Editor’s note: This is the second installment of a two-part series on how carriers have accelerated their use of technology to be more nimble and responsive during COVID-19. Part 1 ran last week.

Freight markets have been volatile during COVID-19, making load and route planning decisions more complex. Besides rates fluctuating, shippers and receivers have been shortening business hours, shifting appointment times and operating docks with reduced staff.

Using technology for route planning and to match assets with loads has become more critical, and technology is giving carriers of all sizes a way to adapt more quickly.

Optimization for all

N&G Trucking, an Atlanta-based truckload carrier with dry van, refrigerated and flatbed operations, started using Optym’s cloud-based transportation management software (TMS) system before the coronavirus pandemic hit.

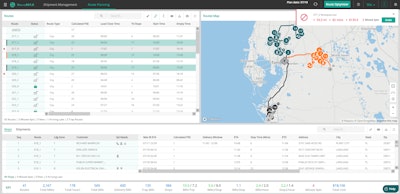

Optym’s Axele platform brings predictive analytics for load planning to small and medium sized truckload carriers.

Optym’s Axele platform brings predictive analytics for load planning to small and medium sized truckload carriers.“I’ve always been in trucking and have always tried to use technology to my advantage,” said Bogdan Bota, fleet manager for the seven-truck company.

Bota was using multiple websites to pre-plan loads, from the company’s TMS to load boards and its electronic logging device (ELD) system. Each had a separate web portal, but Optym’s Axele system has pre-built integrations to the DAT load board and the ELD system N&G uses from Samsara.

“That was what convinced me to use [Axele],” Bota said.

Optym developed Axele to fit the needs and budgets of truckload carriers with between five and 50 trucks. The company has developed software for some of the largest less-than-truckload (LTL) trucking companies and airlines to optimize planning and scheduling.

“Ultimately, with this product, the only way we are going to gain success is if we truly deliver a product that is going to drive additional incremental revenue to a carrier,” said Optym Chief Executive Vic Keller.

Bota sees load recommendations in the Axele TMS from the DAT load board based on the fleet’s preferences for length of haul, timing, equipment, distance, deadhead miles and more. The recommendations are plotted visually on a map for each truck to show the connections that will optimize revenue per day for the first load and the next load in the destination area, and so forth.

“It helps a lot with figuring out which [load] gives us the best profit,” Bota said. At most, Bota plans two or three loads in advance, because “we’ve seen a lot of craziness going on in the industry,” he said. “You don’t want to go too far ahead.”

The time savings from using the Axele TMS have been the most important return on investment, Bota said. “I don’t have to spend an hour looking for loads, entering the load and making sure the driver has enough hours and all that,” he said.

Rate confirmations with customers are managed within the system, and with the “press of a button,” the system creates an order and sends the details – addresses, purchase order numbers and appointment times – to drivers via a mobile app. It also sends a shipment tracking link to the customer with the estimated time of arrival (ETA).

Bota estimates he is saving at least 30% to 40% in time with the TMS. He has used the time savings to grow the fleet by finding another two owner-operators that are “getting ready to lease to us.”

Optym currently is offering Axele to carriers as a 30-day free trial. During this period, a carrier can use features normally reserved for the premium service.

Route planning

Optym spent three years developing Axele based on experience in the LTL sector with a TMS system for linehaul and a pickup-and-delivery route planning system. The company’s LTL clients include Saia (CCJ Top 250, No. 24) and Estes Express Lines (No. 12).

Optym’s RouteMax software is used by LTL carriers to optimize pickup-and-delivery routes.

Optym’s RouteMax software is used by LTL carriers to optimize pickup-and-delivery routes.During the health pandemic, LTL carriers have been using features in the RouteMax route planning system to adjust the time windows for pickups and deliveries based on customers’ changing business hours. The optimization software adjusts routes and sequences to ensure that drivers arrive at the right time, said Raguram Venkatesan, Optym’s director of trucking solutions.

As drivers complete morning deliveries, the software positions the assets to end up at strategic locations and times to begin the pickup routes to minimize costs, Venkatesan said.

Another way carriers are using RouteMax to increase efficiency is by marking delivery locations with a geofence to give the customer an automatic alert when a driver arrives, so the customer is on hand to receive the freight.

“Intelligent scheduling and routing used to be a luxury before, but it is going to become a mandatory feature in light of COVID-19,” Venkatesan said.

Checking trailers

Load and route planning tools are far from the only technology fleets have been using to adapt to changes during the pandemic. Another area of focus has been using telematics data from truck and trailer assets.

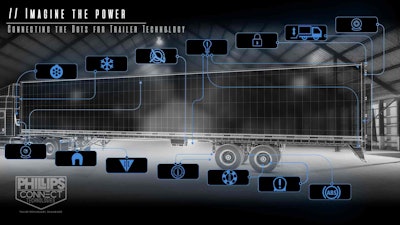

The goal for the company’s Phillips Connect division is to unite data from all of a trailer’s components — lights, brakes, tire inflation systems, etc.— and combine it with its own sensors for fleets in a more cost-effective way, said Bill Ellis, president for Phillips Connect.

The Phillips Connect telematics platform currently is deployed on about 10,000 trailers. The company has relationships with ELD and telematics suppliers to pair data from trailers. With the integration it has with Geotab, a driver could get an alert if he or she connects to the wrong trailer assignment.

Phillips Connect is working on a new trailer “precheck” feature that fleets can use to conduct a virtual inspection of trailer components remotely, Ellis said.