North American Class 8 trucks saw orders decline again in November, according to preliminary net orders from FTR Transportation Intelligence and ACT Research.

FTR reported orders declined more sharply than normal seasonal patterns, falling 17% from October and 44% from the prior year to reach 20,200 units. The figure is significantly below the historical 10-year November average of 28,910 units. Orders have totaled 214,797 units over the last 12 months.

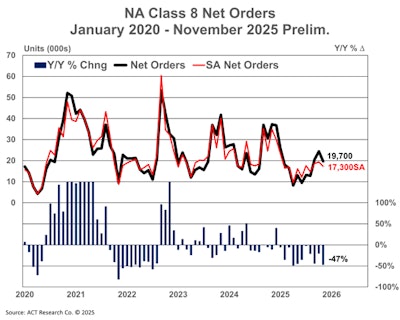

ACT estimated that Class 8 orders reached 19,700 units in November, down 47% from last year, with combined Classes 5-8 totaled at 36,000 units, indicating a 33% year-over-year decrease.

The downturn continued despite recent modest improvements in tariff and regulatory policies. FTR said that's because fleets continue to take a cautious stance on replacement and expansion plans due to weak freight demand, excess capacity, high costs for financing and equipment, and other headwinds.

Both vocational and on-highway segments saw sequential and year-ago declines, FTR said, though vocational orders held up better on an annual basis, suggesting “continued, but cautious demand” heading into 2026.

FTR had expressed concerns for the 2026 order cycle. Cumulative net orders from September through November were down a striking 36% year over year. However, the industry now has better visibility around tariff impacts on heavy-duty trucks and likely changes in the Environmental Protection Agency’s 2027 NOx rule.

The tariff framework increases costs, FTR said, but in a controlled way that encourages reshoring without creating short-term disruptions to Class 8 sourcing and production.

FTR noted that the likely removal of the extended warranty requirements from the NOx rule could potentially cut costs, likely by around half of the previously expected increase.

However, improved clarity hasn’t been enough to overcome other obstacles in the industry, such as weak freight market fundamentals, limited carrier profitability and expensive capital, said Dan Moyer, FTR’s senior analyst for commercial vehicles.

Fleets are still prioritizing cost control, equipment maintenance and asset utilization, delaying purchasing decisions and any meaningful rebound, Moyer pointed out.

“For truck manufacturers and suppliers, forward visibility remains limited, and order activity is likely to remain uneven until freight volumes and rates show a sustained recovery,” he said.

Carter Vieth, research analyst at ACT Research, echoed similar sentiments. Though recent EPA announcements offered clarity, he said “the obvious bottleneck to stronger order activity is lack of carrier profitability.”

“Spot rates continue to tread along the bottom, and while supply is coming out of the market, demand in key freight sectors is lagging,” Vieth added.

In the medium-duty segment, Vieth added that November orders for Classes 5-7 decreased 2.9% year over year to 16,300 units. The segment continues to feel pressure from small businesses “getting crushed by tariffs, uncertainty and levels of consumer pessimism typically reserved for recessions.”