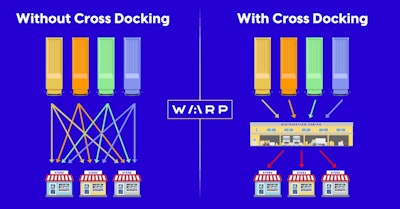

Hub and spoke transportation is arguably the most efficient method in the supply chain, said WARP Co-founder and CEO Daniel Sokolovsky. Despite that, many shippers shy away from using such a network because of cross docking that often results in loss of freight visibility as it moves from one carrier to another or through a cross-dock facility, leaving shippers to manually track where their freight is with phone calls and paper trails.

Sokolovsky said that’s why WARP developed technology-backed cross docks that digitize the traditional hub and spoke freight network.

With WARP Stations, all cross docks in the network are provided with software available on mobile and desktop devices and hardware, including a zebra scanner and printer, that digitizes the manual processes of freight transfers with real-time tracking of vehicles as well as freight as it's scanned into a facility, loaded onto a truck and exits the facility for its destination.

“It's been a fragmented, disconnected model,” he said. But with WARP Stations, “it's actually like an inventory management system; the technology tracks the different pieces of inventory that are moving through our network and understands exactly where those different things are.

“Then also we have mapping within the building, so we know exactly where inside of that building the freight is,” he added. “We've built out scanning capabilities; we’ve built out being able to integrate with a dimensionalizer.”

[Related: CLI launches new routing logic and planning optimization solution]

WARP’s technology weaves together carriers and cross docks to give shippers real-time access to their freight for the entirety of the journey down to a piece-level.

“Basically, we break these transactions or the shipments up into different pieces, and then we optimize each and every little piece on its own,” Sokolovsky said.

When a shipment enters the WARP system, it builds a route for a local driver, who uses the WARP app to track each step of that route. Once the freight arrives at the cross-dock facility – via a cargo van or a box truck, for example – it is scanned, and tracking switches from live GPS to warehouse mapping until it is picked up by, say a 53-foot truck, which WARP plugs into their ELD for tracking for the next stage of the shipping process.

With a goal of collaboration and open-source logistics as the future of freight, WARP is sharing exactly how its new technology works step by step:

Step 1: Once the route has been created digitally in the WARP system, a label is printed for each pallet or piece based on the shipper’s speed and price preferences. When the driver arrives to pick up the freight, they can opt to be geofenced into the pick-up location and cannot begin their route until each pallet or piece assigned to their route has been scanned.

Step 2: When the driver arrives at the WARP Station, the BOL is signed by both them and the cross-dock operator in WARP’s driver app, showing that the drop-off has been completed. Shippers have access to the location of the truck at all times through WARP’s DirecTrack technology so they can see via GPS when the truck has arrived.

Step 3: The WARP Station staff scans every pallet or piece from the freight shipment, and WARP’s algorithm determines whether an updated shipping label is needed or if the pallet needs to be disassembled. It also gives staff the physical position of where the freight should be staged at the cross dock based on the dock door it will be loaded out of.

Step 4: The next carrier in WARP’s network will arrive the same or next day to pick up the freight. The WARP Station staff will scan out each pallet or piece as it’s loaded onto the outbound vehicle, and both the driver and staff sign the BOL after the vehicle is loaded.

Step 5: When the driver arrives at the next destination, they sign another BOL that marks the route completed. Shippers can also see the truck’s progress to the destination in real-time through WARP’s platform.