It stands out as a memorable showdown, a revealing “man vs. machine” moment in which a driver was one-upped by digital tire analytics.

Micah Tindor, product manager, Connect Fleet, for Goodyear Tire & Rubber Co., recalled how a driver had conducted a pre-trip inspection and thought all was well with the truck’s tires. That wasn’t the case.

“We had a predictive alert go out, and the driver was informed of the alert and said, ‘No. I did a pre-trip. I don’t have an inflation issue,’ ” Tindor said during a webinar on tire management held during the 2020 American Trucking Associations’ Management Conference & Exhibition in late October.

Since the driver’s fleet manager recently had set a key performance indicator (KPI) of distinguishing actual tire alerts from false ones, the driver agreed to double-check the tire, hoping to outwit the computer.

As part of the Michelin Tire Care tire maintenance, Michelin uses Radio Frequency Identification (RFID) technology in its commercial truck tires and retreads, enabling fleets to better manage their tire assets throughout the full life cycle.

As part of the Michelin Tire Care tire maintenance, Michelin uses Radio Frequency Identification (RFID) technology in its commercial truck tires and retreads, enabling fleets to better manage their tire assets throughout the full life cycle.“The driver wanted to prove everybody wrong and wanted to show that the system wasn’t very successful. [He] went out and actually checked and it turned out that they did have a slow leak,” Tindor said during ATA’s virtual session on Digital Best Practices for Tire Life Cycle Management.

With tires ranking as the second highest fleet expense behind fuel, catching an issue before it becomes a costly and potentially dangerous problem down the road makes digital tire analytics all the more appealing. Coupled with keeping a closer eye on tread-life and tire casing KPIs, the process can improve the bottom line.

“A digital tire management program can help prolong casing life by providing an operational usage history of the respective tire asset,” said Karl Remec, business segment manager for long distance transportation at Michelin. “Knowing the historical load, pressure and temperature conditions in which a tire has operated over its life, as well as the number and type of repairs (both as a new tire and retread), can allow fleet managers to make more informed decisions about how to manage those tires during their service life.”

Improving tire management means improving tire pull points, which is something that digital data can deliver.

“Digital tire analytics can also help a fleet track the tread depth of the tires when the tires are removed,” said Phil Mosier, Cooper Tire manager of commercial tire development. “You can then determine how well the fleet is doing at removing tires at their intended pull point. If, on average, the tires are being pulled too early with deeper tread than the pull point, then the fleet is leaving money on the table for more mileage they could have gotten out of that tire’s tread.”

Realtime alerts can play a critical role in a digital analytics tire maintenance program.

Realtime alerts can play a critical role in a digital analytics tire maintenance program.“If the tires are being removed past their designated pull point, Mosier continued, then the tires may be getting too worn and are at a higher risk of punctures and damage to the tread. “This can also reduce your chances of retreading that casing,” he said.

A properly tooled digital analytics program can also communicate company policy and expectations to technicians “in a timely manner without having to communicate through fax and a paper record and sending it out to HQ and getting approval and involving many other team members,” Shaun Hartoog, digitial solutions specialist at Dana Incorporated, said during ATA’s webinar.

Streamlining and improving tire maintenance through digital analytics can cut back on costly tire infractions, which remain a top out-of-service violation.

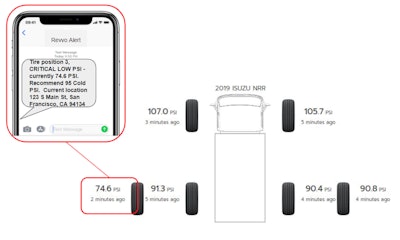

“Revvo specifically helps fleets increase the life on each tire, reducing overall tire spend, improve the safety of the tires on the road with compliance and maintenance reporting and alerts, and reduce technician time spent on tire-related maintenance and inspections,” said Revvo CEO Sunjay Dodani.

In an increasingly competitive environment where data is king, sitting on the sidelines is a risky gamble.

“We’re starting to get to the point where a lot of people are using technology and the databases and algorithms that drive that funneling of data down into actual insights has really improved,” Tindor said. “We’re moving into this phase where most data can produce an actual actionable insight for you. So now you can get on board and see a lot of productivity very rapidly.”

More actionable data is attracting more fleets according to Brian Cunningham, vice-president of fleet solutions at Bridgestone Commercial Solutions.

“It’s going fast,” Cunningham said. “Adoption is happening quicker and quicker every day.”

Getting started

Change at any level can be challenging but with the right approach a digital analytics tire management program can fit in nicely for a fleet and improve business for all concerned.

First up is communicating how the program will benefit the entire company explained Donna Murphy, initiative lead for connected pressure, services and solutions business line at Michelin North America.

“So you’ve made the decision to make this change digitally but does everybody in your organization know about the opportunities you’ve identified and why it’s needed?” Murphy asked during ATA’s tire analytics webinar. “Knowing about it is great. We know there’s a change coming and sometimes change is really a threat to people in our organization.

“But the why behind it … explain what the benefit is to the organization and them,” Murphy continued. “That may help us move forward in terms of getting to the success that we’re looking for. And when you’re looking at that, what are the operations that need to change and who will be impacted by it?”

Casing life and thus retread acceptance can get a leg-up with digital analytics according to Phil Mosier, Cooper Tire manager of commercial tire development.

Casing life and thus retread acceptance can get a leg-up with digital analytics according to Phil Mosier, Cooper Tire manager of commercial tire development.Hartoog recommended that prior to implementing a digital analytics program, fleets should identify their tire program’s current strengths as well as areas in need of improvement.

“Fleets should identify the maturity of their current tire management process by taking into consideration the individuals, the technicians, the managers —anyone who’s involved in the scope of tire management in the entire organization,” Hartoog said. “And they should evaluate the procedures that are involved step-by-step. Does this current state provide you with full visibility? Is it consistent every day? Is it consistent on every inspection? And is it consistent at every location? And lastly, does it measure your progress, or hold your team accountable if they’re not managing the tires correctly?”

Cunningham said it’s important that company leaders stay committed to the goals of the new analytics program.

“If there isn’t commitment from the top to continue following through on that and continue to discuss with the team how it’s working and what successes they are having, it slowly fades away and it’s just another thing that someone’s being asked to follow,” Cunningham said. “The word commitment is sometimes thrown around a little too easily. But if you have commitment from the top, and you have discussions from the top down, it normally sticks a lot better than if it’s just thrown out there.”

Murphy said beyond showing various departments how they stand to gain from an analytics program, be sure to be cognizant and responsive to reluctance.

“What’s the resistance level? How long does it take for them to buy into the idea of change?” Murphy said. “And that can be through different sorts of behavior. Maybe it’s a pizza party. Maybe it’s something as simple as a thank-you card. What are the ways that motivate your people to move toward that change? And be prepared to do that often to help move it through and to be aligned in the desire towards getting the devotion that we’re looking for.”

Data management

All the data in the world is no help unless the right data makes it to the right people.

When used with Goodyear’s Fleet Central, Goodyear’s CheckPoint, an automatic drive-over tire analytics tool, can quickly provide information on tread depth, air pressure and axle load.

When used with Goodyear’s Fleet Central, Goodyear’s CheckPoint, an automatic drive-over tire analytics tool, can quickly provide information on tread depth, air pressure and axle load.“First of all, is that data tire-related? If it’s not tire-related then it’s not geared towards what you’re trying to do with your tire program and it should be funneled out,” Cunningham explained. “That’s the first step with that. And the second step: how easy is it to get that data? Are your systems able to connect through an API—an application program interface—easily to other systems?

“The third point is very obvious,” Cunningham continued. “Now that we have data from tires, what do we do with that? Can we grade action off that? Has what we’ve created enabled us to take a look at what we’re doing and lower the overall cost of our tires? Those are three important areas that as you start to get into the data funneling section that you need to take a look at.”

When it comes to making sense of data, Tindor said it’s best to keep pain points in mind.

“Remember, you’re solving a pain point that really matters in your organization when you buy this technology,” he said. “Identify who needs to be involved in solving that pain point and then identify how they need to receive the information in order to activate that service. And once you know those two steps, now it’s time to either buy a solution or build a solution that integrates your tire management data and insights into that service activation system.”

Retreads rolling on

Getting the most of out of treadwear is one critical factor on the tire performance checklist. Casing life is another.

“For most fleet managers, the tread pattern and the cost of the tire are the main focus,” Mosier said. “But the casing should be a high consideration as well. It’s the core of the tire – the foundation – and what allows you to receive multiple retreads. It’s the true catalyst in lowering your overall cost of ownership. I always tell fleets to look at the tire, then look even closer at the foundation of the tire — the casing.”

A digital analytics tire management program can pave the way for that closer look.

“There is a very direct correlation between sound tire management and improved retread performance,” Remec said. “If a fleet chooses the right brand and tread designs for their specific application and vocation, this can extend tire and retread life. If a fleet implements a regular and thorough air pressure maintenance and tread depth management program, this can extend tire and retread life. It will also result in fewer casings being rejected for retreading, which further reduces a fleet’s annual tire spend.”