Mitsubishi Electric Automotive America (MEAA) is rolling out a new platform that aims to eventually broaden autonomy on streets and highways.

The HubPilot autonomous distribution yard logistics platform as a service, which will be fully operational in 2025, is currently designed for geofenced distribution centers and logistics hubs but has the potential to be used for on-road applications for autonomous vehicles in the future.

“Distribution centers is our first application. The technology can be applied to seaports, airports, large manufacturing facilities and distribution centers and, in the future, complicated on-road applications,” said Mark Rakoski, vice president of advanced engineering at MEAA. “Broader autonomy is on-road applications for autonomous vehicles and or to address safety needs such as complicated intersections where drivers and pedestrians are vulnerable.”

The platform uses a combination of software, on-vehicle sensing and infrastructure-based perception with high-definition mapping for precise localization.

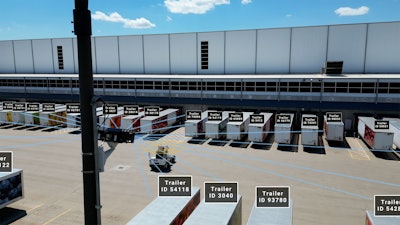

With optimized multi-sensor inputs on autonomous yard dogs – also known as rovers or terminal tractors – combined with advanced software, the platform can visualize the yard dogs’ surroundings, identify assigned trailers and confirm their locations. Trailers are virtually “tagged” so the platform can track their location and movements in real time. The platform interfaces with the yard management system to receive commands, operating at SAE Level 4 autonomy, wherein the vehicle is completely responsible for all driving and navigational tasks. The platform also automates the connection of compressed air hoses to the trailer to operate the air brakes, eliminating the need for manual intervention each time a yard dog picks up or drops off a trailer, though yard dogs can still be operated manually by a driver.

“Utilizing real-time data and visualization, the yard dogs autonomously connect with trailers and transport them to designated locations, all while maintaining constant awareness of their surroundings to avoid contact with stationary and moving objects, including people,” said MEAA Director of Mobility Eyad Zeino.

LIDAR sensors are also placed on yard infrastructure like buildings or poles, rather than solely on the vehicles, which enables the platform to eliminate those blind spots.

Rakoski said this increases safety in the yard. It also increases security as the platform provides 24/7 monitoring, reducing opportunities for theft and vandalism. The platform is also secure in terms of cybersecurity as measures have been taken to prevent hackers or other outside sources from interfering with the technology.

Rakoski added that it also enables greater efficiency, while helping with driver and staff shortages.

“Due to our 24/7 monitoring aspect of the platform, HubPilot can support scarce labor challenges for yard assets, gate check-in and check-out,” he said.

Rakoski said humans are still needed for logistics management.

MEAA will continue developing the platform throughout the remainder of the year before fully launching next year.

“We are finishing our MVP (Minimum Viable Product) phase and continuing our testing and validation in real application, simulation and controlled environment scenarios,” Rakoski said. “We will move to the production phase in 2025 at an initial site and are looking to begin deployment on other sites in 2025, as well.”