ZF also says it now has an AS Tronic configuration for every commercial vehicle variant — whether it be delivery traffic or long-distance traffic, coach, construction equipment or a rail vehicle.

How the AS Tronic operates

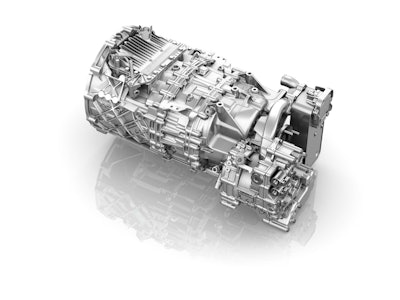

While the driver had to preselect gears manually on the early semiautomatic AS Tronic transmission, the second generation of the transmission launched in 2000 relieved the driver of the need to change gear: Automatic gear selection and electronically controlled gear changes reduce the strain on the driveline, thus increasing the service life of the driveline components. By networking transmission electronics and engine management via the CAN bus, the gearshift strategy used by the ZF-AS Tronic always ensures the engine operates in the optimum speed range. In this way, the power is transmitted efficiently – thereby saving fuel – to the drive axles.

Successor ready and waiting

Coinciding with the production milestone of the AS Tronic, ZF is readying its next AMT: TraXon, the modular automatic transmission system, which will be produced at the ZF location in Friedrichshafen and will gradually replace the AS Tronic over the next few years.

The all-new basic transmission is suitable for torque requirements of up to 3,500 Nm and can be linked to five modules. The new system features an anticipatory shifting strategy courtesy of PreVision GPS. ZF thus gives truck manufacturers the opportunity to link up the transmission with GPS data and digital map material. In this way, unnecessary gearshifts can be avoided – for example when a conventional transmission control unit shifts up a gear before an uphill gradient or a narrow bend, just to shift down to a lower gear shortly after.