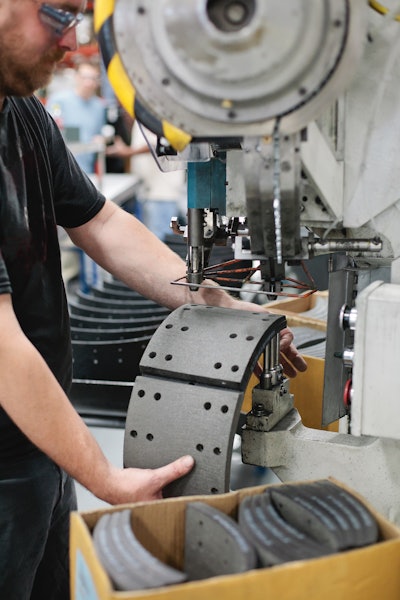

The facility handles the complete salvage, coining, and assembly processes that make up start-to-finish brake shoe remanufacturing in Huntington.

“The National Highway Traffic Safety Administration’s Reduced Stopping Distance (RSD) mandate, which took full effect in 2013, ushered in a new era of stopping requirements (under FMVSS-121) for drum brakes,” says Keith McComsey, Bendix director of wheel-end marketing and customer solutions. “In servicing these brakes, more and more vehicle operators are choosing RSD-compliant remanufactured shoes from a trusted original equipment (OE) supplier to preserve that high level of safety.”

McComsey adds Bendix achieves OE quality in its reman brake shoes by bringing them back to full OE specifications, rather than just relining them.

In addition to the RSD mandate, trucking today is also influenced by the Federal Motor Carrier Safety Administration’s (FMCSA) Compliance, Safety, Accountability (CSA) program. With it has come a focus in the commercial vehicle industry on CSA scores.

Refining a reman process that produces brake shoes meeting OE specs is crucial to maintaining brake safety and performance in this demanding environment, says Earl Brown, product manager, Reman Brake Shoes, Bendix.