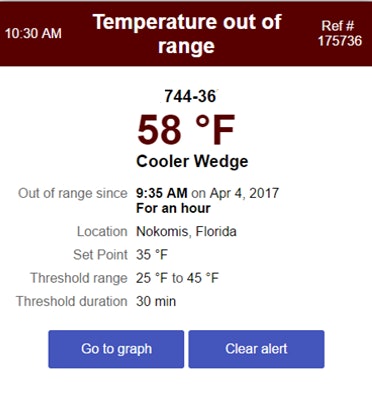

Cooltrax’s product line includes a Wedge device that inserts into cargo to determine if the temperature is out of range.

Cooltrax’s product line includes a Wedge device that inserts into cargo to determine if the temperature is out of range.Cooltrax, a cold chain visibility provider, announced that broadline foodservice distributor Cheney Brothers has completed implementation of its Cooltrax Fresh inTransit wireless temperature monitoring and management system.

With the Cooltrax Fresh inTransit system, Florida-based Cheney Brothers has improved visibility and real-time data about the handling of temperature-controlled products for its fleet of 700 tractor-trailers.

The technology allows independent temperature and product-level monitoring as well as reefer trailer data. Since trailer doors are opened and closed frequently, close monitoring of food temperatures is required to prevent deliveries from being rejected.

“Cooltrax Fresh inTransit far exceeded the market standards for data during the pilot program,” said Mike Sharpe, president of Cooltrax North America. “We also worked closely with Cheney Brothers to implement critical product-level temperature monitoring that, ultimately, changes the game.”

With the Cooltrax Business Intelligence dashboard, Cheney Brothers is able to monitor product-level temperatures within custom pre-defined ranges; have direct visibility into the speed and location of product movement; know the timing and duration of door-opening activity; and more.

“We’re able to look at route inefficiencies in real time, maximize the capacity of our trailers and deliver our customers a better service,” said Keith Sanders, senior warehouse management system manager, Cheney Brothers. “Our customers depend on us to be reliable and consistent in the products we deliver now more than ever. Through our partnership with Cooltrax, we exceed these expectations every single day.”