In April, 2014, the American Transportation Research Institute released the first of what will likely be an annual study on how congestion impacts the trucking industry. ATRI has compiled a database of 12 years of truck position data to facilitate research.

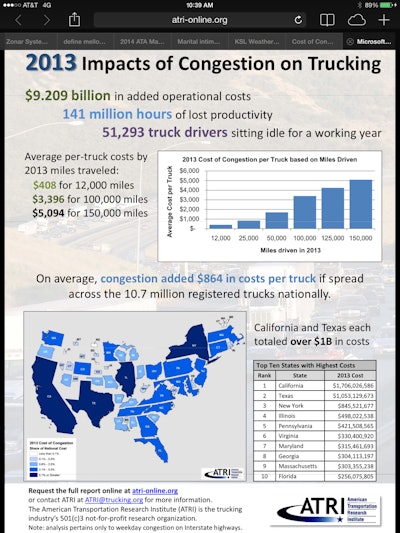

On the interstate system alone, trucking companies lost 141 million hours of productivity in 2013, which is the equivalent of more than 51,000 truck drivers being idle for one year, the study found.

“In a time when we struggle to put drivers in seats, we can ill afford to have 50,000 plus drivers just sitting still,” said Rebecca Brewster, president and chief operating officer of ATRI.

Fleet executives on the panel discussed some short-term strategies to help mitigate the impact of traffic congestion.

D.M. Bowman, Inc. is a full-service, diversified motor carrier that operates 350 trucks. Panelist Jim Ward, president and chief executive of the Baltimore, Md.-based company, said the density of its regional shipping lanes help improve efficiency. The company is able to increase productivity by having a nighttime shift to avoid congestion points.

D.M. Bowman also uses research from ATRI and other sources to identify the major traffic bottlenecks by location and time of day. It monitors the velocity of loads in its system from pickup to delivery to identify conditions that can be improved.

CLICK image to access the 2013 cost of congestion report from ATRI

CLICK image to access the 2013 cost of congestion report from ATRI“We try to dispatch at an average of 50 miles per hour,” he said. The data it collects from electronic logging devices (ELDs) has helped to improve trip planning as well.

“We are better planners today than we have ever been before as a result of that information,” he said. “We are armed with better data than we probably had before to go into our customers and explain to them what we are seeing in some of these lanes and why velocity is so important to us.”

Kevin Knight, chairman of the board and chief executive of Phoenix-based Knight Transportation, said a focus of his company and the industry needs to be improving the flow of shipments from one customer to the next to avoid congested traffic lanes when possible.

Knight also said he strongly believes in legislation to increase fuel taxes and create additional fees for motor carriers and passenger vehicle to utilize the nation’s highways.

Panelist Tracy Rosser, senior vice president, transportation and supply chain for Wal-Mart, said the company is focused on things it can control to increase efficiency. The company’s private fleet operates more than 6,000 trucks and runs about 650 million miles per year.

In 2005, the company set a goal to double fleet efficiency by 2015. It has accomplished 84 percent of that goal by moving 700 million more cases over 300 million fewer miles.

“We think that anything we can do to help mitigate congestion will actually help our customer’s pocketbook,” he said.