Boyd Bros. Transportation

Like just about every other regional or national carrier in the industry, Boyd Bros. Transportation faces common challenges. Scrutiny under Compliance Safety Accountability, pending changes to the hours-of-service rule, a mounting driver shortage and increased highway congestion all constrict capacity and threaten productivity. What makes the Clayton, Ala.-based flatbed carrier different than most fleets is that it isn’t taking these changes lying down.

Instead, Boyd Bros. took the bull by the horns, pioneering a solution that could offset many of these challenges while potentially revolutionizing a portion of the flatbed market. For this reason, Commercial Carrier Journal is proud to name Boyd Bros. the 2013 CCJ Innovator of the Year.

Forging a new path

In 2009, Boyd Bros. president Richard Bailey challenged his executive team to develop an intermodal solution for flatbed freight for long-distance shipments to increase capacity.

Boyd Bros. Raildeck

At the time, intermodal freight was being employed by some of North America’s largest dry-van fleets, and refrigerated haulers were beginning to explore the possibilities. But because of the very nature of open-deck cargo, no one had explored a flatbed-intermodal solution seriously.

“We felt like if dry vans could do it, and reefers were starting up, why couldn’t flatbed?” says Bailey. “We felt like we could make the economics work.”

Boyd Bros. established a new division, Boyd Intermodal, and approached a number of rail companies about partnering to develop a solution – but had little initial success. The challenge before Boyd Bros. was creating a product that would integrate seamlessly with a railyard’s intermodal loading operation.

“They told us, ‘Don’t bring anything into the yard that we have to set at the end of the lot and, after we load our intermodal train, have to determine how this fits,’ ” recalls Lee Wagner, director of international sales for Boyd Bros.

In 2010, Burlington Northern and Santa Fe stepped in and introduced Boyd Bros. to Raildecks, a small Canadian company that also was looking to develop a flatbed intermodal solution that would allow easy loading and unloading between railcar and trailer chassis.

The two hydraulic gantry arms on either end of the deck allow the flatbed to function just like any other container, with the ability to double-stack loads.

Together, Boyd and Raildecks began work on a flatbed intermodal concept, ultimately developing a flatbed “container” that has two hydraulic gantry arms on either end of the deck that can be raised and lowered as needed. The gantries allow the flatbed to function just like any other container, with the ability to double-stack loads and even place the flatbed on the bottom dwell with a fully loaded box container in the top position.

But perhaps the best feature of the new design is the ability to lower the gantry arms and stack empty flatbeds – up to four high – for the return leg. “We can ship four loads to the Northeast and send them back empty in one load,” says Bailey. “That is a competitive advantage because that is something dry vans and reefers can’t do.”

Boyd Bros. quickly realized capacity improvements during the rollout phase of its intermodal operation. “Our local operator with a daycab can shuttle four or five intermodal loads into a customer in the same day as one or two of our over-the-road drivers,” says Bailey. Additionally, the company was able to remove 12,000 tons of carbon dioxide emissions last year during the 820-load million-mile test phase.

Boyd Bros. has 52 Raildecks in operation, each allowing the company to haul up to 44,500 pounds safely. Boyd and Raildecks are currently on their fourth-generation Raildecks design – manufactured by Jasper, Ala.-based Fontaine Trailer – that, when paired with new lightweight daycabs, will allow Boyd Bros. to haul 46,000 pounds. “That’s the magic number,” says Bailey. “That converts a heck of a lot of freight from over-the-road to intermodal for us.”

Intermodal currently makes up about 2 percent of the company’s shipments, but Boyd Bros. expects that number to grow dramatically as its customers gain confidence in the concept and rail companies continue to improve infrastructure.

“In five years time, there is the potential for intermodal to be 20 to 25 percent of our business,” says Bailey.

Pairing up

In order for intermodal shipping to remain profitable, Boyd Bros. has to be selective about the lanes where it operates. The company’s ideal scenario for intermodal is city pairs with lengths of haul greater than 700 miles with dray operations on either end of 75 to 100 miles.

“We felt like if dry vans could do it, and reefers were starting up, why couldn’t flatbed?” – Richard Bailey, president, Boyd Bros.

“It’s a very specific point-to-point service,” says Wagner. “Then we have to build critical mass in those lanes.”

Because of these limitations, not every customer is suited ideally for intermodal service.

“We can’t provide intermodal service to a customer that is 250 miles from an intermodal yard, or even a customer that sits right next to an intermodal yard that wants to ship to Four Corners, New Mexico, where there isn’t an intermodal yard for 500 miles,” Wagner says.

During the test phase, the company operated in six lanes between the Southeast and Northeast, and since has expanded its intermodal network to Chicago and points west, opening up new customer opportunities in the process.

“We didn’t serve the West Coast before [intermodal], so that’s virgin territory for us,” says Bailey. “We will serve that market primarily out of Memphis and Chicago and into Los Angeles. We already have a good lane now between Chicago and Denver.”

Boyd Bros. even has hopes to expand its intermodal operation into Mexico with southbound service into Monterrey. “That holds a lot of potential because you don’t have to worry about a border crossing and transfer service,” says Bailey.

Gaining acceptance

Like any new product or service offering, customer acceptance is an unknown. In Boyd Bros.’ case, some customers got onboard with the company’s intermodal concept from the beginning, while others are taking a wait-and-see approach. Boyd Bros.’ sales team has to be proactive with Raildecks product demonstrations at customer locations in order for them to understand the concept.

“The biggest concern customers have is if it can be as service-sensitive as truckload service,” says Bailey. “And in a lot of our lanes, it is. You can actually go to the West Coast faster via intermodal than by sending a truck out there. And we can offer two-day intermodal service from Atlanta to the Northeast – that is the same as truckload service.”

All intermodal flatbed loads require special securement to meet Association of American Railroads regulations, which are different than standard flatbed truckload requirements. “There is a customer learning curve on loading and securing, but once we get them over that hurdle, it works,” says Bailey.

Doing the right thing

When it comes to finding ways to serve its customers more efficiently and effectively, Boyd Bros. never has shied away from trying new things. That’s essentially how the idea for the intermodal stack train came about, so the 57-year-old company probably isn’t finished with its innovations.

The hydraulic gantry arms have the ability to place the flatbed on the bottom dwell with a fully loaded box container in the top position.

“When a customer comes up with something different, we’ll sit down and talk to them about it,” Wagner says. “Some things don’t work out, but we’re willing to look at it.”

One recent idea that didn’t pan out as Boyd Bros. hoped involved moving flatbed freight via RORO (roll-on roll-off) ocean-going vessels designed to carry wheeled cargo driven on and off the ship on their own wheels.

Boyd Bros. had a Mexico customer open to using RORO ships to receive flatbed freight, and the companies tried it for about six months. But the shipping company providing the RORO transport “didn’t do a good job marketing it,” Wagner said. On a ship that could hold 250 trailers, some trips hauled eight Boyd flatbeds – and nothing else.

Boyd Bros. hasn’t given up on water transport, either bluewater (ocean) or brownwater (river), and the company now has a couple of studies under way to look at it again. “It’s economically cheaper to ship with water,” says Wagner, explaining the company’s reasoning for sticking with the idea. With the right lanes and customers, water transport is a win-win for the hauler and the end user, he says.

Looking out for the customer always has been part of Boyd Bros.’ culture – as is doing the right thing for its people, both in the office and out on the road. Business Alabama magazine recently recognized Boyd Bros. as a “Best Company to Work For in the State of Alabama 2012” in the large campus category.

In 2012, the Truckload Carriers Association recognized Boyd Bros. in its annual Best Fleets to Drive For survey and contest. Two years earlier, the company was TCA’s overall Best Fleet for Company Drivers.

Chris Cooper, Boyd Bros. chief operations officer and grandson of company founder Dempsey Boyd, called the TCA award “one of the greatest single achievements in our company’s history. It’s a reflection of our culture and how much we value our people. Certainly, it shows our dedication to creating a good environment for our drivers to operate. Thanks to all of our associates inside that make a difference in the lives of our drivers.”

To win its category, Boyd Bros. demonstrated solid and consistent results across a variety of areas. The company has invested in a simulator to help drivers learn and improve safe driving techniques, developed a mentoring program tied to the simulator’s usage and established a benchmarking program to track and manage driver performance on the road.

Boyd Bros. uses structured performance reviews to ensure that new hires transition smoothly, consults with a driver advisory board to guide company policy and offers a variety of educational and career development opportunities. The company also maintains a formal wellness program and provides the services of a company chaplain, who doubles as a certified financial planner.

Fleets in TCA’s annual competition have to be nominated by at least one of their drivers, either a company driver or an owner-operator. Nominated fleets are evaluated in areas such as driver compensation, pension and benefits, professional development, driver and community support, and safety record.

“The Boyd family has always listened to our drivers,” Bailey says. “We want to address their needs in every possible aspect of their lives, from instilling safe driving habits to helping maintain their health and ensuring their financial stability. It’s good to know from receiving this recognition that our drivers recognize our efforts and are happy driving for us.”

This year, Boyd Bros.’ subsidiary in Tuscaloosa, Ala., WTI Transport, was named a 2013 Best Fleet to Drive For.

Growth and safety

A growing company such as Boyd Bros. fully understands how critical it is to keep its current drivers while finding new ones. In 1956, Dempsey Boyd and his brothers founded Boyd Bros., which has grown to become one of the nation’s largest flatbed trucking companies, specializing in time-sensitive transportation of iron and steel products, lumber, roofing and other building commodities.

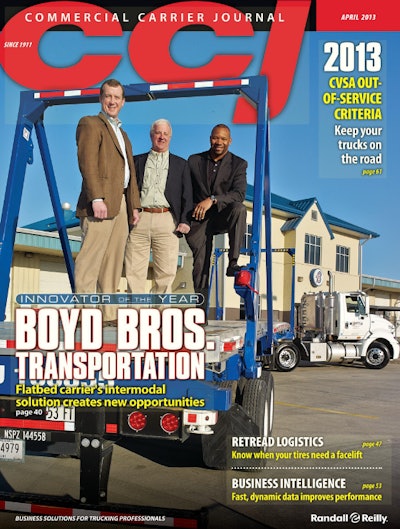

Richard Bailey, Boyd Bros. president, Cory Gilliard, intermodal director, and Chris Cooper, chief operations officer, accept the 2013 CCJ Innovator of the Year award.

Boyd Bros. operates primarily throughout the eastern two-thirds of the United States, serving high-volume time-sensitive shippers that demand time-definite delivery. The company has full-service terminals in Birmingham, Ala., Cincinnati and its home offices in Clayton, as well as service centers in Greenville, Miss., Cartersville, Ga., and Cofield, N.C.

The same company that had 800 trucks at the end of the recession in 2009 now has nearly 1,200, and Bailey says Boyd Bros. is looking at further growth if it makes sense strategically and geographically. The company now is looking to hire drivers based closer to its regional lanes instead of mostly out of its home base in the South, which should help with hours-of-service compliance and retention since drivers will be closer to their home bases.

Late last year, the company acquired Mid Seven Transportation, based in Des Moines, Iowa, and Bailey says Boyd Bros.’ new ownership of Mid Seven is expected to provide additional resources to that company’s customers and new opportunities for its employees and owner-operators. Mid Seven’s revenues are expected to exceed $6 million this year.

Mid Seven, which uses solely owner-operators, focuses primarily on the Midwest, with extended lanes in the South, Northeast and Southwest. Its freight includes steel, machinery and agricultural equipment transported by flatbeds and drop-deck trailers.

“We plan to operate Mid Seven autonomously as a separate subsidiary,” says Bailey, explaining the desire for the company to retain its own brand and identity for its customers and employees. “Mid Seven has some of the best owner-operators and employees in the industry, and we are especially proud of their safety and service culture.”

Hiring and retaining the best drivers is critical to maintaining Boyd Bros.’ standards for safety, another area in which the company proudly excels. Boyd Bros. is an annual fixture atop the American Trucking Associations’ Safety Management Council’s honorees for achievements in safety, both in the flatbed industry segment and for overall recognition.

James Ransom, Boyd Bros.’ director of safety, last year received the 2012 National Safety Professional Award of Excellence from ATA’s SMC in recognition of his contributions to the company’s safety programs and experience. In 2009, TCA recognized Ransom with the Clare C. Casey Award, the association’s Safety Professional of the Year honor.

ATA’s SMC honored Ransom, a 40-year veteran of transportation – three decades of which have been devoted to safety – for his ability to constantly retool and expand his safety operations and programs to meet Boyd Bros.’ growth. Over the last six years, his programs and leadership have enabled the company to decrease its total accident frequency ratios.

“We congratulate him for receiving this well-deserved award,” says Gail Cooper, Boyd Bros.’ chief executive officer, Dempsey Boyd’s daughter and Chris’ mother, adding that the entire company was proud of Ransom and the job he does for the hauler.

Boyd Bros. also has earned numerous accolades from the Alabama Trucking Association, the Better Business Bureau, Wreaths Across America, the Federal Motor Carrier Safety Administration’s “Share The Road” and several customers. In addition, the company has earned C-TPAT (Customs-Trade Partnership Against Terrorism) certification from U.S. Customs and Border Protection – further evidence that Boyd Bros.’ ambitions and reach extend beyond the U.S. border.

“We move freight that you can fit on a 53-foot flatbed trailer,” Wagner says. “We’ll move it however we can move it.”

About the award

Commercial Carrier Journal’s editors recognize innovators throughout the year and select one for special recognition as Innovator of the Year. Innovators considered for the current award were those recognized in the magazine in 2012.

Innovation in any aspect of the operation is eligible for recognition. To qualify, the carrier must operate at least 10 power units in Classes 3-8 and maintain a satisfactory safety rating, if rated. Selection of innovators for recognition is at the sole discretion of CCJ’s editors.

This year’s award was announced and presented at the CCJ Innovators Summit, a networking event for current and previously recognized innovators held Feb. 6-8 at the Hawks Cay Resort in the Florida Keys. Representatives of innovative trucking operations updated one another on their initiatives.

The CCJ Innovators program is sponsored by PeopleNet, Castrol, J.J. Keller and Freightliner. For more information on the program and links to previously recognized innovators or to fill out the online nomination form, go to www.ccjinnovators.com or contact Jeff Crissey, CCJ editor, at 800-633-5953.

– See more at: http://www.ccjdigital.com/all-aboard-boyd-bros-intermodal-solution-brings-them-innovator-of-the-year-award/#sthash.y41C4nYQ.dpuf