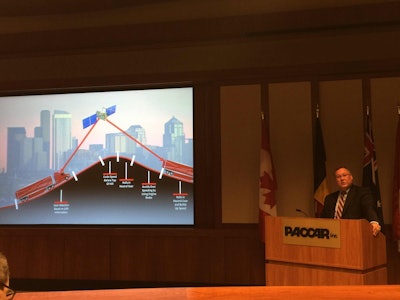

Robert Woodall, Peterbilt’s assistant general manager for sales and marketing, shows how Peterbilt’s adaptive cruise control works.

Robert Woodall, Peterbilt’s assistant general manager for sales and marketing, shows how Peterbilt’s adaptive cruise control works.Drivers of trucking innovation are many times drivers of the equipment itself.

Speaking at a Technology Showcase held Thursday at Peterbilt’s Denton, Texas truck plant, Peterbilt executives say they most often solicit the opinions of drivers as they look to push the technological envelope with the company’s trucks.

Andy Weiblen, Peterbilt’s director of product planning, says the company’s design process goes through several steps including a market needs analysis, ideation, concept, validation and final design process.

Customer councils help drive the market needs analysis.

“Also, we conduct field analysis at truck stops,” Weiblen says. “And we used this method to help design cab size of model 579 and 567.”

Ideation takes the process of listening to the driver to the next level.

“We not only look at what they say,” Weiblen says, “but we watch what they do.”

Driver behaviors, like watching drivers use a dash mounted cup holder to hold a cell phone, helped guide Peterbilt to develop an interior design that built a place to charge and store a phone into the blueprint.

The truck concept is then surfaced in 3D, which allows the company to look at aesthetics and aerodynamics.

“Performing these tests early allows us to achieve the best possible outcome,” Weiblen says.

Robert Woodall, Peterbilt’s assistant general manager for sales and marketing, says a common theme in the company’s new product announcements has been technology.

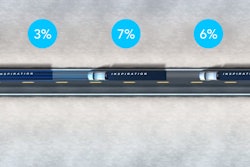

For example, he says Peterbilt’s predictive cruise control uses GPS data to ensure the engine and transmission are operating in most efficient mode based on terrain data. This feature will be available on the Model 579 and Model 576 this summer.

In order to produce a more technologically advanced truck, Peterbilt’s Denton plant had to undergo extensive upgrades.

The company increased its assembly automation and is in the process of adding build capacity.

Also added was a non-contact laser alignment feature, which ensures the truck is as straight as possible at the conclusion of production. The Denton facility is the first assembly plant in the U.S. to have such a feature.

“Innovation does not stop at the truck, we also focus on technologies beyond the cab,” says Scott Newhouse, Peterbilt chief engineer. Autonomous technologies like lane keeping, traffic assist, GPS navigation and platooning are all constantly being evaluated, he said.

“The technology is not the issue,” says Darrin Siver, Peterbilt general manger, of the proliferation of autonomous technologies in trucking. “It’s governmental regulations and those type things. The technology is ready. It’s here.”

Woodall notes there’s clearly been a shift toward automated transmission with Peterbilt now spec’ing 30-plus percent AMTs in new trucks over the past 12 months.

“And it’s climbing strong,” he says.