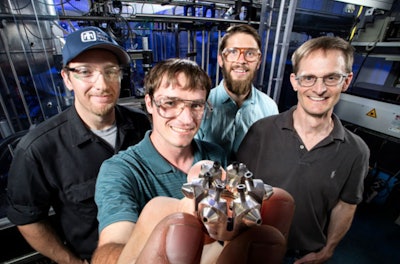

From left: Sandia Lab researchers Nathan Harry, Christopher Nilsen, Drummond Biles and Charles Mueller show a patented ducted fuel injection module. (Photo courtesy of Sandia National Laboratories.)

From left: Sandia Lab researchers Nathan Harry, Christopher Nilsen, Drummond Biles and Charles Mueller show a patented ducted fuel injection module. (Photo courtesy of Sandia National Laboratories.)A prominent science magazine whose storied archives include articles from Albert Einstein recently wrote about new diesel technology which has been shown to drastically reduce soot.

The December edition of Scientific American features a story on a patented ducted fuel injection (DFI) system which has demonstrated soot particle reduction rates of 50 to 100 percent.

Combustion scientist Charles Mueller, who works at Sandia National Laboratories, has patented his Bunsen burner like technology which has attracted support from Ford, Caterpillar, Toyota and Georgia Tech.

Mueller’s device introduces more air into diesel injectors which makes for a more thorough burn and thus produces far less soot. His idea hails from the humble, but effective Bunsen burner.

“He saw that by equipping diesel fuel injectors with tiny Bunsen–burner-chimney equivalents—small metal tubes installed a short distance from the injector nozzle hole and aligned with the fuel stream—fuel and air could be more fully premixed to enable that even, soot-free, blue-flame burning,” writes Scientific American staff editor Steven Ashley. “And it could happen at the lower temperatures required for anti-NOx dilution.”

In a Sandia Lab News story titled ‘Diesel Engine Revolution,’ Mueller explains how oxygenated, renewable diesel fuels used in a DFI system could further lower emissions and lead to a reduction of heavy and costly after-treatment exhaust components.

“Using oxygenated fuels with DFI lowers emissions more than DFI with conventional diesel fuel, perhaps enough to enable a less-expensive engine system because less exhaust after-treatment would be required,” Mueller says.

“On a modern on-highway truck, after-treatment amounts to about $12,000 in initial and operating costs over the life of the vehicle. Reducing even a fraction of those costs is a big deal, given the large number of these vehicles and their importance to the economy.”

Conventional diesel engine injectors produce 3-10 times more fuel than required for combustion, Mueller says.

“When you have that much excess fuel at high temperature, you tend to produce a lot of soot,” he says. “Installing the ducts enables us to closely approach what we call ‘leaner lifted-flame combustion’ — diesel combustion that doesn’t form soot — because the local mixtures contain less excess fuel.”

Ford and Caterpillar have recently signed cooperative research and development agreements with Sandia to help advance DFI technology.

As far as the push for new green technology is concerned, Ashley says that the diesel engine has a lot of job security.

“Green replacements, based on electrochemical batteries and hydrogen fuel cells, for example, do not yet have the juice to replace diesel as a critical power source in the global economy,” Ashley states. “Diesel engines are robust, durable, fuel-efficient and, crucially, can provide the big torque needed to move big things. Most of the hundreds of millions of medium and large long-haul trucks on highways today run on diesel—as do majorities of the world’s trains, ships, off-road vehicles and heavy machinery, not to mention many electricity generators, domestic pickup trucks and European passenger cars.”