Truckload carrier affects safety, fuel performance with driver behavior program

Nussbaum Transportation CEO Brent Nussbaum, left, and Jeremy Stickling, director of human resources and safety, led the company’s efforts to leverage event recorder and ECM data to measure driver behavior and retool its fuel scorecard program.

Nussbaum Transportation CEO Brent Nussbaum, left, and Jeremy Stickling, director of human resources and safety, led the company’s efforts to leverage event recorder and ECM data to measure driver behavior and retool its fuel scorecard program.“Honesty. Integrity. Character. Excellence. Benevolence.”

Those five words scrolled above the reception desk greet every visitor that enters Nussbaum Transportation’s headquarters in Hudson, Ill. It’s easy to look past them, as they are boilerplate material in many company mission statements. But if you stick around long enough, it’s soon clear that Nussbaum isn’t just paying lip service to these five values – they are rooted firmly in the company’s culture.

That environment has helped generate a host of innovations, including two that earned Nussbaum recognitions as a CCJ Innovator, first in 2012 for its role in developing a heavy-duty dual-purpose dry van trailer, and again in 2016 for leveraging event recorder and engine control module data to measure driver behavior and retool its fuel scorecard program. The latter has earned Nussbaum Transportation CCJ’s 2017 Innovator of the Year award.

MIGRATING FROM MPGS

Fuel incentive programs are nothing new to trucking. When diesel prices eclipsed $4 a few years ago, they became commonplace. Nussbaum’s first dive into driver bonuses tied to mpg results began in 2009 with its Driver Excelerator performance-based pay program, a four-pronged scorecard system that included a fuel component that measured readily trackable metrics for fuel economy, idle time, fuel purchasing compliance, on-time deliveries and out-of-route mileage.

Excelerator bonuses are awarded on a per-mile basis, with an average of 3 cents per mile added to a driver’s base mileage pay. Top-performing drivers earn as much as an additional 6 cents per mile over base. Nussbaum uses the Excelerator program to place drivers into three categories – gold, silver and bronze.

For the most part, the fuel scorecard was a success. Nussbaum now has one of the leading fuel economy averages in the truckload segment – 8.5 mpg for its fleet of 300 trucks.

Over the next several years, Nussbaum’s IT department, along with Jeremy Stickling, director of human resources and safety, revamped the Excelerator program’s fuel scorecard to eliminate complaints about fairness based on route attributes.

“The question at the time was ‘How do we take the subjectivity out of this – the circumstances and situations that drive fuel economy up and down?’ ” says Stickling.

The company went to frustrating lengths to normalize results based on external factors such as load weight, truck age and model, trailer type and weather.

“We were looking at variables like wind speed in Nebraska and driving through the mountains,” says Brent Nussbaum, chief executive officer. “You wouldn’t believe the amount of data we poured through the IT department to put together the right score.”

The changes helped level the playing field but ultimately didn’t eliminate all external variability and load/route subjectivity, and management continued to field questions and complaints from drivers. Stickling admits the scoring system, which took mpg results and added weighted point adjustments to normalize the results, was too complex for drivers to track and still left the company guessing as to what was causing poor fuel economy performance.

“We were asking drivers to try a new habit or driving skill, but there wasn’t anything concrete to point to,” says Stickling. “The suggestions we gave them were assumption-based. It might have been something they already were good at.”

CHANGING BEHAVIORS

In 2015, Nussbaum began looking for a way to affect fuel economy by measuring driving behaviors and habits. “We didn’t have any real insight,” says Stickling of the old fuel scorecard. “We were waiting until somebody had a way to get us the data to measure habits reliably.”

At the same time, Nussbaum was weighing its options for onboard event recorders when it came across SmartDrive. The company told Nussbaum its system tracked g-force sensor data and could be tied directly to the ECM and allow access to throttle usage and speed management data.

After rolling out the onboard event recorders fleetwide – a carefully managed process that resulted in only one of the company’s 315 drivers leaving – Nussbaum collected three months of data points and looked for reliable patterns between driving behavior and fuel economy. Stickling’s team identified four key areas – speed management, smooth driving, throttle usage and space management – and last July it replaced its fuel scorecard component within the Excelerator program with a new behavior/habit scoring system that correlates safe driving with fuel performance.

Today, Nussbaum has grown its long-haul truckload operation and serves 48 states with 300 tractors, 315 drivers and 750 trailers.

Today, Nussbaum has grown its long-haul truckload operation and serves 48 states with 300 tractors, 315 drivers and 750 trailers.The speed management metric uses the ECM’s speed bracket data to measure how much time is spent at each 2-mph speed interval. Nussbaum’s fleet is governed at 65 mph, and “if a driver is going 63 mph and comes up on someone going 62 mph, they have an extra 2 mph and can make a safer pass,” explains Stickling. “We start giving points when people back off the governor. They are more likely to have traffic going by them rather than them coming up on traffic.”

The smooth driving metric uses the event recorder’s g-force sensor data. Nussbaum measures acceleration and braking as well as left- and right-axis movement. It scores driver performance on a weighted scale – 60 percent for acceleration/braking and 40 percent for lateral, and normalized by miles traveled under 45 mph.

Throttle usage is measured by how much of the throttle is actuated using trip bracket data from the ECM. Data is collected, and drivers are scored in three categories: takeoff, traffic and highway. “When a driver sets cruise to 65 mph and throttles up to hold that speed every time the predictive cruise control feature slows the truck down, their foot is on the floor even though they are in cruise mode,” says Stickling.

In space management, the system uses the following distance data that is measured every time the event recorder is triggered or an alert from the collision mitigation system occurs. Following distances are ranked in four categories: 0 to 1 second, 1 to 2 seconds, 2 to 3 seconds and 3 to 4 seconds. “To work these fuel habits, you have to isolate yourself from other traffic,” says Stickling.

To simplify the scoring system, Nussbaum replaced its old points-based approach with a simpler 10-point scale in each of the four habit/behavior scoring system metrics.

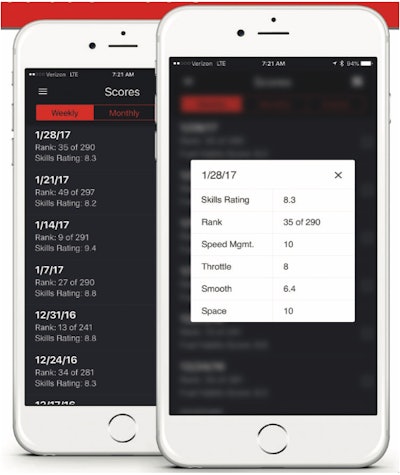

Nussbaum drivers can check their personal statistics on a real-time basis through the internal Nussbaum LiNK app.

Nussbaum drivers can check their personal statistics on a real-time basis through the internal Nussbaum LiNK app.“This is about as simple as it gets,” says Nussbaum. “The last one had too many factors built in, and the driver gets frustrated with a mass of information in front of him to work with. If you do these things with your driving, it not only will make you safer, but it will get your fuel performance up.”

Official habit/behavior scoring system results are tabulated and published in a monthly ranking of all company drivers. Drivers also can check their personal statistics on a real-time basis through the PeopleNet onboard computer or through the internal Nussbaum LiNK app.

The new habit/behavior scoring system already has impacted Nussbaum’s safety performance. Since June 2016 – the month before the scoring system was rolled out – the company’s percentile ranking in the Compliance Safety Accountability Crash Indicator BASIC has dropped from 37 percent to just 10 percent in February.

In the same period, Nussbaum had no preventable DOT-recordable accidents, and insurance premiums have dropped 7 percent. The company also recorded its lowest score in the CSA Unsafe Driving BASIC in two years.

“Since we now have these behaviors on a scorecard, we have drivers thinking about how they drive the truck rather than what their mpg is,” says Stickling.

MORE TO COME

Nussbaum Transportation continues to push the envelope with new innovations throughout the organization. One such effort is DashRabbit, a new tool in development in the company’s IT department that will allow greater communication and load visibility.

The DashRabbit system will track each load entering Nussbaum’s freight network and allow driver managers to track load status in real time. The system will alert the driver manager if a load isn’t going to make its appointed delivery time so they can call the driver and determine whether they need to find another driver or have a customer service manager contact the customer to schedule another delivery appointment.

“Another thing DashRabbit will do is notify a driver with a recommended leave time through a push alert on the Nussbaum LiNK app,” says Nussbaum. “If the driver is late leaving with a load, the system notifies our driver managers, who can call the driver to find out what is going on.”

Nussbaum’s marketing department also is developing a content library with in-house videos ranging from how to install tire chains and change fuel filters to how to send in paperwork digitally. The videos will be pushed out to drivers using the Nussbaum LiNK app.

ALL ABOUT DRIVERS

Nussbaum’s driver-friendly work environment is reflected in its low turnover rate of 29 percent, an exceptional mark in the long-haul truckload segment. The company’s drivers-first approach has been a focus since the company was founded in 1945.

“My dad was a very strong Christian man and ran his business as such,” says Nussbaum. “He believed if you took care of your people, everything else would take care of itself. And he was really good at that even in the most difficult times. He’d keep them working even if he had to send them over to paint his house.”

Nussbaum continues its faith-based principles today. Of its fleet of 750 trailers, 140 have trailer graphics highlighting two of the company’s core beliefs with “Celebrating Faith & Family Since 1945” and images of fathers and sons fishing, family campouts, a husband and wife taking a walk and more. The purpose, says Nussbaum, is to highlight what is truly important in life. “You cannot believe the comments we get from people in appreciation of the trailer wraps,” says Nussbaum. “We were totally unprepared for the positive response from drivers and how many Christian drivers wanted to drive for us.”

Nussbaum makes family time a priority for its drivers and currently is working to reduce missed home time on the weekends, something Nussbaum says “is a challenge when you run 48 states.” Currently, 85 percent of drivers are home on the weekend, and the company recently began an effort to get all drivers with scheduled home time within 300 miles of their home by noon on Friday.

“One of the biggest causes of turnover is a driver who has a desire to be home on the weekend and we miss that,” says Nussbaum.

Another driver focus at Nussbaum is the onboarding process and improving retention. At present, 85 percent of new driver hires stay with the company through 90 days, about double the industry average.

Nussbaum subscribes to Franklin Covey’s 4 Disciplines of Execution, and one of the fleet’s goals is to increase retention beyond one year from 45 percent to 60 percent. “At that point, they have learned who we are and are more likely to stay at least three or four years,” says Stickling.