Introduced Sunday at ATA’s Technology & Maintenance Council (TMC) Annual Meeting in Atlanta, STEMCO President Todd Anderson says Trifecta is unique, and features the industry’s first Discover XR (extreme runtime) wheel seal with GlideLock technology. According to STEMCO and Webb Wheel, the seal glides on and is self-locking, reducing installation force by 50 percent, with no prelube required. In combining the Discover XR with Webb Wheel’s hub and the Defender composite hub cap provides the industry’s best contamination and corrosion resistance.

“Trifecta is the latest innovation to combine safety, performance and confidence into one complete package,” says Mark Holley, segment business leader of wheel end products for STEMCO. “By combining STEMCO manufactured products with patented technology, the assembly is uniquely developed to extend wheel end life while providing unmatched contamination prevention.”

The Trifecta assembly also features STEMCO’s Zip-Torq fully unitized axle spindle nut, increasing simplicity and safety for end users. According to the companies, there are no additional clips, keepers, snap rings or screws to install. The self-ratcheting locking feature prevents inadvertent back-offs. Additionally, installation of the new hub assembly requires no bearing adjustment, ensuring the hub is installed correctly, quickly and easily.

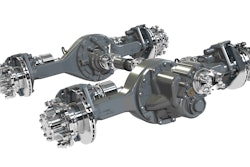

Anderson says Trifecta installation time is considerably shorter than industry averages, and the hub assembly may be used on drive, steer and rear axles.

STEMCO is accepting pre-orders now, and the product will be available in the second quarter. Trifecta also features a five-year, 500,000-mile warranty for on-highway applications and a a three-year, 350,000-mile for vocational applications.