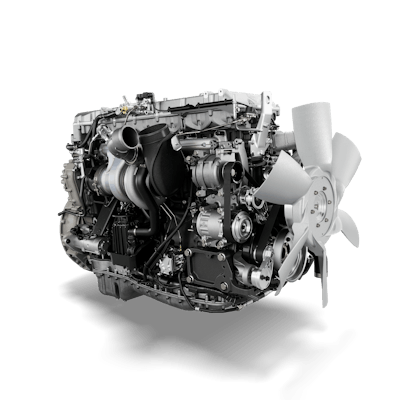

Exceptional fuel efficiency, a better driver experience, lower maintenance costs because of a simpler design and reliability: that’s International Motors’ elevator pitch for its S13 integrated powertrain, which has penetrated the market more substantially over the past year.

The company expects those benefits to increase when it rolls out its 2027 powertrain. The new model is set to meet the U.S. Environmental Protection Agency's (EPA) heavy-duty commercial vehicle emissions requirements—limited to 0.035 grams of nitrogen oxide (NOx)—with only minor refinements to the existing product.

“By designing with future regs in mind, we believe we've got a very strong and compelling offering for our 2027 solution,” David Hillman, International’s vice president of integrated technology sales, told the media during a virtual event on Wednesday.

The 2027 version carries over 90% of the hardware from the current platform, maintaining consistency in service tools, parts, and technician training. The new or updated elements for the 2027 powertrain, which is composed of the S13 engine, T14 transmission, and dual-stage aftertreatment system, include:

- S13 engine: Variable Valve Timing (VVT) with the addition of a hydraulically actuated clutch feature for valve actuation; Variable Valve Braking (VVB) for improved performance; a closed crankcase breather to prevent venting to the atmosphere (an EPA 2027 requirement); and an oil centrifuge to maintain existing maintenance practices regarding oil drain intervals.

- T14 transmission: A 24V Transmission Control Module featuring predictive shifting using GPS and topography data.

- Electrical architecture: Reduced complexity via a standardized 24V electrical architecture across the entire powertrain platform. This includes a 24V alternator, starter, and engine controllers for improved cold-crank performance and durability, while retaining a 12V cab and chassis electrical system for battery accessories and body controls.

Regarding the aftertreatment system, Hillman noted that while some sensors and wiring will be adapted to 24V, the overall shape, size, and weight will remain neutral. International is not introducing a 48V electrically operated grid heater, as it is unnecessary for this powertrain.

“We do expect to have the lightest-weight offering in the 13L space,” Hillman said. “While others are getting perhaps more complicated, we are simplifying our design... We believe we are bringing the least disruptive technology to the marketplace to meet the 2027 regulations.”

Hillman attributed this to International’s investment in developing its own in-house powertrain, made possible by the Traton Group’s acquisition of the company (formerly Navistar).

Catrina Mitchell-Adegbemi, International’s senior vice president and chief technology officer, said the deal allowed International to design the new powertrain from scratch.

“We had multiple brands come together across the globe under one vision for our powertrain to be globally developed but locally validated,” Mitchell-Adegbemi said. “Instead of trying to adapt outdated technology to make it work, we had an opportunity to take the best innovation from around the group and build this from the ground up.”

This approach also enabled International to eliminate the EGR cooler—a feat Hillman noted not every manufacturer can achieve because it requires a “clean-sheet design.” The 2027 engine will eliminate EGR usage altogether. While there is no EGR cooler on the current S13, it does feature an EGR crossover tube used during idling.

International Executive Vice President of Commercial Operations Dan Kayser said the 2027 S13 integrated powertrain is not yet for sale, but he anticipates it will be available for order by mid-year.

The trucking remains concerned about price increases related to 2027 EPA-compliant engines. Kayser could not yet offer pricing information for the 2027 S13, noting that there are “still some factors playing out.” The EPA, which is re-evaluating the 2022 Heavy-Duty Engine and Vehicle rule, has yet to share its revised plan.

“There are costs associated with the new emissions standards that aren't just the product,” Kayser said. “We don't have great clarity yet on those pieces... so until we can understand all the rules and regulations, I can't answer that question for sure.”

However, Hillman emphasized that by designing with future regulations in mind, the 2027 product has a shorter path to meeting EPA standards. International also benefited from product and process commonality across the Traton Group, which Mitchell-Adegbemi said allowed the company to be more efficient with its development investments. Furthermore, International has received positive feedback regarding fuel efficiency from customers who have logged over 700 million cumulative miles on the current powertrain. These savings have made the S13 an attractive option, which Kayser noted has already attracted new customers.

“Our customers see the tangible results, specifically in spending less on fuel,” Kayser said. “We hear customers saying, ‘I'm stopping less to fuel the truck,’ which makes the operation more efficient.”

Hillman concluded that removing the EGR cooler, along with using a fixed geometry turbo, a dual overhead cam design, and a 23:1 compression ratio, helped International deliver a lightweight package and superior fuel economy. The 2027 solution will follow this same philosophy.

Whether these factors will grant International a competitive advantage or a lower price tag remains to be seen.