Donaldson Co., a manufacturer of filtration systems and parts, marked the 10th anniversary of the commercialization of its PowerCore filtration technology and the sale of its 10 millionth filter. PowerCore’s media technology for the heavy-duty offroad and on-road equipment markets is available to first-fit and aftermarket users worldwide.

“Our customers’ need for greater filtration performance in a smaller package drove the demand for Donaldson’s new air filtration technology a decade ago,” says Andrew Dahlgren, general manager of the engine air business unit at Donaldson. “As years passed, we continued to improve the technology, culminating in the release of PowerCore G2. Today, we celebrate the advancements PowerCore has made in air filtration.”

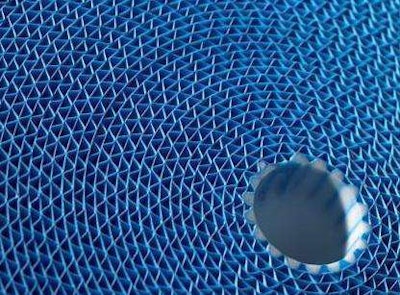

Introduced as an alternative to conventional larger-sized filters, PowerCore’s straight-through airflow design and high-density filtration system helps reduce system restriction, extend filter life and reduce overall maintenance costs. The compact metal-free cartridge-style design traps contaminants inside its structure for cleaner and easier servicing.

“PowerCore’s compact design helps our customers deal with the need to package more and more equipment in the engine compartment,” Dahlgren says. “OEMs can now choose from an array of configurations to meet their design specifications.”

Complementary to this air filtration solution is the incorporation of Ultra-Web nanofiber filter media. Manufactured using a proprietary electrospinning process, Ultra-Web is designed to cause submicron contaminants such as dust and soot to load on the surface rather than disperse throughout the depth of the filter media where pores can clog quickly.

Donaldson says it improved the design further with the introduction of PowerCore’s second generation – PowerCore G2 – in 2008. PowerCore G2 offers the same straight-through airflow and high-density filtration system advantages as the original, with a footprint that’s 30 percent smaller than the original PowerCore design.

“PowerCore G2 took it to the next level,” Dahlgren says. ” Our second-generation solution offers a host of performance advantages to our customers, including smaller size, lower pressure drop and longer filter life. But we’re not finished yet. As underhood space and performance requirements continue to change, we are committed to designing and manufacturing innovative air filtration technologies that will support our customers’ on- and off-road applications.”