A container ship Tuesday morning slammed into Francis Scott Key Bridge in Baltimore, a major bridge just outside of Washington D.C., snapping it into pieces and plunging the wreckage and several vehicles into the Patapsco River below.

Clearance tech will be especially important for motor carriers that are regular users of the Francis Scott Key Bridge. The Port of Baltimore is closed to ship traffic but the port is still processing trucks. Motor carriers have long known the risks that come with an over-height truck or a low-clearance bridge. Low-bridge collisions are not uncommon; in fact, the Federal Motor Carrier Safety Administration considers bridge strikes a serious safety hazard.

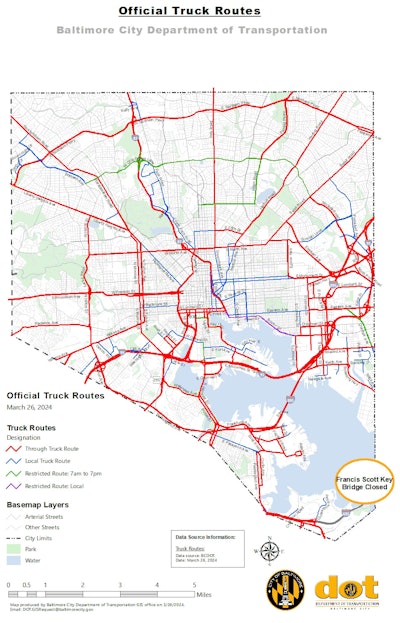

Harbor crossing alternate routes will be Interstate 95 or I-895 tunnels, but vehicles transporting hazardous materials, including propane over 10 pounds, are prohibited in tunnels and should use the western section of I-695 around the tunnels, according to the Maryland Transportation Authority.

Vehicles in excess of 13'6" in height or 96" in width are prohibited from using the I-895 Baltimore Harbor Tunnel.

The I-695 Outer Loop is closed at MD 10 (exit 2) and Inner Loop is closed at MD 157/Peninsula Exp (exit 43). Use I-95 or I-895 alt routes.

The Interstate-95 Fort McHenry Tunnel height is 14’6” and 11’ wide.

In New York State, which is home to some of the lowest bridges in the nation, 344 low-bridge collisions occurred in 2021, according to the New York Department of Transportation and Thruway Authority; in 2022, 67 bridge strikes occurred across New York City’s boroughs alone, according to information from the City of New York’s Bridge Strike Data.

[Related: Here’s how to minimize risks of GPS routing]

Bridge strikes can result in injury or loss of life at worst and damages to infrastructure, interruption of commerce and delays in travel times at least, not to mention the impact such a crash has on a trucking company: costs related to infrastructure, equipment and cargo damages and insurance premiums, the potential loss of a driver and damages to reputation.

While it doesn’t collect statistics on the matter, the FMCSA believes bridge strikes are avoidable. That has been proven with the use of different technologies.

“Safety is essential. You don't want to be crashing into anything ever. That's at the top of the list of why it's important. Beyond that is just about pure efficiency,” said Chris Oliver, chief marketing officer at Trucker Path. “If you're routed incorrectly and recognize the truck is too tall to go under a clearance, I'm glad you recognize that and there wasn't a crash. But then you have to figure out how to turn around and take that truck the opposite direction and find a new route. There's a lot of time to be wasted there. By being able to know with confidence that you're avoiding those, you get from point A to point B much more quickly.”

Navigation is a big chunk of what drivers use the Trucker Path app for. The app, which also allows drivers to input their vehicle specs like height, weight and weight limit, uses Here Technologies, which provides the initial feed of bridge heights and low clearances.

“If you say you've got a truck that's 15 feet tall, and you need to go from point A to point B, we make sure that we don't route you under any clearances below 15 feet. That's how it works on the surface; that's straightforward,” said Oliver. “The bad news of that is it's never perfect. So inevitably, at some point, that's not going to work, and it'll be a lower clearance than expected. Could be old bridges where the data is outdated. A bridge used to be 15 feet high, but after a handful of repairs, it’s now 14.5. Things just happen and change over time.

“So what we do is we give the users the ability to give us that feedback,” he said. “That then goes back into our database so that we know that even though our initial data feed said that bridge was 16 feet, we've had users who tell us it's only 14. So then we stop routing people there that are over 14 feet.”

GiraffeG4 Systems also collects that data but via sensor instead of crowdsourcing.

The company offers its Sentinel product, a low-clearance collision avoidance system that leverages a sensor to help large trucks and RVs steer clear of low bridges.

It provides warnings to drivers via mobile app in which the driver inputs the height of the vehicle and trailer ahead of embarking on a trip. The app interacts with the GPS system the driver is using to pre-measure heights based on the GPS’s information.

But that information isn’t always correct, said Frank Nugent, president of GiraffeG4, so the sensor measures the exact height of an obstacle a vehicle is about to pass under and continues to measure the height of the obstacle until the vehicle is safely clear. That data is then automatically entered into the GiraffeG4 database to warn other drivers that take the same route.

FMCSA advises fleets to use GPS navigation systems designed specifically for large trucks to help avoid low clearances. But Oliver said a lot of fleets, especially small operators, use systems like Google Maps that are primarily for passenger cars. While it can route a driver efficiently in terms of time and distance, it doesn’t account for weight limits or bridge heights.

E-SMART is another system designed for fleets with large trucks that takes things a step beyond in-cab alerts and actually slows a truck. Fleets that have integrated E-SMART have experienced a complete elimination of low-clearance bridge hits, according to its users.

E-SMART is a speed limiter that uses advanced position systems technology to determine vehicle location to actively manage its maximum allowed speed, provide real-time safety alerts, and identify known hazard areas such as low clearance bridges.

While low-clearance avoidance isn’t its primary function, E-SMART has saved Arnold Transportation Services on multiple occasions, said Wes Bement, risk manager at the Grand Grand Prairie, Texas, carrier. After experiencing bridge strikes costing about $6,000 each, Arnold Transportation Services has had a 100% reduction in low bridge collision events since installing the E-SMART solution across its entire fleet.

“E-SMART has gone in and manually geofenced low bridges that are on routes that are accessible to trucks,” Bement said. “So if our truck crosses that imaginary geofence line, then the system starts taking away the engine’s ability to make power until the truck is safely stopped before it ever gets to that low bridge.”

Nugent said with today's technologies, there is no reason drivers should ever again have to perform a "bump-and-run" where they pull up to a low obstacle very slowly to determine if they can clear it.

Prior to using E-SMART, Navajo Express experienced an average of six bridge strikes per year at an average cost of $18,277. After installing E-SMART three years ago, the company also has seen a 100% reduction in low bridge collisions resulting in an overall savings of $328,986.