The focus of the new regulations is not on mitigating climate change, but rather on fuel economy. Industry experts say it makes sense to view the GHG regulations as a stealth move leading to the first fuel economy standards for heavy-duty and vocational diesel engines.

One possible approach to greater diesel engine efficiency is the use of waste heat recovery systems, a technology mentioned in EPA’s published GHG 2017 guidelines that outline credit programs for manufacturers. Among those credits is one “intended to promote implementation of advanced technologies such as hybrid powertrains, engines with Rankin cycle waste heat recovery systems, and electric or fuel cell vehicles.”

But what is a waste heat recovery system? How does it work? Is it viable for diesel truck engines?

A promising boost

Today’s diesel engines have a heat efficiency rating of about 44 percent – meaning that nearly half of the energy potential present in a gallon of fuel ends up in the flywheel as available power after the combustion process. The rest of that potential energy – the other roughly 56 percent – is lost.

“It comes out the combustion process as vaporized water and exhaust heat, although a certain balance goes into the cooling system to keep engine temperatures in check,” says Tony Greszler, vice president of government and industry relations for the Volvo Group.

The concept of waste heat recovery dates to the beginning of the Machine Age when steam engine designers realized the inefficiency of their creations. Steam engines work by heating water to create high-pressure steam that is pushed through a cylinder to create power.

The Peterbilt-Cummins SuperTruck team integrated a waste heat recovery system in two demonstration vehicles as part of its 50 percent efficient engine package, which involved Cummins’ ISX15 engine (below).

The Peterbilt-Cummins SuperTruck team integrated a waste heat recovery system in two demonstration vehicles as part of its 50 percent efficient engine package, which involved Cummins’ ISX15 engine (below).

Cummins has been at the forefront in developing waste heat recovery systems and has shown them to be a viable technology in laboratory demonstrations and truck installations, including the Cummins-led SuperTruck program funded by the U.S. Department of Energy.

Satish Chandra, the company’s director of advanced systems integration, says the SuperTruck – equipped with Cummins’ prototype waste heat recovery system and in 24-hour head-to-head testing against a 2009 baseline truck – demonstrated a 75 percent increase in fuel economy, a 43 percent reduction in GHG emissions and an 86 percent gain in freight efficiency.

“In Cummins’ experience, the technology is very attractive and viable when fully integrated in the vehicle system to boost fuel economy and support other energy needs such as driver comfort,” Chandra says.

Stede Granger, OEM technical manager for Shell Lubricants, says a waste heat recovery system and a hybrid drive system work in a similar fashion. When a hybrid vehicle’s brakes are applied, kinetic energy is captured by the onboard electrical motors. When the vehicle starts moving again, the electric motors use the captured energy for acceleration.

“That’s a highly efficient design, assuming you can design an economic and compact system to capture and reuse that energy,” Granger says.

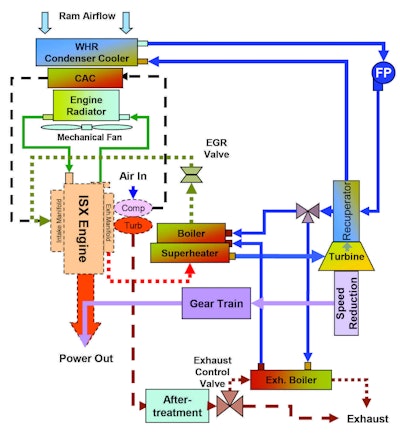

In most proposed waste heat recovery systems, the boilers are either the exhaust system or the exhaust gas recirculation system. If the waste heat recovery system is in the exhaust stream, it has to be behind the selective catalytic reduction system to work correctly.

“At that point, you have to connect the heat exchangers to some sort of expansion device,” Granger says – a turbine, a piston or any number of machines that can take pressurized gas and convert it to usable power. Once that process is complete, that power can be harnessed and sent to an electric generator to either run vehicle accessories or for gearing to convert it to mechanical power.

Over the last 20 years, waste heat recovery increasingly has been used in stationary applications such as power plants to boost efficiency and reduce greenhouse gas effects. Only recently has the technology been demonstrated in laboratory environments as a viable means to improve fuel economy in heavy trucks.

The Peterbilt-Cummins SuperTruck team integrated a waste heat recovery system in two demonstration vehicles as part of its 50 percent efficient engine package. “Waste heat recovery was a key contributor to the program results that achieved a peak 75 percent improvement in fuel economy over a baseline 2009 production truck,” says Ken Damon, manager of Peterbilt Motors’ vehicle performance group.

For vehicle applications, this approach has been investigated in laboratories for decades, and recent research and development has enabled implementation of functional prototypes on line-haul heavy trucks, says Mark Groeneweg, director of Daimler Trucks powertrain engineering for the company’s NAFTA region.

“Technology demonstrations facilitated by the U.S. Department of Energy SuperTruck program are a successful example of that,” Groeneweg says. “It is a promising technology to boost commercial vehicle fuel economy.”

One size won’t fit all

Despite the promise that waste heat recovery technology holds, there are significant barriers to implementing it in trucking applications.

“Kenworth and Paccar are constantly evaluating new technologies that provide benefit to customers,” says Kevin Baney, Kenworth chief engineer. “As engines continue to gain efficiency through measures such as downspeeding, reduced friction and parasitics, we also recognize the potential of waste heat recovery systems.”

But that potential, according to Baney, depends heavily on the engine’s duty cycle, and such systems also add cost, complexity and weight to the vehicle.

“When customers evaluate fuel-efficient features, they typically expect a payback of no more than two to three years that considers additional maintenance and upfront acquisition costs,” he says. “At present, we do not see an economically-based application for waste heat recovery in our vehicles, but we will continue to evaluate its viability.”

Greszler says waste heat recovery systems theoretically could provide fleets with up to a 4 percent boost in fuel economy – assuming they operate in the right applications. It’s more likely a vehicle would net only an overall increase of 2 percent because of lost aerodynamic efficiency, he says. “These are sizeable systems, and packaging will be problematic.”

The systems also present lag-time issues, Greszler says. Because it takes time for a waste heat recovery system to get fluids up to temperature, fleets running in mountains or hills won’t be able to access the additional power when they need it most – during the uphill portion of a climb. “It’s technology that will work best hauling heavy loads in flat terrain,” he says.

Weight also is an issue. “Our current estimates range from an additional 300 to 500 pounds,” Greszler says. “Maintenance demands will increase because it’s an entirely new system on the vehicle with lots of high-pressure plumbing and special lubrication demands.”

While Volvo thinks waste heat recovery technology potentially could be a useful option for some fleets, Greszler says the company also is concerned that it will be mandated by EPA as part of a future emissions or fuel economy regulation. “We don’t see it as a one-size-fits-all solution for fleets concerned about fuel economy,” he says.

However, Chandra says potential weight gains will be offset by reductions in the powertrain and elsewhere on future truck designs. For example, radiators potentially could be designed smaller due to lesser heat loads because the waste heat condenser would handle some of the cooling demands.

“If waste heat from EGR is used for waste heat recovery, the EGR cooler will be a new design,” Chandra says. “Other components are not likely to be affected. That’s why this is a technology that Cummins is still developing, testing and validating in applications, including our work on the SuperTruck program.”

The technology’s commercial viability will drive its future timing for production implementation, Chandra says. “There are also a number of optimization opportunities in aerodynamics and drivetrains that will provide fuel economy gains.”

Chandra says Cummins expects to deploy waste heat recovery technology in some fashion by 2020 or so, with some customers getting field test units in 2017 or 2018. “A version is being used in today’s Formula One racecars, where they add it to the standard V6 and call the package a hybrid,” Chandra says. “It recovers exhaust heat and turns it back into energy.”

Much engineering work remains for waste heat recovery technology to yield a positive business case, which involves the system’s cost, its fuel savings potential and fuel cost itself, Groeneweg says. More development is required to reduce cost, improve over-the-road performance and manage the complexities related to numerous vehicle integration tradeoffs, including weight, packaging, radiator sizes and aerodynamic penalties.

“The reliability and durability of this relatively complex system needs to be ensured before the product is ready for real-world commercial use,” he says. “That’s why current waste heat recovery systems are only on research and development prototype demonstrators.”