guidance from the EPA, but added, "Of course, there's still some uncertainty that they're looking at other aspects of the rule: warranty and other parts that I know we still don't have a decision on."

The American Trucking Associations sent a letter Wednesday to the U.S. Environmental Protection Agency asking the agency to reevulate its heavy-duty NOx standards "to avoid causing major operational challenges for the trucking industry."

"New emission control technologies required on model year (MY) 2027 trucks are unproven on the highway, and the trucking industry is concerned that a premature rollout will disrupt our ability to efficiently move freight," ATA President and CEO Chris Spear wrote. ATA favors granting non-conformance penalties to heavy-duty manufacturers, giving OEMs additional time to run real-world testing on these new emission control systems. The temporary nature of NCPs under the Clean Air Act would help to facilitate a smoother transition, ATA contends.

Even with fairly important questions swirling around EPA's final plan, Carson added that DTNA is confident in its path to meet the 35 milligrams per horsepower-hour NOx requirement for model year 2027 in EPA's Clean Trucks Plan.

All Detroit engines are manufactured in the US at the Redford, Michigan campus. Home to North American engine and component research and development for Daimler Truck North America, as well as engine, transmission and axle production, the facility employs more than 2,000 people.

All Detroit engines are manufactured in the US at the Redford, Michigan campus. Home to North American engine and component research and development for Daimler Truck North America, as well as engine, transmission and axle production, the facility employs more than 2,000 people.