I was able to take Stoneridge’s MirrorEye system, outfitted on a 2019 Freightliner Cascadia, around the Metro Detroit area.

I was able to take Stoneridge’s MirrorEye system, outfitted on a 2019 Freightliner Cascadia, around the Metro Detroit area.As advanced as new trucks have become, some of the pieces remain fairly basic and largely untouched by modernization. In the early 1900s, mirrors were an option, and it wasn’t until the 1970s that passenger side mirrors became standard. About a decade later, they became powered, but in the 40 years since, there hasn’t been a lot of energy put into innovation. Until recently.

Enacted in 2014, Greenhouse Gas (GHG) Phase 1 dictated that trucks, by model year 2017, achieve a 7%-20% reduction in carbon dioxide (CO2) emissions over MY 2010 baselines. Now, GHG Phase 2 calls for, by MY 2021, a 15%-25% reduction over 2017. To-date, engine manufacturers have done most of the heavy lifting to boost efficiency, but much of that low-hanging fruit has been picked, making aerodynamics and drag coefficients more important than ever.

Mirrors are responsible for approximately 2% of the aerodynamic drag created by a tractor, but federal regulations that require “two rear-vision mirrors, one at each side, firmly attached to the outside of the motor vehicle” haven’t left a lot of room for breakthroughs. That regulation did, however, leave Novi, Mich.-based Stoneridge – a designer and manufacturer of engineered electronic systems for safety and security, vehicle intelligence efficiency and emissions – enough room for interpretation.

A leap forward in looking backward

The exterior camera arm can be folded inward by pushing a button inside the cab, and it also has a breakaway feature. In the event of an impact, it automatically closes to protect itself.

The exterior camera arm can be folded inward by pushing a button inside the cab, and it also has a breakaway feature. In the event of an impact, it automatically closes to protect itself.Stoneridge’s MirrorEye Camera Monitor System replaces a truck’s conventional mirrors with integrated external digital cameras mounted outside above the cab and digital monitors inside. The MirrorEye system includes five cameras, sensors and three high-definition digital display screens.

The camera housing’s design helps keep it clean by creating a vacuum at the lens. In the off-chance that rain or mud splashes onto the lens, the vortex created by aerodynamics helps remove it. Heavy soiling can be removed with a towel or a blast of water. The lens is heated to prevent icing.

Independent video processing of multiple camera images offers a form of redundancy by ensuring that in the unlikely event an individual camera fails, the other real-time camera images will be displayed continuously without interruption.

Stoneridge has received an exemption from the Federal Motor Carrier Safety Administration (FMCSA) to operate trucks without standard external mirrors.

The company’s next-generation “mirrors” are a pair of monitors affixed to the A-pillars and a smaller display mounted to the center of the windshield that acts as the look-down blind-spot mirror. The look-down display is located where a rearview mirror would be on a passenger car — a position that was finalized through field-trial driver feedback. Since most collision-mitigation and lane-keeping sensors already are mounted in this position, it allows for an intuitive placement without the screen obstructing the driver’s view out of the windshield.

Stoneridge claims MirrorEye improves a driver’s field of view and eliminates common blind spots, but the kicker is an estimated up-to-3% improvement in fuel economy due to taking the mirrors off the truck and replacing them with the wing-like cameras.

Five fields of view across three monitor positions

I was able to take the system, outfitted in a 2019 Freightliner Cascadia, around the Metro Detroit area, and it didn’t take long to adjust to the subtle change in the driving environment. The driver’s-side 12.3-inch monitor is fairly close to your face compared to a conventional mirror, but you barely notice it after a few seconds. A larger 15-inch monitor acts as the passenger-side mirror. The rear-facing cameras are mounted high above both doors, each providing normal and wide-angle views. The look-down view comes from the passenger-side camera.

I rarely use a look-down mirror. They usually vibrate so violently mounted atop the door that you can barely see out of them, but it was a pleasant change to see the static and clear view the few times I did glance up at the screen.

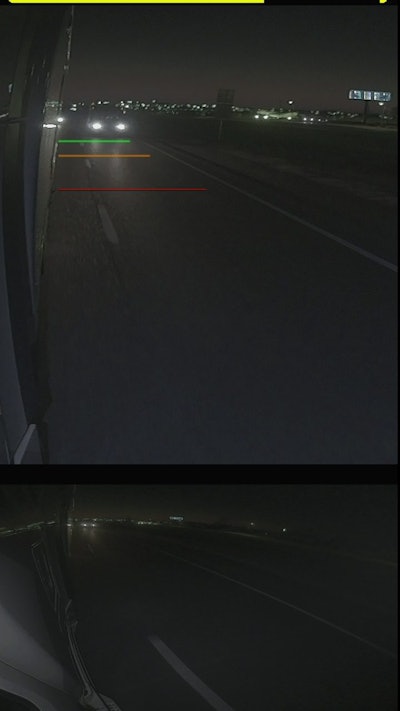

Distance markers in the monitor show the end of the trailer, 40 feet behind the trailer and 80 feet behind.

Distance markers in the monitor show the end of the trailer, 40 feet behind the trailer and 80 feet behind.There are distance markers in the side monitor that show the end of the trailer (red), 40 feet behind the trailer’s end (orange) and 80 feet behind the end (green).

As part of a pre-trip, a driver uses a stationary object to set the red end-of-trailer line using a dial in the video display controller. The system automatically calculates the other two distances in 40-foot increments.

Those red, orange and green lines indicate, at a quick glimpse, whether or not it’s safe to change lanes. There’s a bit of finesse needed here in that you still have to account for the closing speed of vehicles beyond the green as they creep closer to the orange and red. While you could change lanes safely when a vehicle is behind the green indicator, you could be cutting that driver off by the time you complete the maneuver. You also have to do this with standard mirrors, but with the camera system, I had to remind myself to weigh all the other variables and that green doesn’t simply mean “go.” After 10 to 15 minutes and a few lane changes, you get the feel for it.

There was a trust period with this setup. The longer I used it, the more I embraced what it was telling me. Only a few miles in – after maybe 30 minutes – I had forgotten the purpose of my test drive. The monitors simply had become my mirrors, and the baked-in safety improvements, including the distance markers, quickly became intuitive.

Your field of view is wider in the monitor than with a traditional mirror, but that didn’t stop me from rocking back and forth in my seat to try and broaden it like you would with a mirror. After about an hour, you have to laugh at yourself and wait for your muscle memory to forget. If you actually need a wider view, you can pan the camera manually with the dial in the video display controller. In most cases, the screen provides you with a field of view that is more than enough.

The camera will pan automatically when following the trailer in a turn, which allows the driver to see and track the trailer tires at all times. This especially was handy navigating several unexpected roundabouts where an over- or under-steer could mean the difference in hitting a curb or the trailer leaving its lane. Being able to see the tires through the occasionally deep S-turns made maneuvering safer and more precise. It also makes deep turns at intersections – namely dodging curbs, road signs and cars that pull too far up into the lane – much easier because the camera gives you a better perspective and clearer view of what is happening at the end of the trailer.

Infrared makes the display amazingly clear and crisp without any glare from oncoming headlights.

Infrared makes the display amazingly clear and crisp without any glare from oncoming headlights.The system performs as good or better than mirrors during the day, but at night, the camera system is exponentially superior. There’s no “military night vision goggle” green tint — the use of infrared makes the display amazingly clear and crisp, and there’s no glare from oncoming headlights. Thanks to infrared, the road immediately behind the truck is lit better than with just a mirror, making monitoring trailer off-tracking and lane dividers that much easier.

My opportunity to back the rig was fairly limited, and that probably was a good thing. Admittedly, it was difficult for me. I turned a normally simple offset back into a parking spot into quite an embarrassing exercise. I struggled to accurately determine the distance between the trailer’s left side and the curb I was attempting to back against, which resulted in my rig not being as straight as it appeared and consistently being further from the curb than I thought I was. I was able to slide the truck and trailer where I needed it to go – eventually – but it wasn’t pretty. With a little more time behind the screen, I think I would have gotten the hang of it.

I was skeptical of the platform originally, but not as a technology. It is clearly viable. The Technology and Maintenance Council’s S.4 Cab & Controls study group has started development of an engineering recommended practice (RP) for the conversion of rearview mirrors to camera monitoring systems, a task force that is chaired by Stephen Fox, vice president of business development for Stoneridge.

MirrorEye has been installed with more than a dozen fleets and logged millions of miles with the likes of Maverick Transportation (CCJ Top 250, No. 75), J.B. Hunt (No. 3) and Schneider National (No. 7). Tyson Foods is rolling out one of Stoneridge’s largest commercial install programs for its rearview camera system, deploying about 50 trucks that will evaluate the platform’s safety performance over the next several months. Down the line, the company will work with drivers to remove traditional mirrors completely and start gathering information on potential aerodynamic and fuel efficiency improvements.

I had no doubt the system would do exactly what it was designed to do. My cynicism was in its practicality. Was this really a better mousetrap, or is this a techie digital solution in search of a problem? After my drive, my belief is that while traditional and simplistic mirrors do a pretty good job of informing drivers about their surroundings, the MirrorEye system takes that to a new level by elevating “a pretty good job” to “excellent.”

In FMCSA’s decision to grant the waiver, the agency said the system eliminates blind spots on both sides of the truck and expands field-of-view by an estimated 25%. If the system prevents just one side impact, it more than pays for itself, and the fuel economy savings – which at 3% over 100,000 miles could be about $1,300 per year – are just icing on the cake.