A win-win if there ever was one

Why have your used engine oil hauled away when you can use it to heat your shop?

Used engine oil is a terrific fuel, closely resembling No. 2 diesel fuel and furnace oil – except that it actually contains more energy. Its Btu content per gallon is 150,000 versus 138,000 for furnace oil.

All Reznor units have integral air compressors, a small piston-type unit that needs no oil, and an integral air filter that should be cleaned periodically.

All Reznor units have integral air compressors, a small piston-type unit that needs no oil, and an integral air filter that should be cleaned periodically.When considering a waste oil-fired heater, the first question to answer relates to oil supply. A minimum of 500 gallons of waste oil per year is preferable, says Tina Phillips, international sales and marketing manager for Clean Burn.

Lanair sales manager Tom Francois says shops relying on a waste oil heater as the primary heat source can go through 3,000 to 6,000 gallons every winter. “It depends entirely on how large a building is and what size heater is needed to heat that area,” Francois says. Running 10 trucks 100,000 miles per year and changing oil at 25,000 miles equates to 440 gallons per year if the trucks’ sumps hold 11 gallons.

‘We’re talking about serious potential savings.’

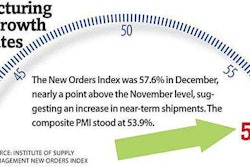

– Kent Freeman, Innovative Resources

However the math works out, “we’re talking about serious potential savings” for fleets, says Kent Freeman of Innovative Resources, manufacturing representative for Reznor and its dealers. Consider that 3,600 gallons of used oil equates to $12,600 of No. 2 oil priced at $3.50 per gallon, even ignoring the higher heating value of used engine oil.

Heater specs

When sizing a shop furnace, many factors must be considered, such as the cubic dimensions of the area to be heated, the average outside temperature during the winter, how well the building is insulated, the number of bay doors and how often they are open during the day. If a 2,000-square-foot building with a 14-foot-high ceiling has ceiling insulation only and has an average outside temperature of 20 degrees Fahrenheit during the winter, a small unit providing 110,000 Btu is recommended, Phillips says. Units providing up to 500,000 Btus are available from most suppliers.

Another choice is whether to go with a warm air heater or a boiler. Heater models often have an integral fan and circulate the air directly from the unit onto the shop floor; also available are models for ducted systems where the air must be sent a good distance from the heater or into separate spaces such as offices or lavatories.

Boilers aren’t designed to heat an open area and often are used for more direct heating applications such as car and truck washes and radiant floors and baseboards to melt snow and ice.

Installation, maintenance

The unit should be installed inside where the weather won’t cause the oil to jell, even though some heater suppliers allow outside tanks. An air line with the correct diameter is required and must be equipped with the proper pressure regulator that brings shop air pressure down to a much lower level, as well as a water trap or extractor/dryer to ensure that only dry air gets to the burner.

A 50-psi regulator must be in the line, and a secondary regulator must be on the units to control pressure at 18 psi at the burner. The air requirement is about 2 cfm, so there won’t be much of an impact on shop air.

Less costly systems often will pay for themselves in as little as two years. And not only will fleets eliminate a lot of heating fuel costs, they also won’t have to pay someone to haul their used oil away.