The following was published in CCJ's Equipment Maintenance Toolkit, 8th edition, sponsored by Valvoline Heavy Duty. CCJ's Equipment Maintenance Toolkit is a complementary industry resource, courtesy of our partnership with Valvoline Heavy Duty. You can download the entire Toolkit here.

Implementing a tire test can help fleets save plenty of money over the long-haul but there’s plenty of work to be done in order to do it properly.

If there’s consistency with testing and data gathering practices then a fleet might just reach a eureka moment.

That was the case for The PIT Group, a brand-neutral testing group in Canada that helps manufacturers and fleets to hone-in on the best performing truck products like tires, which rank as the second highest expense for fleets behind fuel. Tire tests at PIT have become particularly popular especially where fuel economy is concerned.

“We have reached up to 5% fuel economy difference between two brands of the same type of tire,” said Marc Trudeau, senior member relation and business development specialist at PIT Group. “The price difference between these two tires was only roughly 10%. If you’re going to pay $8,000 to put tires all around on your tractor and trailer that will save $15,000 in fuel, it makes no sense to get the cheapest tire.”

Improved fuel economy and tread life can motivate fleets to pursue tire tests of their own, but it’s far from easy and will require plenty of thought, the right equipment, cooperation and, of course, cost.

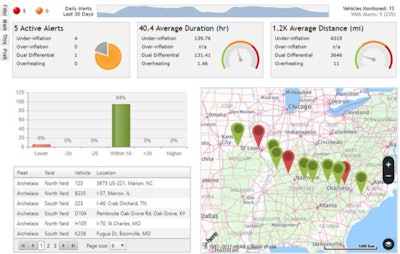

A tire testing program can be used in conjunction with a tire monitoring program like TireStamp’s maintenance dashboard offered through the TireVigil Cloud.

A tire testing program can be used in conjunction with a tire monitoring program like TireStamp’s maintenance dashboard offered through the TireVigil Cloud.“Tire tests cost time and money to run, and they are not easy to do correctly,” said TireStamp President Peggy Fisher. “It requires a great deal of concerted effort for many fleets simply to find the vehicles with the test tires. Then it demands considerable labor to take tire tread depth measurements and to record the findings.”

Fisher cautions that tire data collecting and recording requires careful consistency that may prove too tedious for the average tech. Next comes critical number crunching, which reveals the tires that rank better over others in the test.

“Someone has to analyze the data and compute the results,” Fisher continued. “Fleets have to determine if they have the personnel, commitment and determination to set up a tire test correctly, will have access to the test tires at regular intervals and can conduct tire tests properly for what could be a year or more.”

Team commitment is vital, but it won’t get far without the right equipment.

“Tire wear rates can vary greatly with vehicle type, make and model. Therefore, it is imperative that a fleet have adequate equipment for in-house testing,” said Roger Best, market insights and product applications engineer at Bridgestone Americas.

When testing equipment, Best recommends using the following guidelines: use the same vehicles for all testing groups, if possible; if a fleet is unable to use the same vehicles for testing, ensure they are evenly represented in each group; and if possible, use new vehicles.

“A second consideration is to ensure the fleet has enough equipment to perform the test to get repeatable and statistically significant data,” Best continued. “Each tire should be uniquely identified (branded, if possible) prior to testing.”

Timing is important given all the variables that can affect tire performance.

“Tires should be installed in the same time period to eliminate any differences due to weather and attempt to ensure that all tires can be compared at roughly similar states of wear,” said Pat Keating, Yokohama senior manager of field engineering.

Fleets that have struggled with maintenance records may want to reconsider taking on their own tire test.

“Any fleet who buys tires is a good candidate for in-house tire testing, but it is helpful if the fleet is already keeping good maintenance records,” said Marco Rabe, Continental Tire’s head of research and development for truck tires in the Americas.

Digital tire monitoring solutions, like Continental’s ContiConnect platform shown above, “offers fleets access to all their tire data at a glance, and helps track several variables for an accurate comparison,” said Marco Rabe, Continental Tire’s head of R&D for truck tires in the Americas. “But visual inspection of the tires is still important, especially during the testing phase, to check for irregular wear, stone drilling, and other concerns.”

Digital tire monitoring solutions, like Continental’s ContiConnect platform shown above, “offers fleets access to all their tire data at a glance, and helps track several variables for an accurate comparison,” said Marco Rabe, Continental Tire’s head of R&D for truck tires in the Americas. “But visual inspection of the tires is still important, especially during the testing phase, to check for irregular wear, stone drilling, and other concerns.”“The practice of collecting and recording tire data is crucial for a successful test,” Rabe said. “A minimum number of test vehicles under similar conditions is also important for a statistically relevant test result. Digital tire monitoring solutions, like Continental’s ContiConnect platform, offers fleets access to all their tire data at a glance, and helps track several variables for an accurate comparison. But visual inspection of the tires is still important, especially during the testing phase, to check for irregular wear, stone drilling and other concerns.”

Trudeau strongly recommends alleviating some of the burden on techs to keep up with tire testing by investing in tire tracking chip technology “with Bluetooth or WiFi that can recognize where the tire is and where it’s been working and for how long.”

Challenges aside, Phil Mosier, manager of commercial tire development for Cooper Tire & Rubber Company wrote in an article posted on the company’s website that “the best way to determine what’s best for your operation” is to conduct ongoing, in-house tire testing.

“Granted, it’s not easy,” Mosier said. “You have to track tires and take tread measurements; you have to maintain excellent maintenance practices to ensure inflation levels are correct, and that alignments stay true. And, to get results that will give you accurate information, you need to run the test tires for long haul operations to 50% to 60% of their wearable tread depth.”

Keating also supports fleet tire testing not only because of the unique driving conditions carriers can face but also for the long-term best practices that such testing promotes.

“All major tire manufacturers test new products extensively before launching them, but there is no substitute for generating performance data under a fleet’s own specific conditions,” Keating said. “A secondary benefit is that in-house testing reinforces good habits for monitoring cost-per-mile on all of the fleet’s tires.”

Before the rubber meets the road

As with any valid test, certain steps need to be employed to render dependable results. The same holds true for tire testing where variables can range far and wide. However, thought it might be tempting, don’t take on too many variables at once.

“It is important to test only one variable at a time such as one brand tire versus another brand of the same type/vocation tire,” Fisher said. “No matter what is being tested, in all cases the fleet must run two samples of tires: the test group versus a control group or another test group. A real test is not just throwing a few tires on a vehicle and seeing what they’ll do.”

Using the right number of tires for testing will deliver statistically significant results that a fleet can lean on for sound tire buying decisions.

“To get repeatable results, there should be at least 30 tires of each test group at the end of the test. Assume some tires may be removed and lost during the test period,” Fisher continued. “A fleet can get by with smaller samples, which may provide useful data that indicate differences in the groups of tires in the test, but the results may not be repeatable. My advice is to use as many tires as possible in each test group if an ending number of 30 is out of the question.”

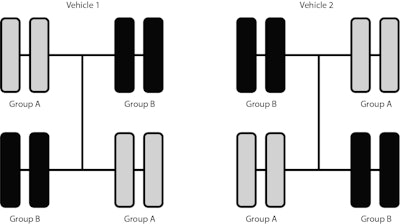

Phil Mosier, manager of Cooper Tire’s commercial tire development, said that two brands of tires can be tested on one truck. “As for drive tires, you can test two brands of tires on one vehicle. The only caveat is that their diameters need to be within ¼-inch of each other,” he said. “With this evaluation, you can run two trucks with eight wheel positions. The key is doing an X-pattern (or cross-axle) on the two rear axles.”

Phil Mosier, manager of Cooper Tire’s commercial tire development, said that two brands of tires can be tested on one truck. “As for drive tires, you can test two brands of tires on one vehicle. The only caveat is that their diameters need to be within ¼-inch of each other,” he said. “With this evaluation, you can run two trucks with eight wheel positions. The key is doing an X-pattern (or cross-axle) on the two rear axles.”Rabe also said more is better when it comes to tire testing.

“Increasing the number of trucks and tires tracked will help to account for some driver influence and for those variables that cannot be controlled,” Rabe said. “The statistical deviation in the test results will indicate the level of confidence in the test results.”

When it comes to establishing the parameters of a test tire program, including test duration and scope, Rabe said “getting buy-in from the shop managers, maintenance workers, tire program managers and drivers is crucial.”

To get dependable results, testing conditions should be as uniform as possible.

“It is important to select comparable conditions for an accurate head-to-head comparison,” Rabe said. “This means similar trucks, similar routes, starting the test at the same time to account for weather related influences as well as similar loads.”

Mosier advised getting drivers with comparable skills levels to run the trucks.

“How many trucks should be run? The more the better, but at a minimum it should be four that are equipped with your evaluation steer tires,” Mosier said. “This will give you good average wear rate data, plus if you lose a tire due to a road hazard, you will still have three vehicles left running.”

Tire placement options should be utilized to maximize testing opportunities.

“As for drive tires, you can test two brands of tires on one vehicle. The only caveat is that their diameters need to be within ¼-inch of each other,” Mosier said. “With this evaluation, you can run two trucks with eight wheel positions. The key is doing an X-pattern (or cross-axle) on the two rear axles.

“However, don’t run the tires identically on the two trucks,” Mosier continued. “The right rear outer tire historically wears faster than any other drive position tire due to a higher percentage of right-hand turns, which can cause scrubbing. Be sure to have brand X in that position on one evaluation truck, and brand Y on the next truck. Also, note that tires on the trailing axle typically wear about 20% faster than tires on the forward axle.”

Wheel choices should be carefully considered along with vehicle condition.

“The wheels being used should be the same size and free of any damage,” Best said.

Total vehicle alignment is recommended. On the day the tires are mounted, the tester will need to record the vehicle’s mileage or engine hours – whichever metric you want to use. Everything should be well documented to maintain records for the testing.”

Data comes rolling in

Though it can be tedious, collecting and recording tire testing data is critical in determining which tires work best. Tire testing tools are critical, too, but they don’t have to be exotic. For instance, Best recommends a calibrated tire pressure gauge, tread depth gauge, pliers, awl, flashlight, tire crayon or chalk, clipboard and forms and a digital camera.

Don’t rush out to switch brands following tire testing. “If, in your evaluation, the test tire outperforms the incumbent, our recommendation is to move forward, but not all the way forward,” said Mosier, shown above. “Your evaluation gave you confidence in the new tire and how it should perform. So, begin to purchase 50% of the ‘new’ tires for six months – both in replacement and through your truck OE if available – and then if all looks good, at a year, move forward on full-tire standardization.”

Don’t rush out to switch brands following tire testing. “If, in your evaluation, the test tire outperforms the incumbent, our recommendation is to move forward, but not all the way forward,” said Mosier, shown above. “Your evaluation gave you confidence in the new tire and how it should perform. So, begin to purchase 50% of the ‘new’ tires for six months – both in replacement and through your truck OE if available – and then if all looks good, at a year, move forward on full-tire standardization.”“The inspection period should be defined by all parties before the test begins,” Best said. “This can vary based on the wear rates of a fleet and the vehicles available for these periodic inspections. It is recommended that only one person take the measurements for consistency.”

Best said this person should record vehicle number, odometer reading, wheel position and unique tire identification number, tire inflation pressure, tread depth measurements (making sure the tread depth gauge is completely at the bottom of the groove), driver comments on tire performance such as wet traction or ride comfort and take pictures of each tire, especially if there are any irregularities.

Testing should begin at roughly the same time to minimize exposure to varying conditions such as seasonal temperatures and weather events, both of which can affect tire performance.

“Once the tires are running, tread depths should be measured at specific intervals,” Fisher said. “Tires on vehicles in over the road operations should be measured at least every 30,000 miles or at scheduled PMs.

“For tires in pickup and delivery service or other high wear conditions, such as construction and refuse operations, use measuring intervals that equate to 25%, 50%, 75% of wear and at removal,” Fisher continued. “These percentages may be based on anticipated mileage or time depending upon the operation’s means for determining tire life.”

Tread wear should be measured at three points across the outside, middle and inside of the tread, Mosier said.

“A fingertip diagnostic should be conducted as well and any signs of irregular wear reported,” Mosier continued. “Irregular wear could indicate a problem with the vehicle. If the irregular wear is found to be severe, in the drive or trailer position, rotate the tires on the front rear axle in cross axle design.”

Testing duration can vary depending on duty cycle but “mileage projections can be made when at least 50% of the tread has been worn, but should only be used as indicators of tire performance,” Fisher said. “Final analysis of performance should be made using actual removal mileage when the tires are worn to the fleet’s pull point.”

Haste makes waste. “Wear conclusions should not be drawn before the tires are at least 50% worn,” said Roger Best, market insights and product applications engineer at Bridgestone Americas. “When drawing conclusions before tires have been removed, keep in mind these numbers are only projections and are not necessarily a representation of removal mileages. Ideally, a test should last long enough for most of the tires to be removed. This gives a more complete picture of actual removal mileages.”

Haste makes waste. “Wear conclusions should not be drawn before the tires are at least 50% worn,” said Roger Best, market insights and product applications engineer at Bridgestone Americas. “When drawing conclusions before tires have been removed, keep in mind these numbers are only projections and are not necessarily a representation of removal mileages. Ideally, a test should last long enough for most of the tires to be removed. This gives a more complete picture of actual removal mileages.”Tire testing results on steer tires vary from other tires.

“After 75,000 miles, you should have solid wear data on your steer tires,” Mosier said. “With this wear data in place, you can now make projections on how many more miles the steers will last before they’re pulled for retreading. This will give you an apples-to-apples mileage comparison and provide your first cost-per-mile figure on virgin rubber, once you factor in the purchase price.”

Getting data from drive tires will take longer, Mosier said, since those tires put on more mileage.

“When tread is worn down by 50% to 60% you can gather your viable data and you can see how many 32nds of tread have been worn off,” Mosier continued. “Once you have miles per 32nd calculated, do the math to see how your test tires are projected to do, plus factor-in what you found on casing value.”

Fisher pointed out, “that tire fuel economy tests can also be done in-house by fleets. Fleets should see TMC’s RP230 Tire Test Procedures for Treadwear, Serviceability and Fuel Economy for instructions on conducting these types of tire tests.”